machine de fabrication de tubes GI bon marché

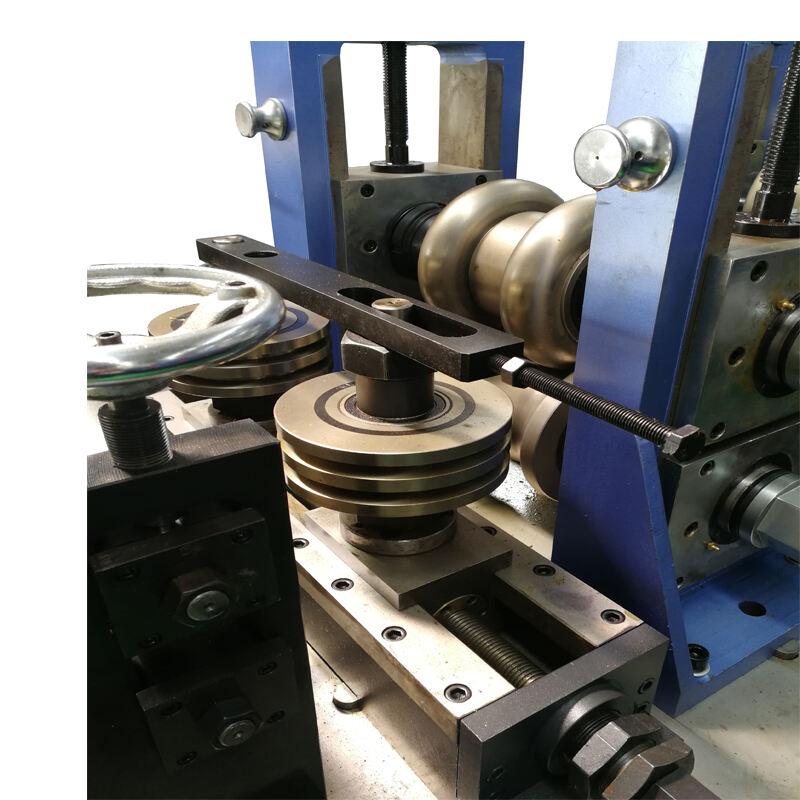

La machine de fabrication de tubes en acier galvanisé bon marché représente une solution économique pour la production de tubes en fer galvanisé avec précision et efficacité. Ce matériel polyvalent fonctionne à travers un processus systématique qui commence par l'alimentation de bobine et se termine par la production de tubes finis. La machine intègre une technologie de laminage avancée qui garantit un diamètre de tube et une épaisseur de paroi constants tout au long du processus de fabrication. Elle est équipée d'un système de contrôle automatisé qui maintient les paramètres de production, y compris le contrôle de vitesse, la surveillance de la température et les protocoles d'inspection de qualité. L'équipement est conçu pour gérer diverses spécifications de tubes, produisant généralement des tubes allant de 1/2 pouce à 4 pouces de diamètre. Le processus de fabrication comprend plusieurs étapes clés : débobinage, nivellement de bande, usinage des bords, formage, soudage, calibrage et découpe. La construction robuste de la machine assure sa durabilité tout en maintenant une efficacité opérationnelle, avec des vitesses de production pouvant atteindre jusqu'à 30-40 mètres par minute. De plus, elle inclut des caractéristiques de sécurité essentielles telles que des mécanismes d'arrêt d'urgence et des gardes protecteurs. Le design modulaire de la machine permet une maintenance facile et un remplacement rapide des composants, minimisant les temps d'arrêt et prolongeant la durée de vie opérationnelle. Ce matériel est particulièrement adapté aux opérations de fabrication de petite à moyenne envergure, offrant un excellent équilibre entre le coût d'investissement et la capacité de production.