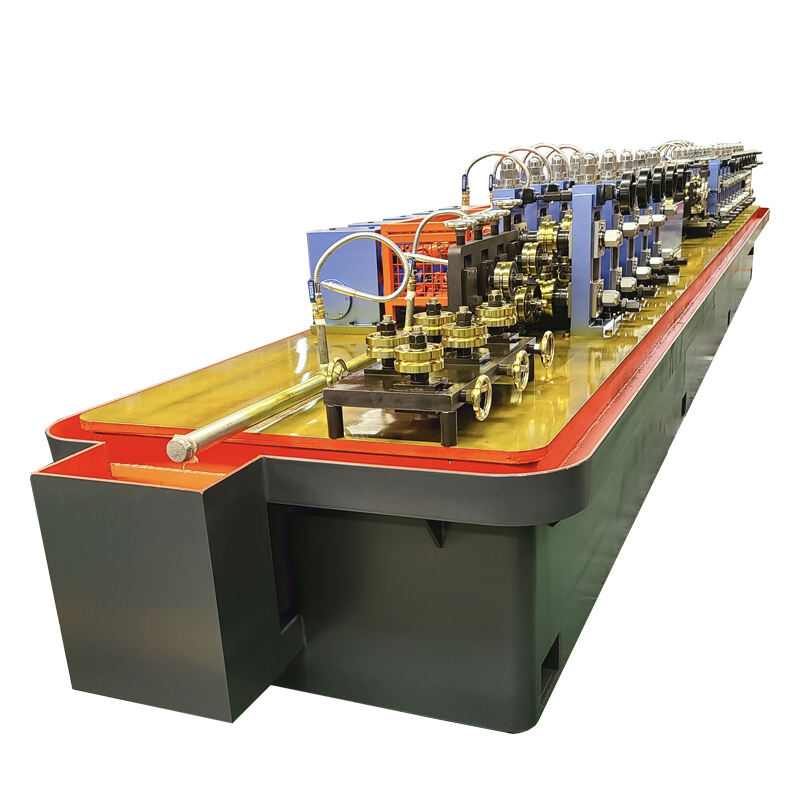

durable ms tube making machine

The durable MS tube making machine represents a cutting-edge solution in metal tube manufacturing, designed to deliver exceptional performance and reliability in producing mild steel tubes. This sophisticated equipment combines advanced technology with robust construction to ensure consistent, high-quality output. The machine features a comprehensive production line that includes uncoiling, leveling, forming, welding, sizing, and cutting processes, all integrated into a seamless operation. Its precision-engineered forming stations gradually shape flat steel strips into perfectly rounded tubes, while the high-frequency welding system ensures strong, uniform seams. The machine's automation capabilities allow for rapid adjustments in tube dimensions, making it versatile enough to handle various specifications ranging from 20mm to 76mm in diameter. The integrated quality control systems monitor every aspect of production, from material feeding to final cutting, ensuring each tube meets stringent industry standards. Operating at speeds of up to 40 meters per minute, this machine maintains exceptional accuracy while delivering impressive productivity rates. The robust construction, featuring hardened steel components and precision bearings, ensures minimal maintenance requirements and extended operational life. This machine is particularly suited for manufacturing tubes used in construction, furniture making, automotive components, and various industrial applications.