Մետաղի արտադրության բուռն զարգացումը առաջատար արտադրական տեխնոլոգիաների շնորհիվ

Արդյունաբերական հարթակը փորձել է նշանակալի փոփոխություններ՝ MS խողովակների արտադրման սարքերի ներդրմամբ արտադրական գործընթացներում։ Այս բարդ սարքավորումները դարձել են ժամանակակից մետաղակազմության հիմքը՝ թույլ տալով արտադրողներին հասնել աննախադեպ արտադրողականության և ճշգրտության մակարդակի։ Խողովակների ձևավորման բարդ գործընթացի ավտոմատացմամբ այս սարքերը վերանշել են արտադրության ստանդարտները բազմաթիվ արդյունաբերություններում։

Հիմնարար բաղադրիչներ և Գործողությունների արդյունավետություն

Անհրաժեշտ մեքենայական տարրեր

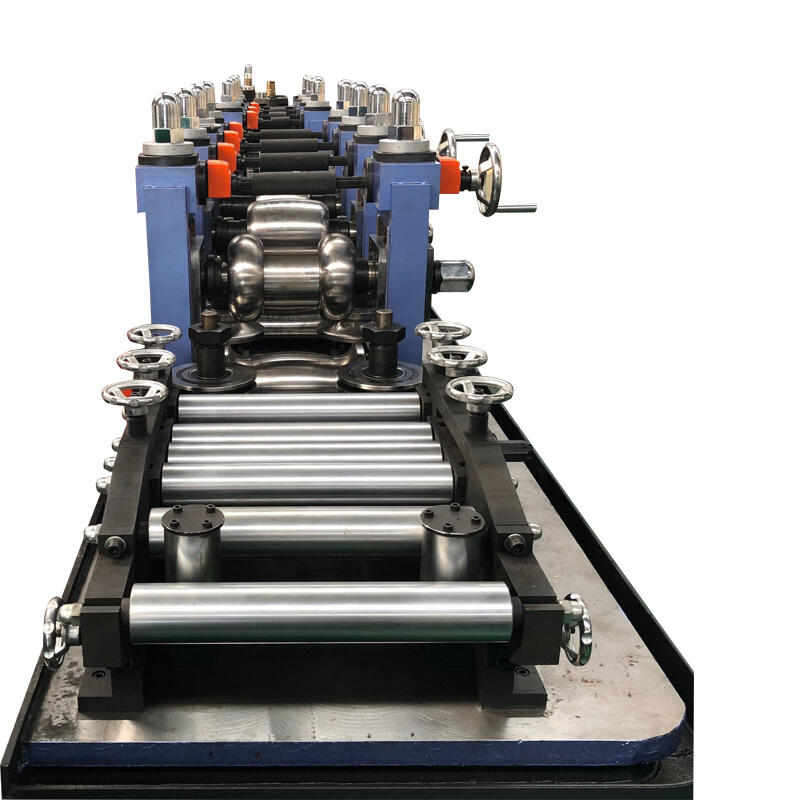

MS խողովակների արտադրման յուրաքանչյուր սարքի հիմքում ընկած է ճշգրիտ ինժեներական մշակված բաղադրիչների շարք, որոնք աշխատում են կատարյալ համատեղելիությամբ: Նյութի մատակարարման համակարգը նյութը հաստատուն կերպով մատակարարում է ձևավորման հատված՝ սկսելով գործընթացը: Շարք ձևավորող կայաններ աստիճանաբար ձևավորում են մետաղական շերտը՝ ստանալով ցանկալի խողովակաձև կառուցվածքը, իսկ լցոնման միավորը ապահովում է կառուցվածքային ամբողջականությունը՝ օգտագործելով բարձր հաճախականությամբ լցման տեխնոլոգիան: Այնուհետև չափի կարգավորման հատվածը ճշգրտում է չափսերը՝ համապատասխանեցնելով ճշգրիտ ստանդարտներին:

Կտրման միավորը, որը սարքավորված է առաջադեմ դանակի տեխնոլոգիայով, ապահովում է մաքուր և ճշգրիտ կտրվածքներ նախապես որոշված երկարություններով: Որակի վերահսկման սենսորները անընդհատ հսկում են ամբողջ գործընթացը՝ իրական ժամանակում կատարելով կարգավորումներ՝ արտադրության ստանդարտները պահպանելու համար: Բաղադրիչների այս բարդ համահնչությունը ապահովում է առավելագույն արդյունավետություն և նյութի նվազագույն թափոններ:

Առաջադեմ կառավարման համակարգեր

Ժամանակակից MS խողովակներ ստեղծող մեքենաները ներառում են բարդ կառավարման համակարգեր, որոնք թույլ են տալիս օպերատորներին աննախադեպ ճշգրտությամբ կառավարել արտադրության յուրաքանչյուր ասպեկտ: Շոշափելի էկրանների միջոցով իրական ժամանակում հսկվում են կարևորագույն պարամետրերը, իսկ ավտոմատ կարգավորման մեխանիզմները երկարատև արտադրության ընթացքում ապահովում են հաստատուն որակ: PLC համակարգերի ինտեգրումը թույլ է տալիս արագ անցում տարբեր խողովակների սպեցիֆիկացիաների միջև՝ զգալիորեն կրճատելով կանգնելու ժամանակը:

Այս կառավարման համակարգերը նաև հնարավորություն են տալիս կանխարգելի սպասարկման ծրագրավորում, հսկում են էներգասպառումը և ստեղծում մանրամասն արտադրության զեկույցներ: Մի քանի արտադրական պրոֆիլների պահպանման հնարավորությունը թույլ է տալիս արագ կարգավորում կրկնվող պատվերների համար՝ բարձրացնելով ընդհանուր գործողությունների արդյունավետությունը:

Արտադրության օպտիմալացման ռազմավարություններ

Արագության և արդյունավետության բարելավումներ

MS խողովակների արտադրման սարքավորման արտադրողականությունը առավելագույնի հասցնելու համար անհրաժեշտ է արտադրության օպտիմալացման համար լավ մշակված մոտեցում: Արագ փոխարինվող գործիքավորման համակարգերի ներդրումը հնարավորություն է տալիս արագ անցում կատարել տարբեր խողովակների չափերի և կոնֆիգուրացիաների միջև: ձևավորող ռոլիկների պարբեշտ կալիբրացումը երաշխավորում է արտադրանքի համազանգվածությունը՝ պահպանելով օպտիմալ արտադրական արագությունը: Ընդհանրացված հակակոռոզիոն համակարգերը նվազեցնում են կարևորագույն մասերի մաշվածությունը, երկարաձգելով սարքավորումների կյանքը և նվազագույնի հասցնելով սպասարկման դադարները:

Վերլուծելով արտադրական տվյալները՝ արտադրողները կարող են նույնականացնել կապուղիները և իրականացնել թիրախային բարելավումներ: Սա կարող է ներառել որոշակի մասերի թարմացում, նյութերի տեղափոխման ընթադարձությունների կատարելագործում կամ շահագործման պարամետրերի ճշգրտում՝ գագաթնակետային արդյունավետություն հասնելու համար:

Որակի վերահսկողության ինտեգրում

MS խողովակների սարքավորումներում ներդրված ժամանակակից որակի վերահսկման համակարգերը օգտագործում են լազերային չափման տեխնոլոգիա և փոխադարձ հոսանքի փորձարկում՝ ապահովելու չափագրական ճշգրտությունը և կառուցվածքային թերությունների իրական ժամանակում հայտնաբերումը: Այս համակարգերը ավտոմատ կերպով կարգավորում են արտադրության պարամետրերը՝ պահպանելով որակի ստանդարտները միաժամանակ առավելացնելով արտադրողականությունը: Վիճակագրական գործընթացի վերահսկման մեթոդների ներդրումը թույլ է տալիս օպերատորներին նախապես հայտնաբերել և լուծել հնարավոր որակի խնդիրները, մինչև դրանք ազդեն արտադրության վրա:

Չափման համակարգերի պարբերական կալիբրացումը և փորձարկման սարքավորումների ճիշտ սպասարկումը ապահովում են արտադրության ընթացքում վստահելի որակի վերահսկում: Որակի այս գործող կանխարգելման մոտեցումը զգալիորեն կրճատում է թափոններն ու վերամշակումը, նպաստելով ընդհանուր արտադրողականության բարելավմանը:

Նյութերի տեղափոխում և աշխատանքային գործընթացի օպտիմալացում

ՈՒղղակի նյութերի կառավարում

Արդյունավետ նյութի կառավարումը սկսվում է հումքի ճիշտ պահեստավորմամբ և պատրաստմամբ: Ավտոմատացված կերակրման համակարգերի ներդրումը ապահովում է նյութի անընդհատ հոսքը MS խողովակի արտադրման մեքենային, իսկ փաթաթանի կեղծ սարքավորումները կանխում են վնասվածքները և կրճատում են կարգավորման ժամանակը: Նյութերի պահեստավորման հատվածների ռազմավարական տեղադրումը և նյութերի հոսքի օրինաչափությունների զգուշալի պլանավորումը նվազեցնում են կեղծման ժամանակը և վնասվածքների ռիսկը:

Գագաթնակետային պաշարների կառավարման համակարգերը օգնում են պահպանել պաշարների օպտիմալ մակարդակը՝ ապահովելով անհրաժեշտ նյութերի առկայությունը նախատեսված արտադրության ընթացքում: Նյութերի կառավարման այս համակարգային մոտեցումը զգալիորեն նպաստում է ընդհանուր շահագործման արդյունավետությանը:

Վերջնական արտադրանքի կառավարում

Վերջնական խողովակների ճիշտ մշակումը կարևոր է ապրանքի որակի պահպանման և թրուփթ-ը առավելագույնի հասցնելու համար: Ավտոմատացված կույտավորման և փաթաթման համակարգերը ապահովում են վերջնական արտադրանքի արդյունավետ մշակում՝ նվազագույնի հասցնելով վնասվածքի ռիսկը: Պահեստավորման ճիշտ լուծումների և նյութերի մշակման սարքավորումների կիրառումը հեշտացնում է վերջնական արտադրանքի հարթ տեղափոխումը հաջորդ մշակման փուլեր կամ առաքման գոտիներ:

Որակի վերահսկողության կայանների ռազմավարական տեղադրումը և պահեստային տարածքների ճիշտ կազմակերպումը օպտիմալացնում են աշխատանքային ընթացքը և նվազեցնում են մշակման ժամանակը: Վերջնական արտադրանքի այս համակարգային մոտեցումը ապահովում է նյութերի արդյունավետ տեղափոխումը՝ պահպանելով արտադրանքի որակը:

Տեխնիկական սպասարկում և աշխատանքի ցուցանիշների հսկում

Պրոֆիլակտիկ fontStyle-ի protocols

Կանոնավոր սպասարկումը անհրաժեշտ է MS խողովակների արտադրման սարքավորման օպտիմալ աշխատանքը պահպանելու համար: Ամբողջական սպասարկման գրաֆիկների իրականացումը, որն ընդգրկում է ամենօրյա ստուգումներ, պարբերական կարգավորումներ և պլանային մասերի փոխարինումներ, օգնում է կանխել անսպասելի դադարները: Սպասարկման գործողությունների ճիշտ փաստաթղթավորումն ու սպասարկման անձնակազմի կանոնավոր վերապատրաստումը ապահովում են սարքավորումների համապարփակ խնամք:

Ռազմավարական հսկման համակարգերը օգնում են նախապես նույնականացնել հնարավոր խնդիրները՝ մինչև դրանք լուրջ խնդիրներ առաջացնեն, ինչը թույլ է տալիս պլանավորված սպասարկման միջամտություններ իրականացնել և նվազագույնի հասցնել արտադրության խաթարումները: Սպասարկման այս ռազմավարական մոտեցումը զգալիորեն երկարաձգում է սարքավորումների կյանքը՝ պահպանելով առավելագույն արդյունավետությունը:

Արդյունքի անալիտիկա

Ժամանակակից MS խողովակներ ստեղծող մեքենաները արտադրում են մեծ ծավալով շահագործման տվյալներ, որոնք կարող են վերլուծվել արդյունավետությունը բարելավելու համար: Արտադրության հսկման համակարգերի ներդրումը տալիս է արժեքավոր տեղեկություններ սարքավորումների արդյունավետության, նյութերի օգտագործման և որակի մասին: Այս տվյալների պարբերական վերլուծությունը օգնում է նույնականացնել միտումներն ու բարելավման հնարավորությունները՝ հնարավոր դարձնելով տվյալների հիման վրա որոշումներ կայացնելը:

Կատարողականի հսկման համակարգերի ինտեգրումը ձեռնարկության կառավարման ծրագրաշարի հետ հնարավոր է դարձնում համապարփակ արտադրական պլանավորում և ռեսուրսների հատկացում: Այս վերլուծական մոտեցումը կատարողականի կառավարման մեջ աջակցում է անընդհատ բարելավման նախաձեռնություններին և օգնում պահպանել մրցակցային առավելությունը:

Հաճախ տրվող հարցեր

Ո՞ր գործոններն են ազդում MS խողովակներ ստեղծող մեքենայի արտադրողականության վրա:

Արտադրության արագությունը կախված է մի շարք գործոններից, ներառյալ նյութի հատկությունները, խողովակի չափսերը, աշխատանքային պայմանները և սարքավորման հնարավորությունները: Օպտիմալ արագության կարգավորումները կախված են ճիշտ լարվածքի որակի և չափանիշների ճշգրտությունից՝ հաշվի առնելով նյութի հաստությունը և ձևավորման պահանջները:

Որքան հաճախ պետք է սպասարկվի MS խողովակի սարքը:

Սովորաբար պարբեշտ սպասարկման գրաֆիկը ներառում է օրական ստուգումներ, շաբաթական կարգավորումներ և ամսական հիմնական ստուգումներ: Կոնկրետ սպասարկման ընդմիջումները կախված են արտադրության ծավալից, շահագործման պայմաններից և արտադրողի խորհուրդներից: Կանխարգելիչ սպասարկումը պետք է իրականացվի սարքավորման փաստաթղթերին և օգտագործման օրինաչափություններին համապատասխան:

Ի՞նչ որակի վերահսկողության միջոցառումներ են անհրաժեշտ օպտիմալ արտադրության համար:

Կարևորագույն որակի վերահսկման միջոցառումներից են չափագրական ստուգումը, լցակավորման որակի փորձարկումը, մակերեւույթի եզրափակման գնահատականը և կառուցվածքային ամբողջականության հաստատումը: Ավտոմատացված ստուգման համակարգերի ներդրումը, չափման սարքավորումների պարբերական կալիբրացումը և որակի պարամետրերի ճիշտ փաստաթղթավորումը ապահովում են արտադրանքի հաստատուն որակ:

Բովանդակության աղյուսակ

- Մետաղի արտադրության բուռն զարգացումը առաջատար արտադրական տեխնոլոգիաների շնորհիվ

- Հիմնարար բաղադրիչներ և Գործողությունների արդյունավետություն

- Արտադրության օպտիմալացման ռազմավարություններ

- Նյութերի տեղափոխում և աշխատանքային գործընթացի օպտիմալացում

- Տեխնիկական սպասարկում և աշխատանքի ցուցանիշների հսկում

- Հաճախ տրվող հարցեր