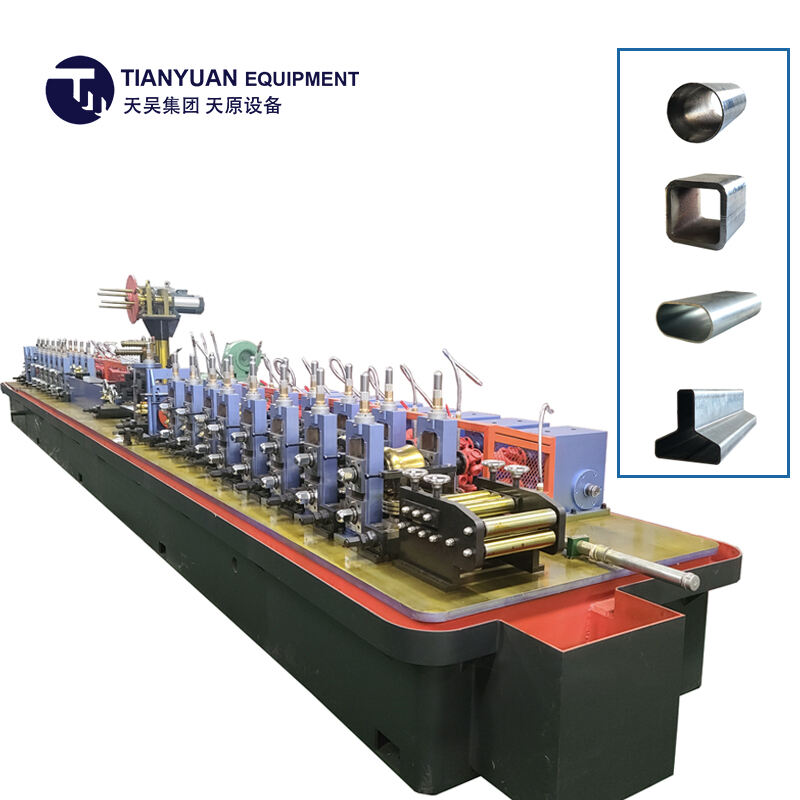

চাইনা এমএস টিউব তৈরি মেশিন প্রযোজক

চাইনা MS টিউব তৈরি মেশিনের প্রস্তুতকারকরা নিজেদের স্থাপন করেছে উন্নত টিউব উৎপাদন সরঞ্জামের প্রধান প্রদাতারূপে। এই প্রস্তুতকারকরা উচ্চ-গুণবत্তার মিল্ড স্টিল টিউব উৎপাদনের জন্য সম্পূর্ণ সমাধান প্রদান করে যা স্বয়ংক্রিয় এবং নির্ভুল উৎপাদন প্রক্রিয়া ব্যবহার করে। এই মেশিনগুলোতে সর্বনवীন প্রযুক্তি অন্তর্ভুক্ত হয়েছে, যা উন্নত আটকানো ব্যবস্থা, নির্ভুল আকৃতি গঠন মে커নিজম এবং উন্নত নিয়ন্ত্রণ ব্যবস্থা বৈশিষ্ট্য ধারণ করে যা নির্দিষ্ট উৎপাদন গুণবত্তা নিশ্চিত করে। এই উৎপাদন ব্যবস্থাগুলো বিভিন্ন টিউব বিন্যাস প্রক্রিয়া করতে সক্ষম, ছোট ব্যাসের পাইপ থেকে বড় শিল্পীয় টিউব পর্যন্ত, যা বিভিন্ন শিল্পের প্রয়োজনের জন্য বিভিন্ন মোটা হওয়ার সুযোগ দেয়। এই মেশিনগুলোতে সাধারণত বহু পর্যায় অন্তর্ভুক্ত হয়: খোলা, রিব প্রস্তুতি, আকৃতি গঠন, আটকানো, আকৃতি নির্ধারণ, সোজা করা এবং কাটা। চীনা প্রস্তুতকারকদের আধুনিক MS টিউব তৈরি মেশিনগুলোতে PLC নিয়ন্ত্রণ ব্যবস্থা অন্তর্ভুক্ত হয়েছে, যা স্বয়ংক্রিয় চালনা এবং উৎপাদন পরামিতির বাস্তব-সময়ের পর্যবেক্ষণ সম্ভব করে। এছাড়াও এখানে উন্নত আটকানো প্রযুক্তি অন্তর্ভুক্ত হয়েছে, যা উচ্চ-ফ্রিকোয়েন্সি আটকানো বা ইলেকট্রিক রিজিস্টেন্স আটকানো ক্ষমতা ধারণ করে, যা শক্তিশালী এবং নির্ভরশীল সিল গুণবত্তা নিশ্চিত করে। এই মেশিনগুলো দীর্ঘ সেবা জীবন এবং কম রক্ষণাবেক্ষণের প্রয়োজন নিশ্চিত করতে উচ্চ-গ্রেডের উপাদান এবং উপাংশ ব্যবহার করে তৈরি করা হয়। এই উৎপাদন সমাধানগুলো বিভিন্ন শিল্পের জন্য উপযোগী, যা রাস্তা নির্মাণ, গাড়ি, ফার্নিচার এবং বাস্তব উন্নয়নের জন্য ব্যবহৃত হয়, যা বিশেষ উৎপাদন প্রয়োজনের জন্য স্বায়ত্ত বিকল্প প্রদান করে।