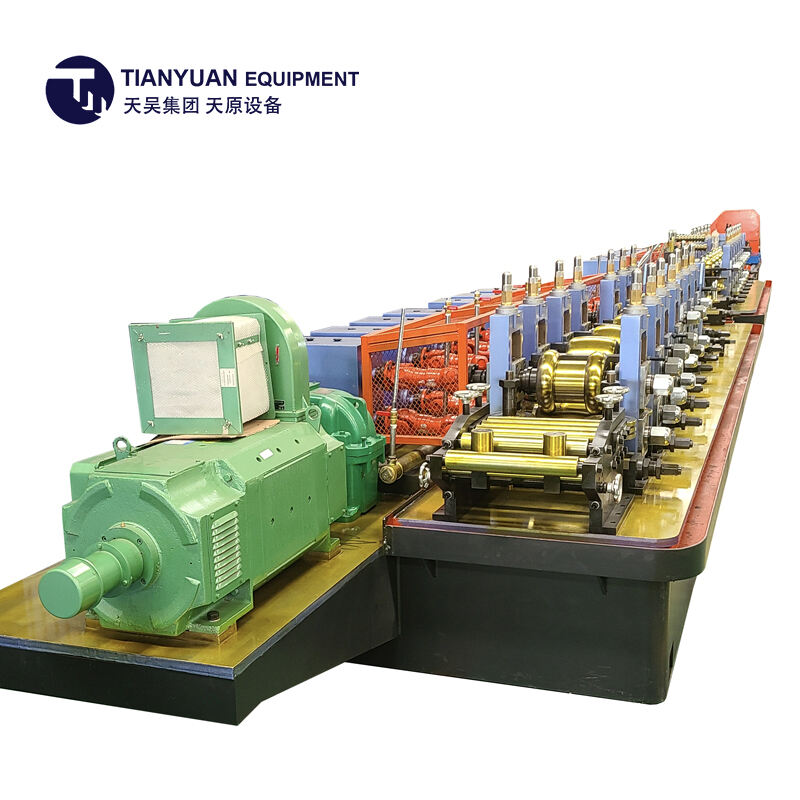

matalan hinnan putkien muotoilukone

Matalan hinnan putkien muotoilukone on kustannustehokas ratkaisu valmistajille, jotka etsivät tehokkaita putken tuotantokykyjä. Tämä monipuolinen laite muuntaa tasoisia metaliplaatteja tarkkoja sylinterimuotoisia kappaleita järjestelmällisellä väännösmenetelmällä. Sen edistyneiden ohjausjärjestelmien avulla se ylläpitää vakavaa laatua samalla kun minimoi materiaalihenkilöiden määrää. Koneella on säädettävät muotoilusatamat, jotka vääntävät metallia vähitellen haluttuun putkemuotoon ja kykenevät tuottamaan erilaisia putkien halkaisijoita ja pituuksia. Sen vahva rakennus sisältää terästettyjä väännösjoukkia ja tarkasti asetettuja muotoilumallia, mikä varmistaa kestävyyden ja mitallisen tarkkuuden. Automatisoitu syöttöjärjestelmä nopeuttaa tuotantoa, kun taas leikkausmekanismi toimittaa puhtaita ja tarkkoja päänteitä. Se sopii sekä pienille työhuoneille että teollisuusyksiköille, ja tämä kone on erinomainen putkien valmistamiseen rakentamista, meubelivalmistusta, autoteollisuuden komponentteja ja maataloussovelluksia varten. Käyttäjänystävä liittymä mahdollistaa käyttäjien helposti säätää parametreja, kuten nopeutta, painetta ja mitallisia määritelmiä, mikä tekee siitä sopeutuvan eri tuotannon tarpeisiin. Vähäisten huoltotarpeiden ja luotettavan suorituskyvyn avulla matalan hinnan putkien muotoilukone toimittaa ammattimaisia tuloksia samalla kun säilyttää taloudellisen tehokkuuden.