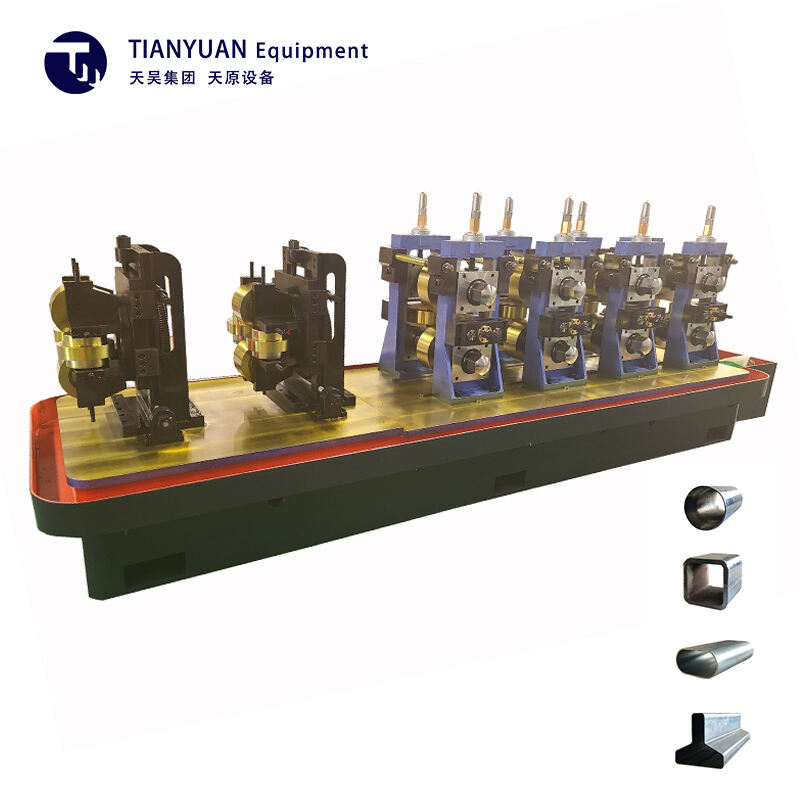

պահանջագրվող խողովակ ձևավորման մաքինա

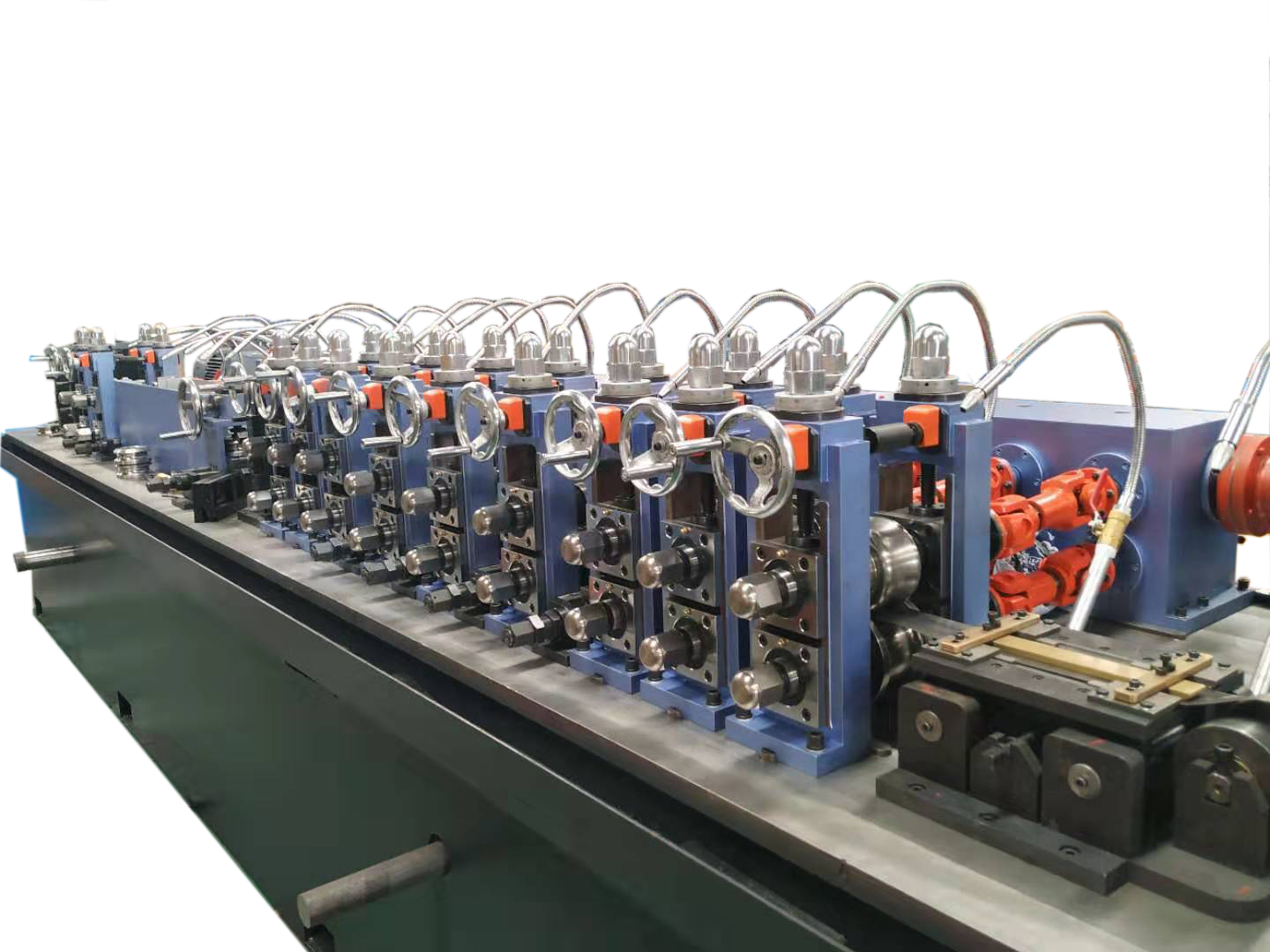

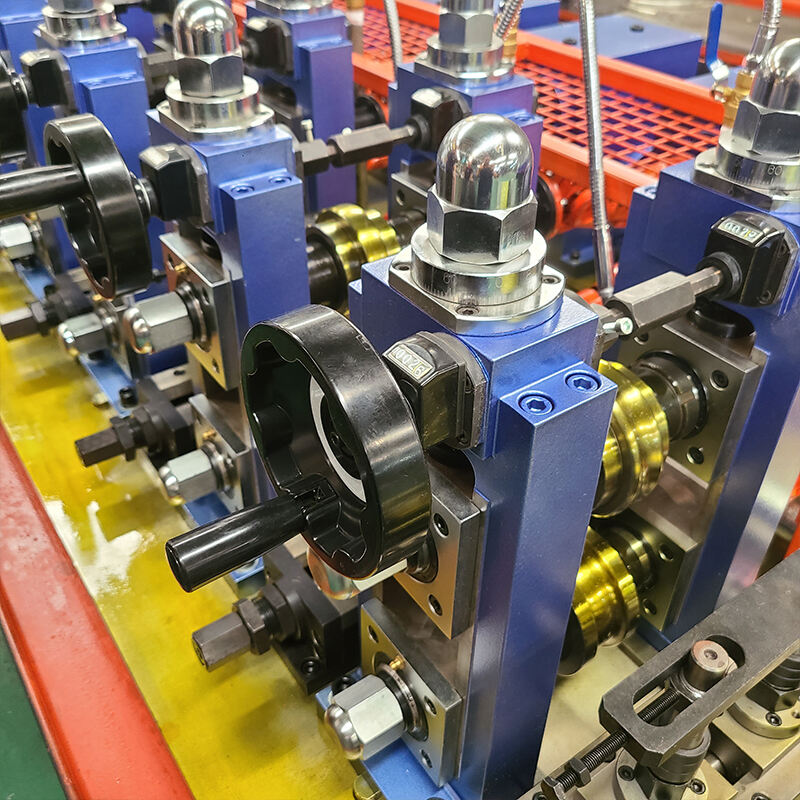

Պարունակելի տուբեր ձևավորման մաքինան ներկայացնում է գործարարության տեխնոլոգիայի հիմնավոր առաջադրամ, առաջարկում չորսանկյուն շերտություն և ճշգրտություն տուբերի գործարարության ժամանակ: Այս նորարար ապարատականը միացնում է ուժող մեխանիկական ինժեներիություն և ավանդական 디จի털 կառավարման համակարգեր՝ տուբեր ստեղծելու համար տարբեր չափերով և նորմատիվներով: Մաքինան ունի կարևորագույն դաշտավորման համակարգ, որը կարող է համաձայնվել փոքր տրամագիծի տուբերից մինչև մեծ գործարարական կանալների ստեղծելու համար: Նրա մոդուլային դիզայնը թույլ է տալիս արագ փոխանցում տարբեր տուբերի պրոֆիլների միջև՝ մնացնելով հաստատուն որակ ամբողջ գործարարության ժամանակ: Այն ներառում է ավանդական կարգավորման համակարգեր, որոնք համոզված չափանիշների ճշգրտություն և մակերևույթի որակ ապահովում են: Գերակայուն ավտոմատացումի հատկությունները թույլ են տալիս անընդհատ գործարարություն նվազագույն օպերատորի միջանկյունում՝ ավելի շատ գործարարություն ապահովելու և նվազեցնելու աշխատավարության արժեքները: Սիստեման ներառում է բազմաթիվ ձևավորման ստացիոնարներ, որոնք անընդհատորեն ձևավորում են նյութը ցանկացած տուբերի կառուցվածքում՝ յուրաքանչյուր ստացիոնար ճշգրտորեն կառավարելով՝ ապահովելու օպտիմալ ձևավորման ճնշում և արագություն: Ապահովության հատկությունները ներառում են կրիտիկական կանգնում մեխանիզմներ, պահպանող պահպանիչներ և ավտոմատացված սխալների հայտնաբերման համակարգեր՝ նյութի գործարարության և ապարատականի վարունգի պարտադիր հաստատությունը: