Ավտոմոբիլային կանացի սարքման մեքենաների դերը ժամանակակից սարքման մեջ

Կանացի սարքման մեքենաների հիմնական ֆունկցիաները ավտոմոբիլային արտադրումում

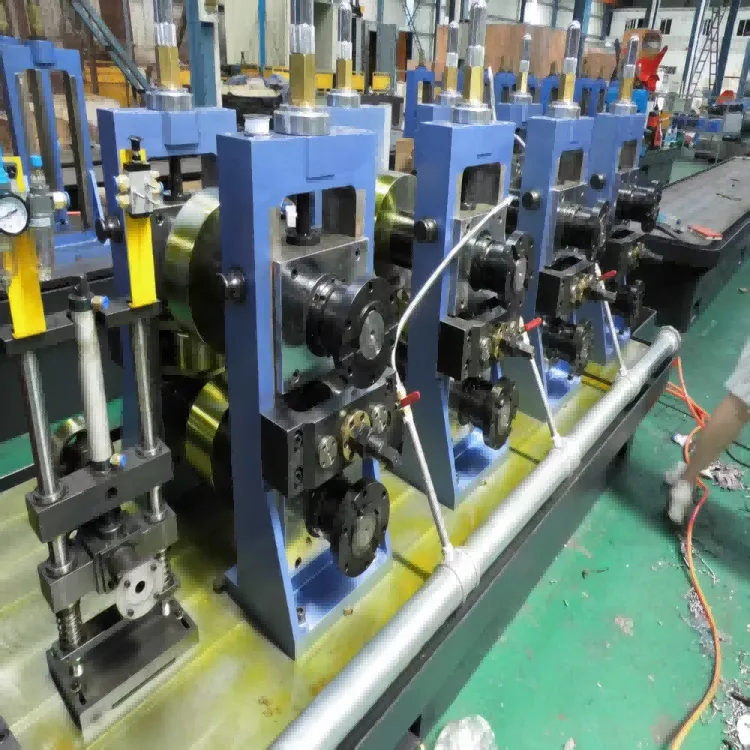

Մեքենաները ավտոմոբիլային խողովակներ պատրաստելու համար կարևոր դեր են խաղում խողովակների մասշտաբային արտադրության գործում՝ ապահովելով ճշգրտություն և արդյունավետություն ամբողջ գործընթացի ընթացքում։ Դրանք կատարում են տարբեր խնդիրներ, ինչպես օրինակ՝ հարթեցնում են միացումները, կատարում ճշգրիտ կտրումներ և ձևավորում ծռումները ճիշտ այնպես, ինչպես անհրաժեշտ է ավտոմոբիլային մասերի համար։ Երբ արտադրամասերը ավտոմատացնում են այդ քայլերը, դա հնարավորություն է տալիս արագացնել արտադրությունը և փոխանց մնալ աշխատանքային ծախսերի կրճատմանը։ Սակայն ամենակարևոր մասը այն է, թե ինչքան համապատասխան որակական է վերջնական արտադրանքը։ Այդ մեքենաները պահպանում են խիստ հանդուրժողականությունը՝ ապահովելով, որ յուրաքանչյուր բաղադրիչ համապատասխանի խիստ չափանիշներին, ինչը անհրաժեշտ է ավտոմեքենաների կառուցման համար, որտեղ անվտանգությունը կախված է տարբեր մասերի միջև հուսալի միացումներից։

Կանացի գործակիցները Ավտոմատացված Pipe Forming Systems-ում

Իրականում ավտոմատացված խողովակաշարերի ձևավորման համակարգերի ճիշտ աշխատելու համար անհրաժեշտ է, որ մի քանի կարևորագույն մասեր աշխատեն միասին: Նկատի ունեցեք խողովակների ծռման սարքերը, կտրիչները և այն հատուկ լցման ամրակները, որոնք ամրացնում են ամեն ինչ արտադրման ընթացքում: Իրական փոփոխությունը տեղի է ունենում CNC համակարգերի նման տեխնոլոգիաների շնորհիվ, որոնք էությամբ վերացնում են ենթադրությունները ամեն մի ծռումը և լցումը ճիշտ տեղում լինելու վերաբերյալ: Եվ մի մոռացեք այդ օրերս ավելացվող բոլոր զգայուն սենսորների և IoT սարքերի մասին: Դրանք թույլ են տալիս օպերատորներին հսկել այդ մեքենաների աշխատանքը իրական ժամանակում: Այս տեսանելիության շնորհիվ կարող են լավ պլանավորված պահպանման աշխատանքներ իրականացվել և անակնկալ կանգերը նվազեցվեն, ինչը բոլորին հայտնի է, որ գործը կանգնեցնելը գումար է կորցնելն է: Ավտոմոբիլաշինական արտադրողները վերջերս ակտիվորեն ընդունել են այդ տեխնոլոգիաները, քանի որ արտադրական գծերի անխափան աշխատանքը առանց նյութերի և ժամանակի փչացման ամենօրյա մրցունակ շուկայում լավ բիզնես մտքի արդյունքն է:

Ավտոմոբայլ Երաժշտության Գործարանների Տուփերի Ֆորմացման Տեխնոլոգիայով

Բարձր Ճշգրտությամբ Տուբերի Ծողեցում Երաժշտային Կոմպոնենտների Համար

Ճշգրիտ խողովակների ծռումը անհրաժեշտ է ավտոմոբիլային արտանետման մասերի արդյունավետ արտադրության համար: Այս տեխնոլոգիայի շնորհիվ արտադրողները կարող են ձևավորել արտանետման խողովակներ, որոնք ճիշտ կերպով կտեղավորվեն ավտոմեքենայի շրջանակներում՝ առանց խնդիրների, այնպես, որ աշխատեն ճիշտ առաջին օրվանից: Շրջադիստ ծռման մեթոդը իրականում մեծացնում է ծռման ճշգրտությունը՝ նվազեցնելով արտադրության ընթացքում ապրանքանյութերի կորուստը: Ուսումնասիրություններ ցույց են տվել, որ երբ գործարանները օգտագործում են այսպիսի ճշգրիտ ծռման տեխնիկաներ, արտանետման համակարգերում խողովակների սխալ տեղակայման պատճառով առաջացած խնդիրները նվազում են մոտ 20%-ով: Երբ յուրաքանչյուր մաս համապատասխանում է խիստ սպեցիֆիկացիաներին, խողովակների հետ աշխատող մեքենաները ավելի լավ արտադրանք են ապահովում և արտանետման համակարգերը ընդհանրապես ավելի երկար են տևում:

Նյութի հաստատություն և դուրսագրումների համաձայնություն

Երբ ավտոմեքենաների արտանետման համակարգեր են ստեղծվում, շատ կարևոր է, թե ինչքան է տևում դրանց կյանքը և թե ինչպես են դրանք համապատասխանում արտանետման կանոններին։ Այսօր խողովակների արտադրման գործում ավելի լավ նյութեր են օգտագործվում, ինչպիսին են՝ բարձր ամրությամբ պողպատը և տարբեր դիմացկուն համաձուլվածքները, քանի որ արտանետման համակարգերը մշտապես են ենթարկվում բարձր ջերմաստիճանի և քիմիական նյութերի։ Այդ ամրակայուն նյութերի օգտագործումը թույլ է տալիս համապատասխանել այդ խիստ արտանետման օրենքներին և ավտոմեքենաների համար ավելի կանաչ տարբերակ ապահովել։ Որոշ հետազոտություններ ցույց են տվել, որ այդ նոր համաձուլվածքների վրա անցնելը իրականում կարող է արտանետման մասերի կյանքը մոտ 30%-ով երկարացնել, ինչը երկար ժամանակ ավելի շատ փող է խնայում և թափոնները նվազեցնում։ Այն ավտոմեքենաների արտադրողները, ովքեր ներդնում են որակյալ նյութերի մեջ, վերջապես ստեղծում են արտանետման համակարգեր, որոնք ավելի լավ են աշխատում ամենօրյա հիմքով և միաժամանակ օգնում են կրճատել աղտոտումը։

MatchConditionական և բրեյկ տուփերի ստեղծում մեքենայի անվտանգության համար

Հիդրոավազի տուփերի ստեղծում բրեյկ համակարգերի համար

Ավտոմեքենաների հիդրավլիկ խողովակների արտադրման եղանակը կարևոր է ապահովելու համար, որ ավտոմեքենաների արգելակման համակարգերը աշխատեն հուսալի և արդյունավետ: Արտադրողները հիմա օգտագործում են սառը ձգման և հիդրաձևավորման նման տեխնիկաներ ամուր, առանց արտահոսքի խողովակներ ստեղծելու համար, որոնք իրականում բարելավում են արգելակների աշխատանքը ճնշման տակ: Ինչո՞ւ է սա կարևոր: Բացահայտվել է, որ արդյունաբերական տվյալները ցույց են տալիս, որ այս նոր արտադրական մոտեցումները կրճատում են արգելակային գծերի անվանական անսարքությունները մոտ 25%-ով: Քանի որ մեծամասնությունը ավտոմեքենաների հիդրավլիկ խողովակների որակի վրա են հիմնված իրենց արգելակման համակարգերի համար, ավելի լավ արտադրությունը անմիջականորեն փոխակերպվում է ավելի անվտանգ վարման փորձի մեջ: Ավտոմոբիլային ոլորտը շարունակում է նորամուծությունների հետ ճշգրիտ այն պատճառով, որ վարորդի անվտանգությունը գերակա է մնում ավտոմեքենաների արտադրության բոլոր մակարդակներում:

Տեխնիկա դիմացող հավասարմություններ հեռավարման գծերում

Շատ կարևոր է ապահովել արտահոսքից պաշտպանված փողոցների ճիշտ էլեկտրական լավ փորագրությունը, երբ ստեղծում են հեղուկի փոխադրման գծեր, որոնք պետք է դիմանան բոլոր տեսակի շրջակա միջավայրի փոփոխություններին: TIG փորագրությունը իր վոլֆրամե էլեկտրոդով և ազնիվ գազի պաշտպանությամբ ապահովում է իրական ճշգրտություն, իսկ MIG փորագրությունը աշխատանքը ավարտում է արագ՝ մետաղե լարի մատուցմամբ: Երկու մեթոդներն էլ ստեղծում են ամուր հանգույցներ ավտոբրոններում, որոնք չեն թողնում հեղուկների արտահոսքը: Արդյունաբերական մասնագետները գնահատում են, որ արհեստանոցները այս ավելի լավ փորագրման մեթոդներին անցնելով հուսալիությունը մեծանում է շուրջ 40%-ով, չնայած իրական արդյունքները կախված են բազմաթիվ գործոններից: Ավտոմեքենաների արտադրողների համար հատկապես կարևոր է այդ փոխադրման գծերը ամուր պահելը, քանի որ նույնիսկ փոքր արտահոսքերը կարող են վատացնել մեքենաների աշխատանքը և վտանգել վարորդների անվտանգությունը: Վերջին տարիներին ավտոմոբիլային արդյունաբերությունը դանդաղ սկսել է ընդունել այս բարելավված փորագրման տեխնոլոգիաները, ինչը հնարավորություն է տալիս կառուցել ավելի հուսալի համակարգեր, որոնք ապահովում են մեքենաների անվտանգ շարժը ճանապարհներով:

Կառուցում մարմնային կոմպոնենտների մեքենայի համար դեմքերի

Կառուցում կարգավորման կանալների համար հարթության դիրքերին

Շասիի խողովակների պատրաստման եղանակը մեքենաների անվտանգությունն ապահովելու գործում կարևոր դեր է խաղում աղետների դեպքում: Ավտոմեքենաների արտադրողները ջանքեր են գործադրում, որպեսզի ապահովեն այդ մասերի հարվածներ դիմադրելու ունակությունը: Նրանք այժմ օգտագործում են ավելի ամուր նյութեր, ինչպես օրինակ՝ բարձր ամրության պողպատը և որոշ նոր կոմպոզիտներ: Բացի այդ, սկսել են կիրառել լազերային էլեկտրակապման և հատուկ սոսնձանյութերի միջոցներ, որպեսզի ամեն ինչ միասին ամրացնեն: Ըստ վերջից արդյունաբերական զեկույցների, ժամանակակից շարժակազմերի փորձարկումները բացահայտել են մոտ 30 տոկոսով ավելի մեծ դիմադրություն, քան այն, ինչ որ նախկինում տեսնում էինք: Եվ սա կարևոր է, քանի որ ավելի ամուր շարժակազմերը նշանակում են, որ բախումների դեպքում մեքենայի ներսում գտնվող մարդիկ ավելի քիչ են վնասվում, ինչը ցկյան բարենպաստ է ավտոմեքենաներով անվանական անվտանգության մասին մտածելը:

Դեղանային ալյումինի ինտեգրացիա համակարգի դիզայնում

Ավտոմեքենաների շրջանակներում թեթև համաձուլվածքների ներմուծումը ցույց է տալիս արտադրողների մտածելակերպի իրական փոփոխությունը՝ ավելի լավ վառելիքի խնայողություն ապահովելու համար անվտանգությունը չուղղահայացելով: Ավտոմեքենաների արտադրողները մեծապես օգտագործում են ալյումինի և այլ վերացարկ պողպատների նման նյութեր, քանի որ դրանք դիմացկուն են, բայց ավելի թեթև են: Արտադրամասերը ստիպված էին ամբողջովին վերանախագծել իրենց մեթոդները, որպեսզի ճիշտ կերպով մշակեն այս նոր նյութերը, ինչը նշանակում է, որ այժմ մենք տեսնում ենք ավտոմեքենաներ, որոնք ճանապարհներում ավելի թեթև են, բայց բավականաչափ ամուր են՝ ուղևորների պաշտպանության համար: Որոշ հետազոտություններ ցույց են տալիս, որ այդպիսի կառուցվածքով ավտոմեքենաները կարող են վառելիքի ծախսերը 15 տոկոսով նվազեցնել: Եվ սա ոչ միայն բյուջեի համար է լավ: Թեթև ավտոմեքենաները ավելի քիչ վառելիք են այրում, ուստի արտանետում են նաև ավելի քիչ աղտոտիչ նյութեր: Սա համապատասխանում է կառավարությունների կողմից տրանսպորտային ոլորտում մաքուր օդ և ածխաթթու գազի արտանետումների նվազեցման վերաբերյալ բոլոր կանոնակարգերին:

Պարունակությունը և նախատեսումը ավտոմոբիլային կանալների արտադրության մեջ

Գերակայությունավոր արտադրություն բազմամոդելային արտադրանքների համար

Այսօրվա ավտոմոբիլային ոլորտում, որտեղ ավտոմեքենաների մոդելները տարբեր ձևերով և չափերով են գալիս, ճկուն արտադրական հնարավորություններ ապահովելը շատ կարևոր է: Այդ ճկուն արտադրական կարգավորումները թույլ են տալիս գործարաններին ճկուն լինել աշխատանքային գործընթացները վերակարգավորելու հնարավորությամբ՝ խուսափելով խոշոր վերակարգավորումների դժվարանքներից, ինչն ամբողջ արտադրությունը ավելի հարթ դարձնում է: Երբ ընկերությունները տեղակայում են այդ ճկուն համակարգերը, նրանք ձեռք են բերում տարբեր բաղադրիչների տեխնիկական բնութագրերի միջև հեշտությամբ անցում կատարելու հնարավորություն, ինչն իրենց տալիս է իրական ճկունություն, երբ արտադրության կարիքները փոխվում են: Որոշ հետազոտություններ ցույց են տվել, որ գործարաններում, որտեղ միաժամանակ աշխատում են մի քանի արտադրական գծեր, արտադրողականությունը մոտ 20 տոկոսով ավելանում է: Շուկայի տատանումներին համապատասխանելուց բացի, այդ ճկունությունը իրականում օգնում է արտադրողներին մնալ հաճախորդների ճաշակների անակնկալ փոփոխություններին առաջինը պատասխանելու դիրքում:

Հաճախակի Պրոտոտիպավորում Customs Vehicle Designs -ի համար

Նոր արագ պրոտոտիպավորման մեթոդների շնորհիվ ավտոմեքենաների արտադրման եղանակը արագ փոխվում է: Երբ ստեղծողները օգտագործում են 3D տպիչներ և համակարգչով ղեկավարվող այդ հիանալի մեքենաները, նրանք կարող են ավելի արագ պատրաստել մասնակի մաղուղներ ավտոմեքենաների համար, քան ավելի վաղ: Այս մասերը ճիշտ համապատասխանում են յուրաքանչյուր ավտոմեքենայի կարիքներին: Քանի որ պրոտոտիպները այժմ ավելի արագ են ստացվում, ընկերությունները ամիսներ չեն սպասում նախագծերի պատրաստ լինելուն: Նրանք միշտ առաջ են գնում, երբ հաճախորդները ցանկանում են մասնակի փոփոխություններ: Որոշ իրական օրինակներ ցույց են տալիս, որ այս մոտեցումը օգտագործող խանութները հաճախ երկու անգամ կամ ավելի շատ կրճատում են իրենց նախագծման ժամանակը: Այս արագությունը նշանակում է, որ ավտոմեքենաների արտադրողները կարող են ավելի արագ ներդնել նոր գաղափարներ և մասնակի կառուցումներ, ինչը նրանց համապատասխան պահում է այն շուկայում, որտեղ բոլորը ցանկանում են մի բան, որը եզակի է անմիջապես:

Տուների ստեղծման մեքանիզմների առաջացումները և ապագա տեսանկարներ

AI-Driven որոշակիության կառավարում Tube Manufacturing-ում

Արհեստական ինտելեկտով աջակցվող որակի վերահսկողության համակարգերը փոխում են արդյունաբերական հատվածում խողովակների արտադրման եղանակը: Այս առաջադեմ համակարգերը հսկում են արտադրությունը իրական ժամանակում, այնպես որ խնդիրները կարող են հայտնաբերվել նրանց խոշոր խնդիրներ դառնալուց առաջ: Դրանց հետևում եղող տեխնոլոգիան ներառում է մեքենայական ուսուցում, որը իրականում սովորում է անցյալի սխալներից՝ կանխելու նման սխալների կրկնությունը ապագայում: Որոշ գործարաններ տեղեկացնում են, որ այդպիսի խելացի համակարգեր տեղադրելուց հետո թերություններով ապրանքների քանակը 40%-ով նվազել է: Ավտոմեքենաների արտադրողների համար, ովքեր պետք է իրենց խողովակներով համապատասխանեն խիստ ստանդարտներին, այս ճշգրտությունը նշանակում է անցնել ստուգումը և խորապես կանխել հետագա հնարավոր թանկարժեք վերադարձումները:

Ստեղծագործական մեթոդներ էկոլոգիական տուբերի պատրաստման համար

Քանի որ կլիմայական փոփոխությունների մասին ահազարտությունները աճում են, խորադիտակների արտադրությունը ավելի հաստատուն դարձնելը շրջակա միջավայրի վնասը նվազեցնելու և նոր խիստ կանոնակարգերին համապատասխանելու համար շատ կարևոր է: Երբ արտադրողները սկսում են օգտագործել վերամշակված նյութեր և ավելացնում են ավելի կանաչ տարբերակներ խորադիտակների արտադրման մեջ, այդ մոտեցումը զգալիորեն նվազեցնում է թափոնները՝ միաժամանակ բարելավելով ընդհանուր հաստատունությունը: Վերջերս իրականացված ուսումնասիրությունների համաձայն՝ ընկերությունները, որոնք անցնում են այդ մեթոդներին, հաճախ տեսնում են իրենց ածխածնի արտանետումների 30 տոկոսանոց նվազում, ինչը ցույց է տալիս մոլորակի պահպանման նկատմամբ իսկական նվիրումը: Այս փոփոխությունը նույնիսկ ավելի շատ նշանակություն է ձեռք բերում այժմ, քանի որ ավտոմոբիլային ոլորտը արագ փոփոխվում է դեպի ավելի կանաչ գործողություններ՝ կանոնների և հաճախորդների պահանջների հետ մեկտեղ, ովքեր ավելի շատ են հետաքրքրված այն բանով, թե ինչ է տեղի ունենում հետնամուտի ետևում: Կանաչ տնտեսագիտությունը այլևս միայն լավ չէ շրջակա միջավայրի համար, այլ նաև գործնական տնտեսական իմաստ է ունենում, քանի որ այդ մոտեցումները ճիշտ համապատասխանում են արտադրության հեռանկարային ուղղություններին հաջորդ տարիներին:

Հաճախ տրամադրվող հարցեր

Ի՞նչ դեր խաղացնում են ավտոմոբայլ կանացիների մարմնավորումները արդյունաբերության մեջ։

Ավտոմոբայլ կանացի սարքող մաքինաները կարևոր են ճանապարհային կանացների մարդկանիշ արտադրության համար՝ ճշգրտությամբ և արդյունավետությամբ։ Նրանք ավտոմատացնում են համացանցում, ստիրում և ծռում գործողությունները, նվազեցնում են աշխատավարձի արժեքը՝ համարելով բարձր որակի ավտոմոբայլ կոմպոնենտներ։

Ինչպես ավտոմատացված կանացի ձևավորման համակարգերը ավելացնում են արտադրությունը?

Այս համակարգերը օգտագործում են CNC տեխնոլոգիա, սենսորներ և IoT սարքեր՝ արդյունավետություն բարձրացնելու և կրճատելու կանգնումները՝ իրարից ավելացնելով ընդհանուր արտադրության արդյունավետությունը։

Հիմանական է ճշգրիտ կանացի ծռումը դուրսգրումների համակարգերի համար?

Ճշգրիտ կանացի ծռումը համոզում է, որ դուրսգրումների կոմպոնենտները անցնում են ավտոմոբիլների դիզայնին՝ նվազեցնելով դուրսգրումների համակարգի սխալները՝ բարձրացնելով ծռումի ճշգրտությունը և նվազեցնելով նյութային կորցնումը։

Ո՞ր նյութեր օգտագործվում են ավտոմոբայլ դուրսգրումների համակարգերում՝ արդյունավետություն բարձրացնելու համար?

Բարձր ուժունությամբ ստենալեսային արծաթ և ավանցական համաձայնություններ օգտագործվում են՝ կանգնումներից անցնելու և դուրսգրումների ստանդարտներին համապատասխանելու համար՝ ներկայացնելով երկար տարիք դուրսգրումների կոմպոնենտներին։

Ինչպես հիդրավլիկական տուբերի մշակման տեխնոլոգիաները նպաստանում են մեքենայի ան전ությանը:

Տեխնոլոգիաների նման ցոլդ դրավինգը և հիդրոձևումը ստեղծում են ուժեղ և ստորացումով հիդրավլիկական տուբեր, որոնք բարձրացնում են բրեյկի արդյունավետությունը, նշանակալիորեն նվազեցնելով բրեյկի գծերի սխալները:

Հիման փոխանցման գծերում ինչու է կարևոր ստորացումով համարձակ տեխնոլոգիաները:

Տեխնոլոգիաների նման TIG և MIG համարձակումը համոզում է բրեյկի գծերի հաստատությունը՝ նվազեցնելով հիման կորուստը, ինչը կարևոր է մեքենայի արդյունավետության և անտենության համար:

Ինչպես ազդում է շասիի ապարատների ստեղծումը մեքենայի համակարգավոր հարցման վրա?

Պարագայում առաջնորդավոր նյութերի և միացման տեխնիկաների, ինչպիսիք են լազերային հաղորդումը, շասիի տուբերի սարքման միջոցով ավելացվում է ուժը, ինչը նำն է բերում 30%-ական աճին դուրսագրման համակարգում:

Ինչ ոգտագործություններ բերում են կlicerության ալյուրները մեքենայի կառուցման մասնավորություններին:

Կlicerության ալյուրների նման ալյումինի և բարձր ուժով արկանի ալյուրները բարձրացնում են կառուցման արդյունավետությունը՝ պահպանելով ուժը, որտեղ մեքենայի կառուցումը հասնում է մինչև 15% ավելի լավ կառուցման տնտեսություն:

Ինչպես առանցքային մշակումը բարձրացնում է մեքենայական տուբերի մատակարարությունը:

Գերական համակարգերը թույլ են տալիս շուտ փոխարինել տարբեր կաղամբների նորմատիվներով, արդյունքում ավելացնելով արդյունավետությունը՝ թույլ տվելով շուտ փոխվել տարբեր մեքենային մոդելների միջև:

Ինչպե՞ս օգտագործվում է արագ մոդելավորումը սեռավոր մեքենայի iếtների նախագծման մեջ:

Տեխնոլոգիաների նման 3D տպագրումը թույլ է տալիս սպասարկել մասնավոր կաղամբների նախագծման արագ արտադրությունը, նվազեցնելով նախագծման ցիկլի ժամանակը մինչև 50%-ով և թույլ տվելով կառուցվածքային պատասխանություն:

Ինչպե՞ս ավելացնում են AI-ի հանգունեցված համակարգերը կաղամբի արտադրությունը:

AI համակարգերը արտադրությունը դիտարկում են իրական ժամանակում, նպատակահարմարորեն և ուղղարկում են հնարավոր սխալները, այսպիսով նվազեցնելով սխալները 40%-ով և համոզեցնելով բարձր ճշգրտություն և հավատալիություն արտադրության մեջ:

Հիմանի ինչու՞ են կարևոր ստեղծագործական մասնագիտությունները կաղամբի արտադրության մեջ:

Ստեղծագործականության առարկաները, ներառյալ վերակիրառությունը և միրգային նյութերի օգտագործումը, նշանավորությով նվազեցնում են կարբոնային հետքը, համաձայնեցնելով արտադրությունը ժամանակակից միրգային ստանդարտների և համարժեքների հետ:

Բովանդակության աղյուսակ

- Ավտոմոբիլային կանացի սարքման մեքենաների դերը ժամանակակից սարքման մեջ

- Ավտոմոբայլ Երաժշտության Գործարանների Տուփերի Ֆորմացման Տեխնոլոգիայով

- MatchConditionական և բրեյկ տուփերի ստեղծում մեքենայի անվտանգության համար

- Կառուցում մարմնային կոմպոնենտների մեքենայի համար դեմքերի

- Պարունակությունը և նախատեսումը ավտոմոբիլային կանալների արտադրության մեջ

- Տուների ստեղծման մեքանիզմների առաջացումները և ապագա տեսանկարներ

-

Հաճախ տրամադրվող հարցեր

- Ի՞նչ դեր խաղացնում են ավտոմոբայլ կանացիների մարմնավորումները արդյունաբերության մեջ։

- Ինչպես ավտոմատացված կանացի ձևավորման համակարգերը ավելացնում են արտադրությունը?

- Հիմանական է ճշգրիտ կանացի ծռումը դուրսգրումների համակարգերի համար?

- Ո՞ր նյութեր օգտագործվում են ավտոմոբայլ դուրսգրումների համակարգերում՝ արդյունավետություն բարձրացնելու համար?

- Ինչպես հիդրավլիկական տուբերի մշակման տեխնոլոգիաները նպաստանում են մեքենայի ան전ությանը:

- Հիման փոխանցման գծերում ինչու է կարևոր ստորացումով համարձակ տեխնոլոգիաները:

- Ինչպես ազդում է շասիի ապարատների ստեղծումը մեքենայի համակարգավոր հարցման վրա?

- Ինչ ոգտագործություններ բերում են կlicerության ալյուրները մեքենայի կառուցման մասնավորություններին:

- Ինչպես առանցքային մշակումը բարձրացնում է մեքենայական տուբերի մատակարարությունը:

- Ինչպե՞ս օգտագործվում է արագ մոդելավորումը սեռավոր մեքենայի iếtների նախագծման մեջ:

- Ինչպե՞ս ավելացնում են AI-ի հանգունեցված համակարգերը կաղամբի արտադրությունը:

- Հիմանի ինչու՞ են կարևոր ստեղծագործական մասնագիտությունները կաղամբի արտադրության մեջ: