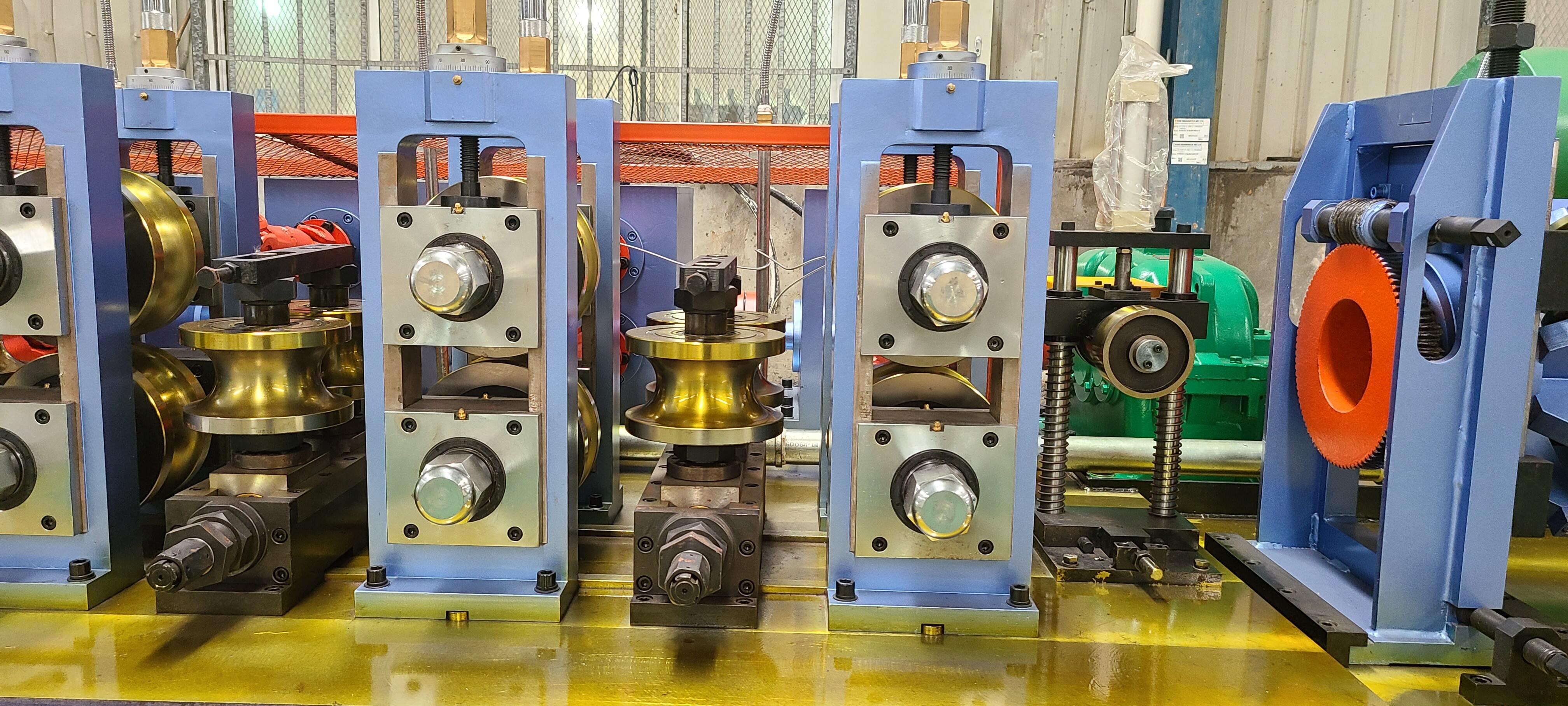

avtomobil tübyu hazırlama maşını

Avtomobil tüpü istehsal etmək maşını, yüksək keyfiyyətli avtomobil tüpləri elementlərini istehsal etmək üçün xüsusi olaraq dizayn edilmiş müxtəlif bir istehsal təchizatıdır. Bu inkişaf etmiş texnikada, ham materialları müəyyən, dayanıklı tüplərə çevirmək üçün ən yaxşı texnologiyalar integrasiya edilib, bu da müxtəlif avtomobil tətbiqləri üçün vacibdir. Maşın sistematik proses istifadə edir ki, bu materialların yüklənməsi ilə başlayır və daha sonra dəqiq formalaşdırma, qovma və tamamlama əməliyyatlarını izləyir. Bu, üsulü dəqiqliyi saxlayıb yüksək effektivlik səviyyələrini qoruyan avtomatlaşdırılmış idarəetmə sistemləri ilə təmin olunur. Maşının universallığı, çərçivə, alüminium və digər avtomobil istehsalında ümumiləşmiş metallar daxil olmaqla fərqli materialları işləməsinə imkan verir. Onun inkişaf etmiş kalibrasiya sistemi, hər tübin müəyyən nömrələrə uyğunu saxlamağa və avtomobil tətbiqləri üçün vacib olan striktni toleransları qorumağa kömək edir. Təchizatda formalaşdırma, qovma, soxutma və keyfiyyət yoxlaması üçün bir neçə stansiya var ki, hamısı endirilməmiş dəqiqlik ilə işləyib və endirim məhsulları təmin edir ki, bu da sənaye standartlarına uygundur. Robust konstruksiya və güvəndirici performansla, maşın, dəqiqlik ölçülərini və səth keyfiyyətini saxlayaraq yüksək həcmli istehsal ortamında təxminən işləyə bilər. Sistem, onu effektiv və operator-un rahatlıqlı edən təhlükəsizlik elementlərini və acil idarəetmə kontrollərini də əhatə edir.