kiinalaiset putkien muotoilukoneiden valmistajat

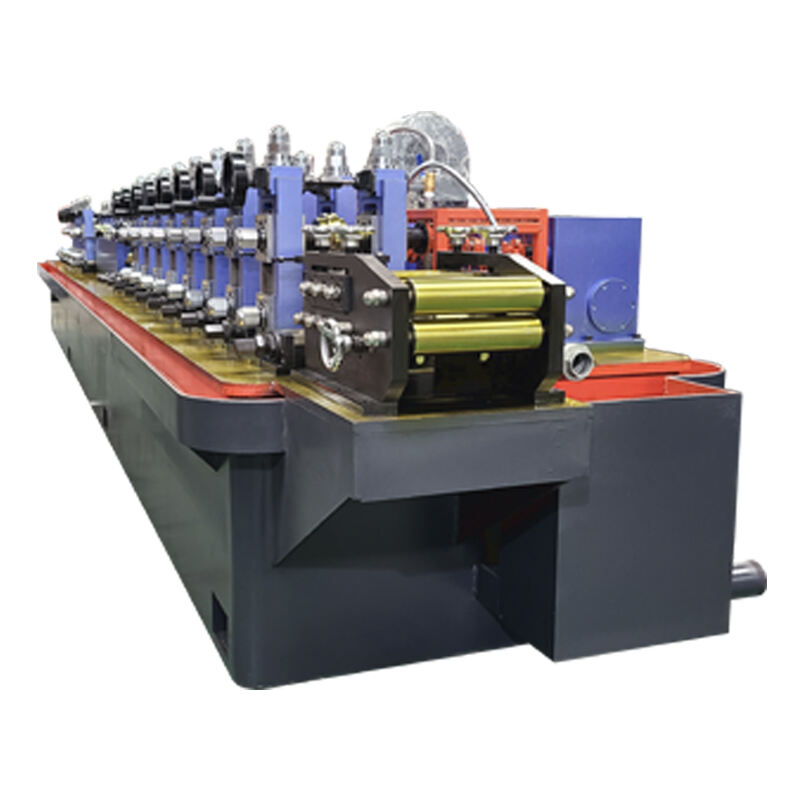

Kiinan putkien muotoilukonevalmistajat ovat vahvistaneet asemansa globaaleina johtajina erilaisten teollisuuden tarpeisiin soveltuvan korkealaatuisen, tehokkaan laitteiston tuonnossa. Nämä valmistajat yhdistävät edistyksellisen tekniikan ja taloudellisen tuotantomenetelmän luodakseen koneita, jotka suorittavat tarkkaa putkien muotoilua. Heidän tuotteensa sisältävät uusimman hallintojärjestelmän, automatisoidut toiminnot ja monipuoliset käsittelymahdollisuudet, jotka kykenevät käsittelemään erilaisia materiaaleja ja määritelmiä. Koneet on suunniteltu useilla muotoilusasijoilla, mikä mahdollistaa erilaisten muotojen ja kokojen putkien jatkuvan tuotannon. Ne sisältävät edistyksellisiä leikkausjärjestelmiä, tarkkoja kaarettamistoimintoja ja kehittyneitä liimaustechnoalogioita varmistaakseen johdonmukaisen tuotteen laadun. Nämä valmistajat ovat kehittäneet kattavia ratkaisuja, jotka sisältävät esimuotoilun, päämuotoilun, koon muuttamisen ja lopputöimituksen, kaikki integroituina yhdeksi tuotantolinjaksi. Laitteisto on rakennettu kestavuutta ajatellen, hyödyntämällä korkealatuisia materiaaleja ja komponentteja, jotka takaa pitkän aikavälin luotettavuuden ja vähemmän ylläpitotarpeita. Monet valmistajat tarjoavat myös mukauttamisvaihtoehtoja vastaamaan erityisiä teollisuuden tarpeita, olipa sitten autoteollisuus, rakennusala, meubelivalmistus tai muita sektoreita. Heidän koneensa on varustettu modernilla turvallisuusominaisuuksilla ja ne täyttävät kansainväliset valmistusstandardit, mikä tekee niistä sopivia maailmanmarkkinoille.