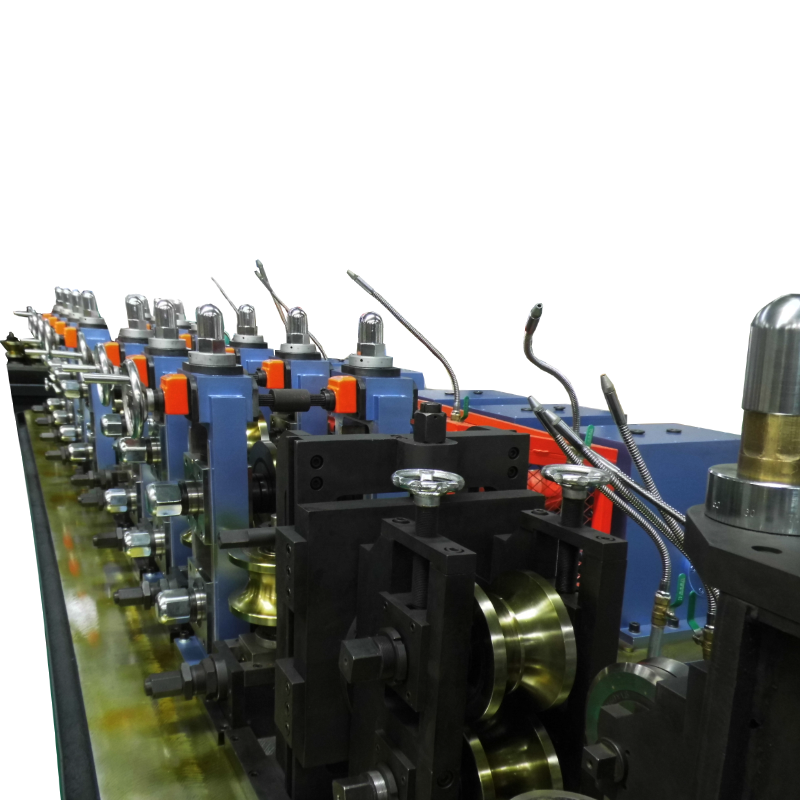

սարք տուբեր պատրաստող մաքինա

Մ․Ս․ տուբային մեքենան ներկայացնում է համեմատագրված պարտադիր գործառուստական համակարգ, որը նախատեսված է լավագույն արդյունքով արտադրել լավանդական metall տուբեր և տուբային համակարգեր։ Այս ավանդական արտադրանքային համակարգը ինտեգրում է բազմաթիվ գործողություններ՝ ներառյալ վեցումը, հարթացումը, ձևավորումը, հանգումը և չափումը միայն մեկ արտադրանքային գործընթացում։ Գործիչը օգտագործում է բարձր հաճախականության հանգումի տեխնոլոգիան, որը հարմարավետորեն և կարողանուն հանգում է ստեղնակետերի համար, իսկ իր ավտոմատացված կառավարման համակարգը պահպանում է հաստատուն որոշակիություն ամբողջ արտադրանքային գործընթացում։ Գործիչը կարող է աշխատել արագությամբ մինչև 120 մետր անգամ րոպե, արտադրելով տուբեր՝ որոնց տրամագիծը փոխվում է 20 մմ-ից 76 մմ-ին և սանդղական հաստություն՝ 0.5 մմ-ից 3 մմ-ին։ Համակարգը ներառում է ավանդական սերվոմոտորներ և PLC կառավարման համակարգ, որոնք թույլ են տալիս ճշգրիտ կարգավորումներ և արտադրանքային պարամետրերի հետ կապված հետևում։ Նրա կարողանուն կառուցվածքը ներառում է կորուստացված ձևավորման գլուխներ և մասնավոր հանգումի համակարգ, որոնք հարմարավետորեն աշխատում են, նույնպես երկար արտադրանքային ցիկլերի ժամանակ։ Գործիչի բազմանալարությունը թույլ է տալիս աշխատել տարբեր արտադրանքային գրադացումներով և նորմատիվներով, ինչպես նաև կառուցական, մебելային արտադրություններից մինչև ավտոմոբայլի և մեխանիկական ինժեներական կիրառություններ։