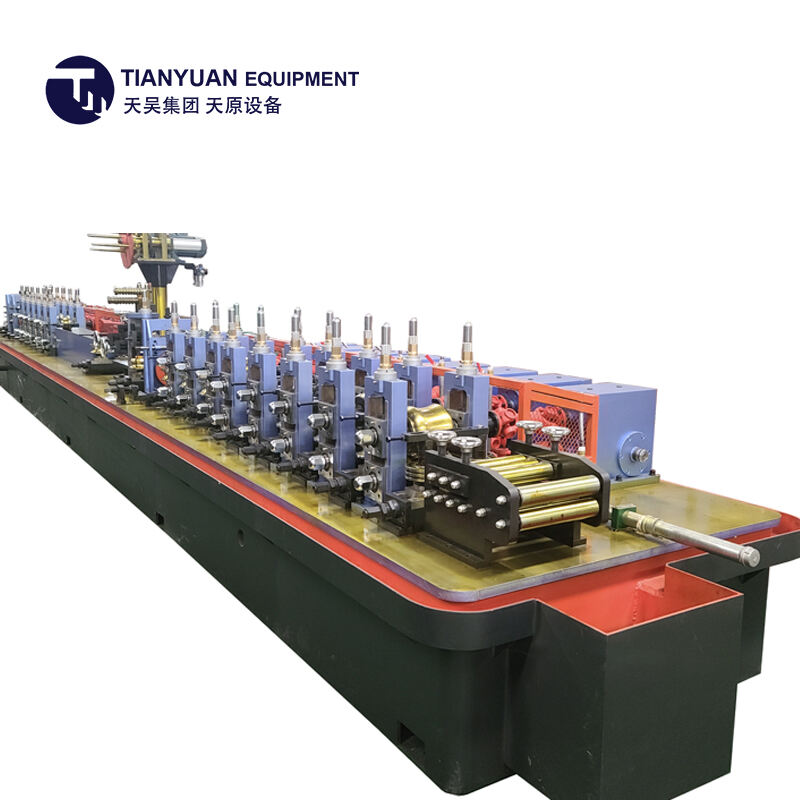

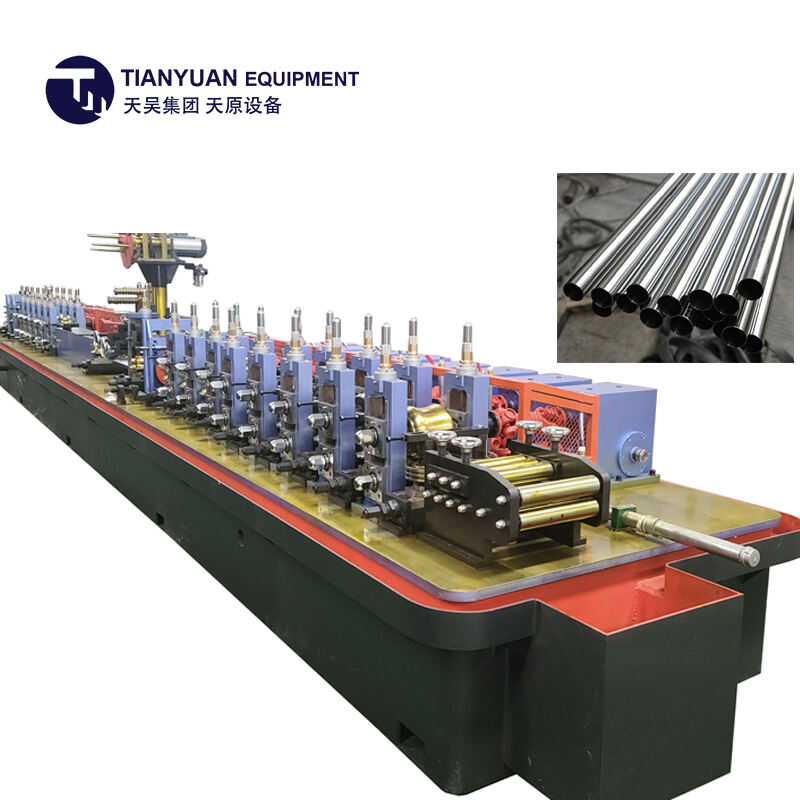

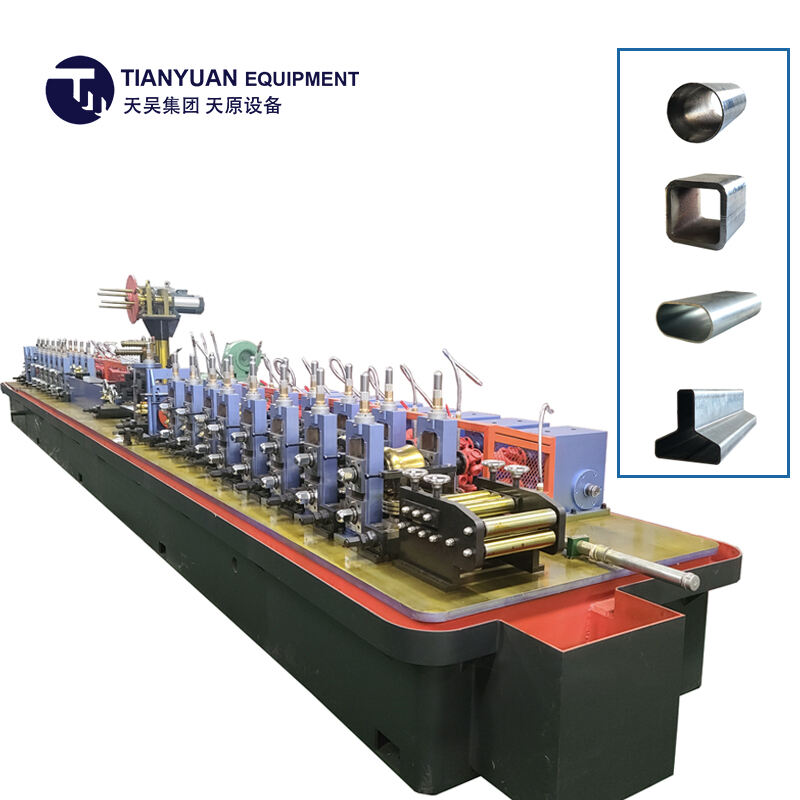

safe carbon steel pipe making machine

The safe carbon steel pipe making machine represents a cutting-edge solution in modern industrial manufacturing. This advanced equipment efficiently produces high-quality carbon steel pipes through a sophisticated process that combines precision engineering and automated control systems. The machine incorporates multiple stages, including material feeding, forming, welding, sizing, and finishing, all integrated into a seamless production line. Its state-of-the-art technology ensures consistent pipe dimensions, superior weld quality, and excellent surface finish. The machine can handle various pipe specifications, with diameter ranges typically from 20mm to 219mm and wall thicknesses from 1.5mm to 6mm. Advanced safety features include emergency stop systems, protective guards, and intelligent monitoring systems that continuously track production parameters. The machine's PLC control system enables precise adjustments and real-time process monitoring, ensuring optimal production efficiency and product quality. Applications span across multiple industries, including construction, oil and gas, water supply, and general industrial piping systems. The machine's versatility allows for quick specification changes, making it suitable for both mass production and customized manufacturing requirements.