Ավտոմոբիլային կանացի սարքող մաքինա՝ կորի կոմպոնենտներ և աշխատանք

Նորարար կանացի սարքող մաքինայի անհրաժեշտ կոմպոնենտներ

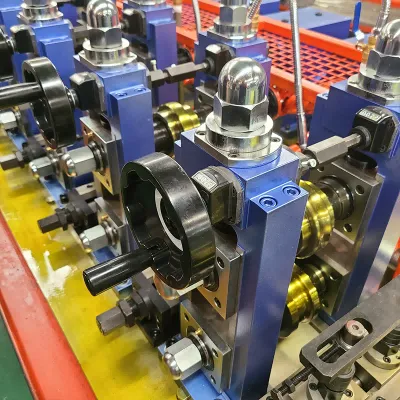

Այսօր խողովակների արտադրման սարքերը բաղկացած են մի քանի հիմնարար մասերից, որոնք աշխատում են միասին, որպեսզի ամբողջ գործընթացը արդյունավետ լինի: Շատ դեպքերում սկզբում լինում է մատանիների բացող սարք, որը վերցնում է մետաղե մատանիները և դանդաղ ու հավասար տալիս դեպի մեքենան: Հետո գալիս է ձևավորման հատվածը, որտեղ հարթ թիթեղներից ստանում են շրջանաձև խողովակներ: Հաջորդը լինում է միացման կայանը, որտեղ հաճախ օգտագործում են բարձր հաճախականությամբ միացման տեխնիկա, որպեսզի խողովակների եզրերը միանան այնպես, որ ճնշման տակ չկորցնեն մաքրությունը: Վերջում գալիս է արագ սառեցման համակարգը, որն ապահովում է ջերմաստիճանի արագ իջեցումը, որպեսզի խողովակները չճկվեն և պահպանեն իրենց չափերը: Եթե այդ մասերից որևէ մեկը չաշխատի ճիշտ, ապա արտադրողները դժվարանալու են խողովակներ արտադրել համապատասխան որակով և չափերով, այդ իսկ պատճառով ամեն մի մաս շատ կարևոր է գործնական կիրառման համար:

Ծրագրավորված համակարգերը խորապես կարևոր են դարձել խորացված ճշգրտության ու արտադրողականության համար խողովակաշին սարքավորումների ոլորտում: Այսօրվա դրությամբ CNC, այսինքն՝ համակարգչային թվային ղեկավարման տեխնոլոգիան ապահովում է, որ բոլոր չափումները ճիշտ համընկնեն նախօրոք սահմանվածի հետ, առանց աշխատողների կողմից մեծ թվով ձեռքով կատարվող աշխատանքների կիրառման, այդպիսով սխալների քանակը և թափոն նյութերը նվազում են: Օրինակ՝ լավ CNC կարգավորումները ավտոմատ կերպով կարող են ճշգրտել անվալարի լարման ցուցանիշները, ինչպես նաև հարմարեցնել լիցքավորման գլխի արագությունը՝ կախված մետաղի տեսակից, որի հետ աշխատում են տվյալ պահին: Այդպիսի ավտոմատացված հնարավորությունները ապահովում են անխափան արտադրությունը, այդ իսկ պատճառով էլ շատ գործարաններ տարբեր ոլորտներից շարունակում են ներդրումներ կատարել իրենց սարքավորումների արդիականացման գործում՝ այդ տեսակի խելացի տեխնոլոգիաների միջոցով:

Վերջին տեխնոլոգիական նվաճումները խորապես փոխում են խողովակների արտադրության արագությունը՝ նվազեցնելով նյութերի թափոնները բոլոր ոլորտներում: Նոր նյութերի համակցումը ավելի լավ նախագծված սարքավորումների հետ նշանակում է, որ այսօրվա խողովակահանող մեքենաները գերազանցում են հին սարքերին: Գործարանները զեկուցում են, որ այժմ ստանում են ավելի շատ արտադրանք իրենց մեքենաներից՝ օգտագործելով մեծապես քիչ հումք, ինչը, իհարկե, օգնում է ավելացնել շահույթը: Դիտեք, թե ինչ է տեղի ունենում լազերային կապանների տեխնիկայի հետ, որոնք կրճատում են թերությունները, և այն խելացի հսկման համակարգերի հետ, որոնք հայտնաբերում են խնդիրները առաջ քան դրանք մեծ խնդիրներ դառնան: Այս տեսակի բարելավումները ոչ միայն փոքր բարելավումներ են, այլ իրական խաղի փոփոխություններ արտադրողների համար, ովքեր փորձում են մնալ մրցունակ դժվարին շուկաներում:

Հիմնական աշխատանքային հասցե. Սpirալից սկսած մինչև ավարտական տուն

Պողպատե փաթիլներից խողովակներ պատրաստելը իրականում բավականին բարդ գործընթաց է՝ մի քանի կարևոր քայլերով: Նախ, փաթիլների հարթեցումը շատ հաճախ հարթ է ընթանում, սակայն օպերատորները պետք է հսկեն ցանկացած ճկումներ կամ ծռումներ, որոնք կարող են առաջանալ այս փուլում: Հարթեցումից հետո մենք կտրում ենք նյութը հատուկ երկարություններով՝ կախված այն բանից, թե ինչ է պետք արտադրության համար: Հետո գալիս է ձևավորման բաժինը, որտեղ մետաղը սկսում է ընդունել խողովակի ծանոթ ձևը՝ ճշգրիտ չափերով: Խողովակների միացումը հնարավոր է ամենակարևոր մասն է: Մենք սովորաբար ընտրում ենք կարապ միացման տեխնիկան, քանի որ դա ավելի ամուր միացումներ է ապահովում խողովակների հատվածների միջև: Վերջապես, կա սառեցման գործընթացը, որը ամեն ինչ տեղում է դնում: Ջերմաստիճանի արագ անկումը ոչ միայն ապահովում է կարի ամրությունը, այլև վերջնական խողովակին տալիս է վերջնական ձևն ու ամրության բնութագիրը:

Որակի վերահսկումը խողովակների արտադրման ընթացքում տեղի է ունենում ամեն մի քայլի դեպքում՝ ապրանքները արդյունաբերության սպասումներին համապատասխան դարձնելու համար: Վերցրեք, օրինակ, ձևավորումը՝ ամենաշատը խողովակները հատուկ չափումների են ենթարկվում և տրվում են հատուկ փորձարկումների, որոնք չեն վնասում դրանք, սակայն հայտնաբերում են խափանումներ, ինչպես օրինակ՝ ճաքեր կամ անհամասեռություններ: Այն վերաբերյալ հարցում, երբ խոսքը շեղակների մասին է, աշխատողները շատ ուշադիր են հսկում այդ մասը, քանի որ վատ շեղակները նշանակում են թույլ կապեր ապագայում: Այս խիստ որակի միջոցառումների կապված մնալը օգնում է ընկերություններին արտադրել խողովակներ, որոնք ավելի երկար են ծառայում և ավելի լավ են աշխատում տարբեր աշխատանքներում, որտեղ անվտանգությունը ամենակարևորն է: Բազմաթիվ գործարաններ հաստատել են, որ այս կանոնակարգերի հետևելը ոչ միայն հաճախորդների բավարարում է ապահովում, այլև իրականում փող է խնայում ժամանակի ընթացքում՝ դաշտում անարդյունավետությունները կրճատելով:

Մեքենաշինական տեխնոլոգիաների վերջին զարգացումները մեծ ազդեցություն են թողնում այն բանի վրա, թե ինչքան արագ են արտադրվում խողովակները և ընդհանրապես ինչքան արդյունավետ են աշխատում գործարանները: Արդյունաբերական տվյալները ցույց են տալիս, որ այն արհեստանոցները, որտեղ կիրառվում են այս նոր համակարգերը, հաղորդում են շարունակական փոխարկումների միջև ավելի քիչ դադարների մասին, արտադրության ընթացքում ավելի քիչ նյութեր են թափոնի ենթարկվում և ընդհանրապես ավելի արագ են ապրանքներն արտադրամատյաններով տեղափոխվում: Խողովակներ արտադրողների համար, ովքեր փորձում են համապատասխանել հաճախորդների ցանկություններին այն պահին, երբ այդ ցանկություններն առաջանում են, սա նշանակում է պատվերներն ավելի արագ կատարել արտադրության ծախսերը չթանկացնելով: Շուկաների արագ զարգացման հետ մրցակիցներից առաջ մնալը դարձել է ավելի քան երբևէ կարևոր:

كيف يشكل الانحناء الدوراني أنابيب السيارات

Դիեի կառուցվածքը ճշգրիտ կորումի համար

Ճշգրիտ արդյունքներ ստանալը շրջանաձև ծռման դեպքում կախված է այն մատրիցների տեսակից, որոնց հետ աշխատում ենք, և դրանց կարգավորումից: Այստեղ կան մի քանի տեսակներ՝ ձևավորող մատրիցներ, որոնք որոշում են վերջնական ձևը, ինչպես նաև ճնշման և սրբիչ մատրիցներ, որոնք վերահսկում են նյութի շարժումը գործընթացի ընթացքում: Այս մասնագիտացված գործիքները օգնում են խուսափել ավելորդ դեֆորմացիաներից ավտոմոբիլային խողովակների ձևավորման ժամանակ: Երբ արտադրողները սխալ են մատրիցների նախագծման մեջ, սկսվում են խնդիրները՝ նյութում ավելորդ լարվածությունների առաջացումը կամ անցանկալի մակերեսային աղավաղումների առաջացումը: Մետաղամշակման արհեստանոցները հաստատել են, որ ավելի լավ մատրիցների ներդրումը բերում է մեծ օգուտի: Ստացվում են ոչ միայն մաքուր և ճշգրիտ ձևեր, այլ նաև ավելի արագ և հարթ արտադրություն: Ավտոմոբիլային արդյունաբերությունը տեսնում է այս մոտեցման իրական առավելությունները՝ ավելի քիչ թափոն մետաղ և մասեր, որոնք համապատասխանում են խիստ չափական հարցերին:

Մանդրելի դերը տուտելիքի ամբողջության պահպանման ժամանակ

Մանդրելները շատ կարևոր են խողովակները ամբողջական պահելու համար, երբ դրանք ծռվում են, հատկապես ավտոմեքենաներում և տրակտորներում: Երբ խողովակը ծռվում է առանց ճիշտ ներքին աջակցության, այն թուլանում է և առաջանում են տարբեր խնդիրներ, ինչպես օրինակ՝ պատերի ճաքերը կամ դրա ձևի փոփոխությունը՝ լինելով օվալաձև փոխարեն շրջանաձևի: Այդ իսկ պատճառով արտադրողները հենվում են տարբեր տեսակի մանդրելների վրա: Փակ տիպի մանդրելները լավ են փոքր խողովակների համար, իսկ գնդաձև մանդրելները ավելի լավ են մեծ խողովակների համար: Կարևոր է նաև նյութը, քանի որ պողպատը ավելի տարբեր ձևով է արձագանքում ծռման գործողություններին համեմատած ալյումինի հետ: Ըստ խոշոր ավտոմոբիլային մատակարարների զեկուցումների, մանդրելների ներդրումը գործընթացում ապահովում է այդ մետաղյա խողովակների ավելի երկար կյանք և ավելի լավ արդյունքներ լարված պայմաններում: Ներկայումս տեսնում ենք ավելի բարդ ծռման դիզայններ, քանի որ ժամանակակից մեքենաները ավելի խիտ տարածքներ են օգտագործում բաղադրիչների համար: Ճիշտ մանդրելի կարգավորումը շատ կարևոր է, եթե ցանկանում ենք, որ մեր արտանետման համակարգերը կամ վառելիքի գծերը հազարավոր մղոններ անցնեն առանց անսպասելի խափանումների:

Ինդուկցիոն ծագում տեխնոլոգիան ավտոմոբայլ մարդատարումում

Տաքացում բարդ կորերի համար

Ինդուկցիոն ծռումը արտադրողներին իրական առավելություն է տալիս ավտոմոբիլային խողովակաշարերի համար անհրաժեշտ բարդ կորեր ստեղծելիս՝ միջոցառումների միջոցով, որոնք բավականին բարդ տաքացման տեխնիկա են օգտագործում: Այս մոտեցման շնորհիվ աշխատողները կարող են ճշգրիտ վերահսկել ջերմաստիճանը ամբողջ ծռման գործընթացի ընթացքում, այնպես որ մետաղը պահպանում է իր ամրությունը ձևավորման ընթացքում: Ջերմությունը հավասարաչափ է բաշխվում խողովակի ամբողջ երկարությամբ, ինչը թույլ է տալիս աշխատանքայիններին ստեղծել տարբեր բարդ ձևեր՝ նյութի ամրությունը չթուլացնելով: Այն արտադրամասերը, որոնք անցել են ինդուկցիոն ծռման, հաճախ նկատում են արտադրության ժամանակի կտրուկ նվազում և ծախսերի իջում, քանի որ նյութի ավելցուկը նվազում է: Այդ ոլորտի խոշոր ընկերությունները ցույց են տվել, թե որքան լավ են ստացվում այս տաքացված ծռումները համեմատաբար ավանդական մեթոդների հետ, մերժված պատվերների քանակի կտրուկ նվազմամբ և ընդհանուր առմամբ ցածր շահագործման ծախսերով:

Ջերմացման համակարգեր նյութերի պահպանման համար

Երբ ինդուկցիոն ճկումը ավարտված է, պատշաճ սառեցումը շատ կարեւոր է դառնում ավտոմոբիլային խողովակների ամրության եւ արտաքին տեսքի համար: Ներկայումս արտադրողները սովորաբար օգտագործում են սառեցման տարբեր մեթոդներ. ոմանք պարզապես թույլ են տալիս սառեցնել դրանք օդում, իսկ մյուսները ջուր են ցողում անմիջապես տաք մետաղի մակերեսների վրա: Հիմնական նպատակն է աստիճանաբար իջեցնել ջերմաստիճանը, որպեսզի չլինեն ներքին լարվածություններ, որոնք կարող են ճեղքել ավելի ուշ, երբ խողովակները գործարկվեն: Այս ջերմաստիճանի կարգավորումը ճիշտ է, եւ դա մեծ տարբերություն է այն հարցում, թե որքան ժամանակ կպահպանվեն այդ բաղադրիչները մինչեւ փոխարինման անհրաժեշտությունը: Մենք տեսել ենք իրական կյանքի ապացույցներ արտադրական գծերից, որտեղ ավելի լավ սառեցման պրակտիկաները նվազեցրել են ձախողումները մոտ 30%-ով, ինչը նշանակում է ավելի քիչ գլխացավեր գործարանի ղեկավարների համար, որոնք պետք է գործեն անսպասելի խափանումների հետ հավաքման ընթացքում:

CNC Կառավարման Համակարգեր Նորարար Աղետների Fabrication-ում

프로그րամային Պարամետրեր Ավտոմոբայլ Ենթադրությունների համար

CNC-ի կառավարման համակարգերը մեծ դեր են խաղում այսօրվա խողովակների արտադրման գործում, հատկապես ավտոմոբիլային արդյունաբերության մեջ: Այդ համակարգերի միջոցով օպերատորները կարող են կարգավորել կարևոր պարամետրեր, ինչպիսիք են կտրման արագությունը, մատերիալի մղման արագությունը և ընդհանուր ցիկլի տևողությունը, որոնք օգնում են ճշգրտել արտադրման գործընթացը: CNC մեքենաների կողմից ապահովվող ճշգրտության շնորհիվ խողովակները ստացվում են համապարփակ որակական, ինչը շատ կարևոր է ավտոմեքենայի մասերի արտադրությունում, որտեղ նույնիսկ փոքրագույն շեղումները կարևոր են: Ավելի քիչ անհրաժեշտություն կա մշտական ձեռքով ճշգրտելու համար, ինչը դարձնում է ամբողջ գործընթացը ավելի կրկնելի, օգնելով արտադրամասերին համապատասխանել խիստ արդյունաբերական պահանջներին՝ առանց հատուկ ջանքերի: Ըստ արդյունաբերական զեկույցների, արտադրամասերը, որոնք անցել են CNC համակարգերի, սովորականից զգալիորեն ավելի ցածր սխալման մակարդակի են հասել համեմատած հին արտադրման մեթոդների հետ: Ավելի քիչ սխալներ նշանակում են փոքր թափոններ և ավելի լավ արտադրանքի համապարփակություն խմբերով, ինչը տալիս է արտադրողներին առավելություն մրցունակ ավտոմասների շուկայում:

Սխալների ուղղումն արագացող մեխանիզմներ

Ժամանակակից CNC կառավարման համակարգերը հագեցած են բավականին տպավորիչ սխալների ուղղման հատկություններով, որոնք մեծ տարբերություն են ստեղծում խողովակների արտադրության մեջ: Նրանք մշտապես վերահսկում են գործընթացը իրական ժամանակի մոնիտորինգի եւ հետադարձ կապի մեխանիզմների միջոցով, հայտնաբերելով խնդիրները, երբ դրանք տեղի ունեն, որպեսզի տեղում կարողանան կատարել փոփոխություններ: Պահպանելով հետեւողականությունը խմբաքանակների միջեւ եւ նվազեցնելով նյութերի վատնումը, հենց այդ պատճառով են այս համակարգերը այդքան կարեւոր: Երբ սխալները ինքնաբերաբար ուղղվում են, այլ ոչ թե սպասում են, որ ինչ-որ մեկը ուշ նկատի ունենա դրանք, գործարանները խնայում են հումքի վրա ծախսերը եւ իրենց մեքենաները ավելի երկար են աշխատում, երբ դրանք կանգ են առնում: Արդյունաբերության տվյալները ցույց են տալիս, որ արտադրողները, ովքեր ընդունում են CNC համակարգերը, սովորաբար մեծապես նվազեցնում են ծախսերը ժամանակի ընթացքում: Ավելի քիչ փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փայտե փ

Պահուսիական ապահովում մեքենայական տուփերի արտադրանքում

Դեstrukտիվ չունեցող տեստավորման մեթոդներ

Ոչ քայքայող փորձարկումը (NDT) ավտոմոբիլային խողովակների հուսալիությունն ստուգելու համար անհրաժեշտ է դարձել։ Ավտոմոբիլային արդյունաբերությունը մի քանի տարբեր մոտեցումներ է օգտագործում, ինչպես օրինակ՝ ուլտրաձայնային փորձարկումներ և ռենտգենյան պատկերավորումը, որպեսզի գնահատի խողովակների որակը՝ առանց դրանք վնասելու ստուգման ընթացքում։ Սա շատ կարևոր է, քանի որ այդ փորձարկումները կարող են հայտնաբերել ինչպես մետաղյա պատերի ներսի, այնպես էլ դրսի խնդիրներ, որոնք այլապես աննկատ կմնային։ Արտադրողական մեծամասնակի ցուցումները հիմա ներառում են NDT գործընթացների համար խիստ պահանջներ, ինչը իմաստ ունի, երբ մտածում ենք այն մասին, թե ինչ է տեղի ունենում, երբ խողովակները ձախողվում են ճանապարհին։ Իրական տվյալները ցույց են տալիս, որ ըմբռնումները, որոնք հետևում են խորամանկ NDT մեթոդներին, սովորաբար խողովակների ձախողումների հետ կապված խնդիրների շատ ավելի քիչ դեպքեր են ապրում։ Ավտոմեքենաներ արտադրողների համար, ովքեր առանձնահատուկ ուշադրություն են դարձնում բաղադրիչների անվտանգությանը, այս տեսակի փորձարկումները ոչ միայն ցուցադրված են, այլ գործնականում պարտադիր են։

Տոլերանսի ստանդարտները մեքենայի ինտեգրացիայի համար

Ավտոմոբիլային խողովակների արտադրության մեջ թույլատրելի շեղումների ստանդարտների հետևում շատ կարևոր է, քանի որ հակառակ դեպքում դրանք ճիշտ չեն տեղադրվի ավտոմեքենաներում: Ստանդարտները արտադրողներին ճիշտ չափերն են ցույց տալիս և թույլատրելի շեղումների սահմանները նշում յուրաքանչյուր չափում: Առանց այդ խողովակները կարող է ճիշտ չհամընկնեն ավտոմեքենայի համակարգի մյուս մասերի հետ: Բնօրինակ սարքավորումների արտադրողների տեխնիկական պահանջները իրոք պահանջում են այդ ստանդարտների կատարում, քանի որ վատ որակի խողովակները կարող են խաթարել ավտոմեքենայի աշխատանքը: Որոշ հետազոտություններ ցույց են տվել, որ ընկերությունները, որոնք խիստ հետևում են այդ ճշգրիտ չափերին, ավելի երկար և ավելի լավ են աշխատում: Շատ ավտոմեքենաների արտադրողներ այդ մասին տեղյակ են և իրենց խողովակների արտադրությունը պահում են այդ սահմաններում, նույնիսկ եթե դա երբեմն մի փոքր ավելի թանկ է արժենում: Իհարկե, ոչ ոք չի ցանկանում վերադարձնել կամ ստանալ սխալ տեղադրման մասին բողոքներ:

Ավտոմոբայլ տուփերի մշակման համար նյութերի ընտրություն

Մեծ ուժով արկան vs ալյումինի հարաբերություններ

Ճիշտ նյութերի ընտրությունը ավտոմոբիլային խողովակների արտադրության համար ներառում է բարձր ամրությամբ պողպատի և ալյումինե համաձուլվածքների առավելությունների և թերությունների հաշվարկումը: Պողպատը շարունակում է մնալ արտադրողների համար նախընտրելի տարբերակ, քանի որ այն դիմակայում է լարմանը և պահում է արտադրության ծախսերը ցածր, որը հատկապես կարևոր է այն մասերի համար, որոնց անհրաժեշտ է առավելագույն կոնստրուկտիվ ամրություն: Ալյումինը այլ պատկերացում է տալիս: Նրա թեթև քաշը օգնում է ավտոմեքենաներին ավելի լավ աշխատել և արտանետել ավելի քիչ աղտոտող նյութեր, ինչը ավտոմոբիլային արդյունաբերության մեջ ամենօրյա խնդիր է դարձել նոր արտանետման ստանդարտների շնորհիվ, որոնք ամբողջ աշխարհում կիրառվում են: Իհարկե ալյումինի դեպքում կա մի թերություն՝ այն ավելի թանկ է, քան պողպատը: Արդյունաբերական փորձարկումները ցույց են տվել, որ ալյումինե խողովակներով պատրաստված մեքենաները սովորաբար վառելիքի 5-8%-ով ավելի քիչ են օգտագործում իրենց պողպատե համապատասխանների համեմատ՝ անվտանգության և ընդհանուր անվտանգության ցուցանիշները չվնասելով: Շատ արտադրամասեր իրենց ընտրությունը կատարում են հաշվի առնելով իրենց նախագծի պահանջները, բյուջեի սահմանափակումները և երկարաժամկետ նորոգման հարցերը:

Կոռոզիոն դիմադրության պահանջներ

Կոռոզիայի դիմադրելու ունակությունը մնում է ավտոմոբիլային խողովակաշարերի նկատմամբ ամենակարևոր պահանջներից մեկը, հատկապես այն տարածաշրջաններում, որտեղ ավտոմեքենաները ձմռան ամիսներին ճանապարհային աղի ազդեցության տակ են կամ ափամերձ տարածքներում, որտեղ աղի ջրի վնասների ենթակենք են: Արտադրողները իրենց խողովակները մանրամասն գնահատման են ենթարկում նրանց տեղադրումից առաջ, հաճախ ենթարկելով աղային ցանցաշերտի խցիկների, որոնք միմյանց հաջորդող տարիների ամբիոնտ լարվածությունը նկարագրում են ընդամենը մի քանի օրվա ընթացքում: Պաշտպանողական միջոցառումները տատանվում են տաք խորասուզման ցինկապատման տեխնիկայով կիրառվող ավանդական պատվածքներից մինչև նոր բազմաթիվ բարիերային շերտեր ստեղծող պոլիմերային բուժումներ: Ուսումնասիրությունները ցույց են տվել, որ ճիշտ մշակված խողովակները ծառայում են ավելի երկար ժամանակ, մինչդեռ պահպանում են իրենց մեխանիկական ամրության հատկությունները չմշակված նմանատիպերի համեմատ: Ավտոմոբիլային ճարտարագետների համար, ովքեր աշխատում են ավտոմեքենաների նախագծման սպեցիֆիկացիաների վրա, այս կոնկրետ հարցի ճիշտ լուծումը պարզապես արդյունաբերական կանոնակարգերին համապատասխանելու մասին չէ, այլ ազդում է ավտոմեքենայի երկարաժամկետ հուսալիության և հաճախորդի բավարարվածության վրա ճանապարհին:

Օդանավի համակարգերում կիրառումներ

Ելական համակարգի ստեղծում

Ավտոմոբիլային արտանետման համակարգերի ստեղծումը պահանջում է ուշադիր աշխատանքի և դիմացկուն նյութերի համադրություն, որոնք կարողանում են դիմանալ նրանց վրա դրված պայմաններին: Շատ արհեստանոցներ խողովակների ձևավորումից են սկսում, այնուհետև կատարում են դրանց լուծում, իսկ հետո ավելացնում են ավարտիչ շերտեր, որոնք պաշտպանում են ջերմային վնասումների և ժամանակի ընթացքում ժանգից պաշտպանելու համար: Նյութեր ընտրելիս աչքի են ընկնում չժանգոտվող պողպատը, քանի որ այն ավելի լավ է դիմանում բացարձակ ջերմաստիճաններին, քան մյուս մետաղները, և ավելի երկար է ծառայում արտանետման միջավայրում: Ավտոմեքենաների արտադրողները նաև ստեղծագործաբար են մոտենում հարցին. մտածեք սպորտային ավտոմեքենաների կրկնակի խողովակների կառուցվածքի մասին: Դրանք ակնհայտորեն լավ տեսք ունեն, սակայն իրականում օգնում են շարժիչներին ավելի արդյունավետ աշխատել, ինչը նշանակում է ավելի մաքուր արտանետում և երբեմն նույնիսկ վառելիքի ավելի լավ տնտեսություն: Այս բոլոր բարելավումները միայն տեսքի մասին չեն էլ այնքան: Արտադրողները նաև ստիպված են լինում հետևել խիստ արտանետման ստանդարտներին, այնպես որ ամեն փոքր փոփոխություն կարևոր է, երբ փորձում են ստեղծել այնպիսի տրանսպորտային միջոցներ, որոնք ամբողջությամբ համապատասխանում են օրինական սահմանաչափերին և միևնույն ժամանակ լավ են աշխատում:

Տուելի գործարկման տեխնոլոգիա

Ճիշտ աշխատանք է պահանջվում վառելիքի մատակարարման խողովակներ պատրաստելիս, քանի որ գործ ունենք բարձրակարգ բռնկվող նյութերի հետ: Հիմնական քայլերն ընդգրկում են հատուկ էլեկտրակապանքային տեխնիկա, առանց կարանց խողովակներ ստեղծելը և բավականաչափ փորձարկումներ կատարելը ստուգելու համար ամեն ինչ ճիշտ է ամրացված: Կանոնների հետևելը SAE-ի նման կազմակերպություններից ոչ միայն ցանկալի է, այլ անհրաժեշտ է այդ մասերի անընդհատ աշխատանքի համար ամենակրիտիկական պահերին: Որոշ իրական օրինակներ ցույց են տալիս, թե ինչ է տեղի ունենում, երբ արտադրողները սկսում են օգտագործել լազերային մետաղակտիչ մեքենաներ և ռոբոտներ էլեկտրակապանքի համար: Այդ բարելավված մեթոդները արտադրում են վառելիքի մատակարարման ավելի լավ աշխատող և ավելի քիչ վտանգավոր համակարգեր: Ինքնաշխատ արդյունաբերության մեջ տեղի ունեցած զարգացումներն ըմբռնեցնում են, թե ինչու է շարունակական բարելավումները արտադրողական գործընթացներում այնքան կարևոր և՛ վարորդի անվտանգության, և՛ մեքենայի աշխատանքի համար:

Հաճախ տրամադրվող հարցեր

Ի՞նչ են ավտոմոբայլի տուփերի արտադրանքի մաքինայի հիմնական կոմպոնենտները։

Ավտոմոբայլ կանացի սարքման մեքենան կազմված է հիմնական բաղադրիչներից, ինչպիսիք են՝ վերանշումը, ձևավորման բաժները, հանգույցի միավորը և հոթորոշումների համակարգը: Յուրաքանչյուրը խաղացում է կարևոր դեր բարձր որակի կանացի սարքման գործընթացում:

Ինչպես օգտագործվում է CNC տեխնոլոգիան կանացի սարքման համար:

CNC տեխնոլոգիան թույլ է տալիս ճշգրիտ կառավարում սարքման պարամետրերի վրա, նվազեցնելով սխալները և բարձրացնելով կանացի սարքման ընդհանուր արդյունավետությունը և որակը:

Որ նյութեր են հաճախ օգտագործվում ավտոմոբայլ կանացի սարքման համար:

Հաճախ օգտագործվող նյութերն են՝ բարձր ուժունությամբ արկային և ալյումինի համադրությունները, որոնք յուրահատուկ առավելություններ են տալիս՝ ինչպիսիք են՝ կարողություն կամ կիրառություն դառնալու համար ավելի բարձր կառուցվածքային ուժունություն կամ կիրառություն դառնալու համար ավելի փոքր կշիռ՝ ավելի լավ կառուցվածքային բարձրացման համար:

Ինչու՞ է կարևոր անկորոցնական տեստավորումը ավտոմոբայլ կանացի սարքման մեջ:

Անկորոցնական տեստավորումը համոզվում է ավտոմոբայլ կանացի ամբողջության և ան전ացման մասին՝ հայտնի անտառումներ առաջացնելուց առանց՝ արտադրանքին նույնիսկ ոչ մի վանդակություն չարտադրելու դեպքում:

Ինչպես է կորոզիայի համակարգելիությունը ազդում ավտոմոբայլ կանացիների վրա:

Կորոզիայի հետագծությունը կարևոր է մեքենայական տուբերի երկար տևումը և վստահելիությունը guarantee ելույթով, 특히 խաղաղ շրջադատության պայմաններում։

Բովանդակության աղյուսակ

- Ավտոմոբիլային կանացի սարքող մաքինա՝ կորի կոմպոնենտներ և աշխատանք

- كيف يشكل الانحناء الدوراني أنابيب السيارات

- Ինդուկցիոն ծագում տեխնոլոգիան ավտոմոբայլ մարդատարումում

- CNC Կառավարման Համակարգեր Նորարար Աղետների Fabrication-ում

- Պահուսիական ապահովում մեքենայական տուփերի արտադրանքում

- Ավտոմոբայլ տուփերի մշակման համար նյութերի ընտրություն

- Օդանավի համակարգերում կիրառումներ

-

Հաճախ տրամադրվող հարցեր

- Ի՞նչ են ավտոմոբայլի տուփերի արտադրանքի մաքինայի հիմնական կոմպոնենտները։

- Ինչպես օգտագործվում է CNC տեխնոլոգիան կանացի սարքման համար:

- Որ նյութեր են հաճախ օգտագործվում ավտոմոբայլ կանացի սարքման համար:

- Ինչու՞ է կարևոր անկորոցնական տեստավորումը ավտոմոբայլ կանացի սարքման մեջ:

- Ինչպես է կորոզիայի համակարգելիությունը ազդում ավտոմոբայլ կանացիների վրա: