հեշտ 'RE ներկայացնող գի տուբեր սարքող մաքինա

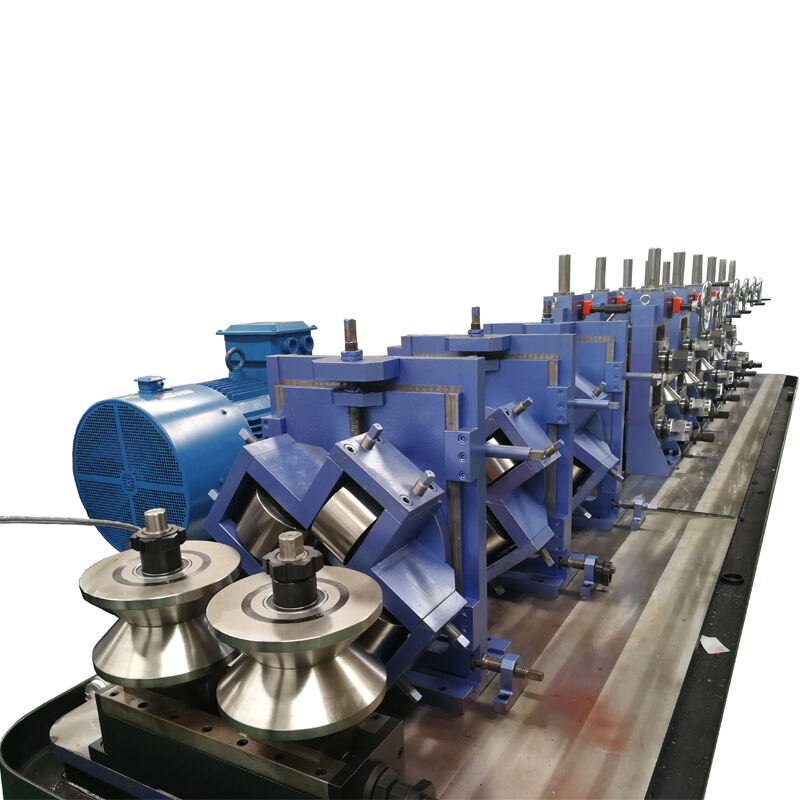

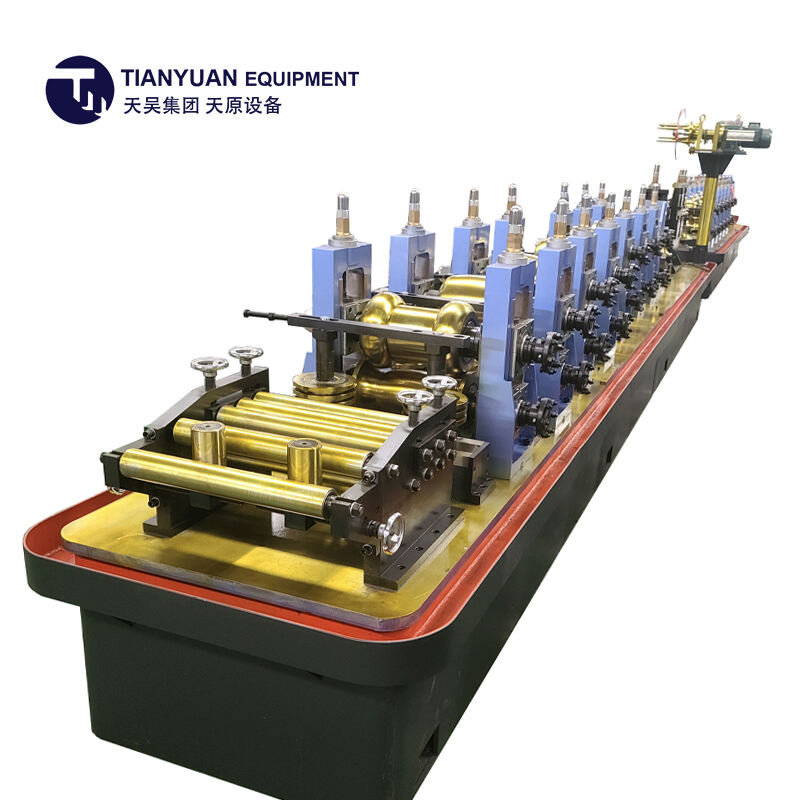

Հեշտ ապահովվող GI կանացի մարդունքի մաքինային սարքը ներկայացնում է կանացի մարդունքի տեխնոլոգիայի կարևոր առաջանորդություն: Այս բարդ սարքը նախատեսված է գալվանացված արկանասնային կանացի արդյունավետ և հաստատուն գործարկում համար: Սարքը ինտեգրում է ստորագրական ձեւավորման տեխնոլոգիան և ավտոմատացված կառավարման համակարգեր, թույլատրելով ճշգրիտ չափականուն ճշգրտություն և գերազանց ավարտի որակ: Այն բաղկացած է ուժեղ համակարգի կառուցվածքից, ավանդական գլանաձևավորման ստացիոններից և օգտագործողների համար հեշտ օգտագործելի կառավարման տախտից, որը թույլատրում է պարամետրերի հեշտ կառավարում: Սարքի ձեւավորման գործընթացը ներառում է միանգամից փուլեր՝ վեցում, հարթության հավասարություն, ձեւավորում, հանգույց, հորին, չափում և ստիրում: Յուրաքանչյուր փուլ օպտիմիզացված է առավելագույն արդյունավետության համար՝ պահպանելով արտադրանքի որակը: Սակայն ներդրված են ավտոմատացված հետևում և حيحումի մեխանիզմներ՝ որոնք համոզված են ուղիղ կանացի արտադրության և հաստատուն դեպի հաստատության համար: Նշանակալի տեխնոլոգիական հատկություններից մեկն է թվային հաստության կառավարումը, ավտոմատացված հանգույցի հետեւումը և իրական ժամանակի որակի ստորագրությունը: Սարքը icularly արժանի է կառուցումների, ինֆրաստրուկտուրայի զարգացման և գործարանային կիրառումների համար, կարողանում է արտադրել կանացի՝ 15մմ-ից մինչև 100մմ տրամագծով: Այն համարվում է ավանդական ՊԼԿ կառավարման համակարգով, որը ապահովում է կայուն գործառունք և ճշգրիտ պարամետրերի կառավարում, արդյունավետության մեջ միջազգային որակի ստանդարտներին համապատասխանող կանացի: