سعر ماكينة صنع أنابيب السيارات

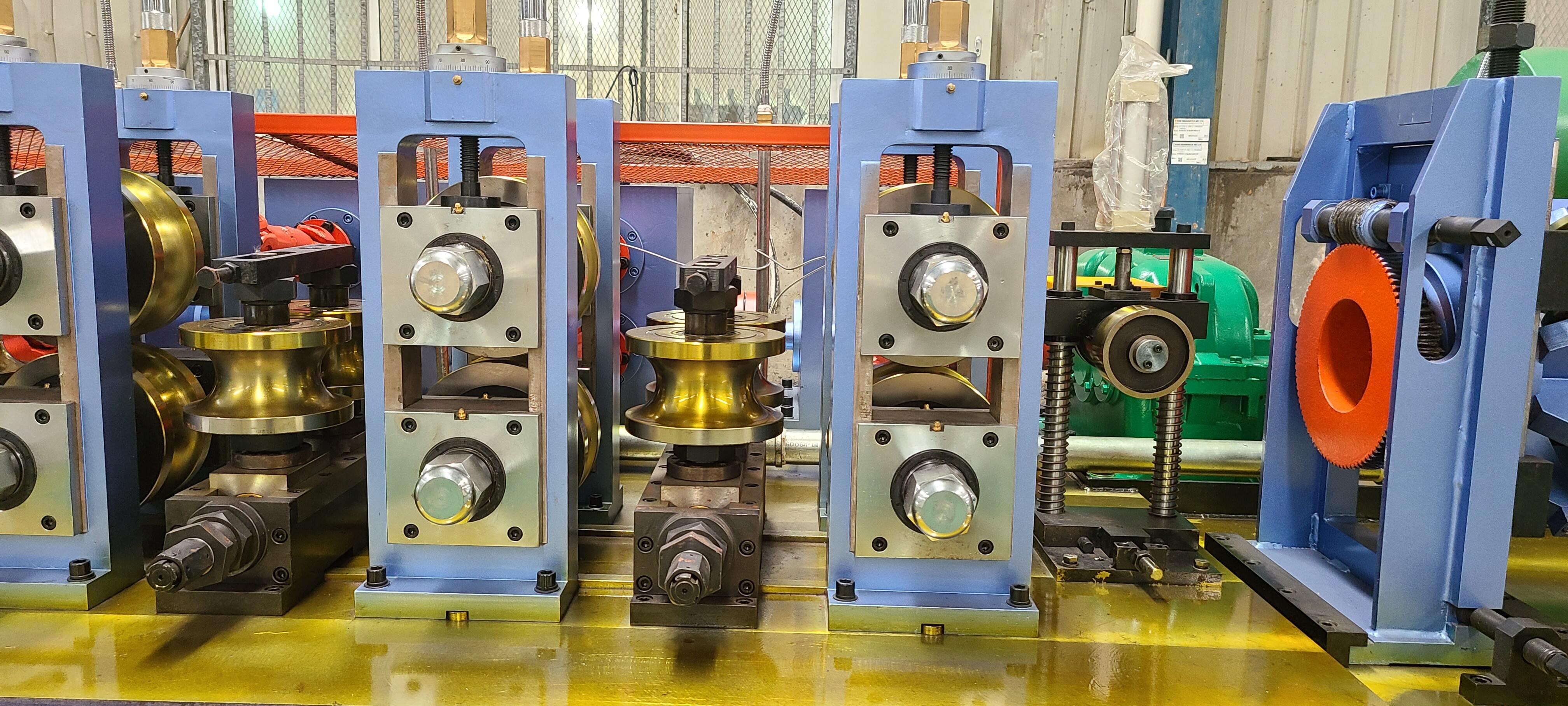

يمثل سعر جهاز صنع أنابيب السيارات اعتبارًا حاسمًا للمصنعين في صناعة مكونات السيارات. هذه المعدات المتقدمة، المصممة لتصنيع دقيق لأنواع مختلفة من أنابيب السيارات والمكونات الأنبوبية، تجمع بين التكنولوجيا المتقدمة وقدرات إنتاج اقتصادية. عادةً ما تحتوي الآلة على أنظمة تحكم الكمبيوتر، مما يتيح الدقة العالية في الأبعاد وجودة الإخراج المستمرة. يمكنها التعامل مع أقطار الأنابيب المختلفة والمواد، بما في ذلك الصلب، الألمنيوم، والسبائك النحاسية، مما يجعلها متعددة الاستخدامات لمختلف التطبيقات السيارات. يتباين نطاق السعر بشكل كبير بناءً على المواصفات، قدرة الإنتاج، ومستوى التلقائيه، عادةً ما يتراوح بين 50,000 إلى 200,000 دولار. هذا الاستثمار يعكس الوظائف الشاملة للآلة، بما في ذلك قدرات القطع والتقويس وتشكيل الأطراف تلقائيًا. تتضمن الوحدات الحديثة محركات موفرة للطاقة وأنظمة مراقبة ذكية، مما يقلل من تكاليف التشغيل مع الحفاظ على معايير الإنتاج المرتفعة. تصميم الجهاز القابل للتوسيع يسمح بالترقيات والتعديلات المستقبلية، مما يحمي الاستثمار الأولي بينما يتكيف مع احتياجات التصنيع المتغيرة.