Ժամանակակից պողպատե խողովակների արտադրության տեխնոլոգիայի հասկացությունը

Արտադրող արդյունաբերությունը պողպատե կառուցվածքների տեխնոլոգիայում տեսել է նշանակալի առաջընթաց, որի առաջատարներից մեկը MS խողովակ ստեղծող մեքենան է: Այս բարդ մեքենաները հեղափոխել են արտադրողների կողմից պողպատե խողովակների արտադրման ձևը՝ առաջարկելով աննախադեպ ճշգրտություն, արդյունավետություն և բազմաֆունկցիոնություն: Անկախ նրանից՝ արդյոք դուք փոքր չափի արտադրող եք, թե խոշոր արդյունաբերական կազմակերպություն եք կառավարում, MS խողովակ ստեղծող մեքենայի հնարավորությունների և առավելությունների հասկանալը կարևոր է տնտեսական ներդրումների համար ճիշտ որոշումներ կայացնելու համար:

Մոդեռն MS խողովակների արտադրման սարքերի համատեղում են առաջատար տեխնոլոգիաները և հզոր ինժեներական սկզբունքները՝ ապահովելով հաստատուն, բարձրորակ արտադրանք: Այս սարքավորումները կարող են հարթ պողպատե շերտերը վերածել կատարյալ ձևավորված խողովակների՝ համակարգված ձևավորման, լցումային եւ վերջնական մշակման գործընթացների միջոցով: Այս տեխնոլոգիան ավելի հասանելի է դառնում բոլոր չափերի ձեռնարկությունների համար, ինչը այն դարձնում է հարմար ընտրություն արտադրության հնարավորությունները ընդլայնելու և արտադրության արդյունավետությունը բարձրացնելու համար:

Կարևորագույն բաղադրիչներ և շահագործման հատկանիշներ

Հիմնական մեխանիկական համակարգեր

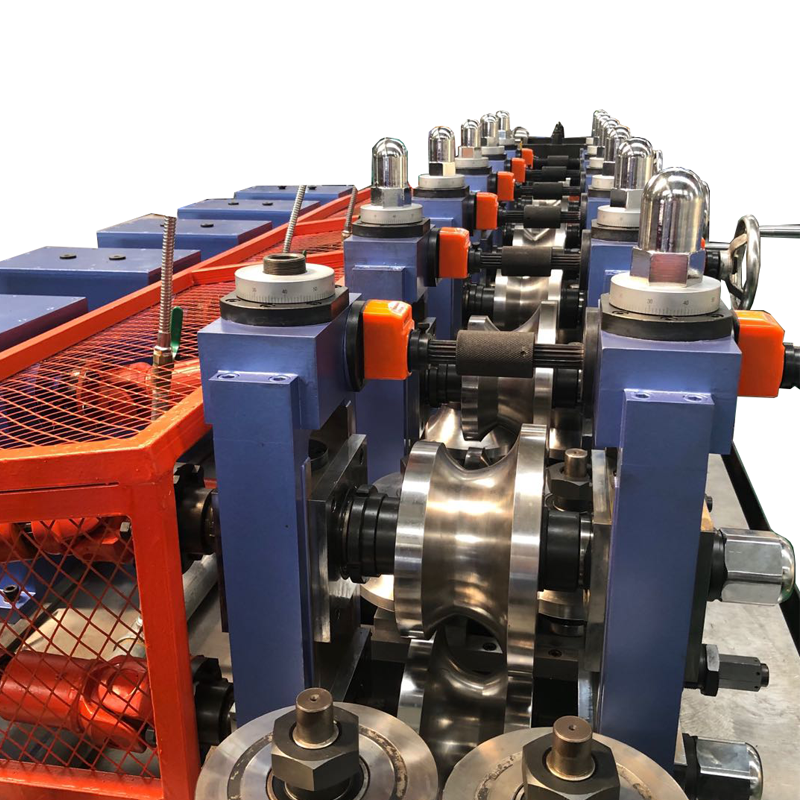

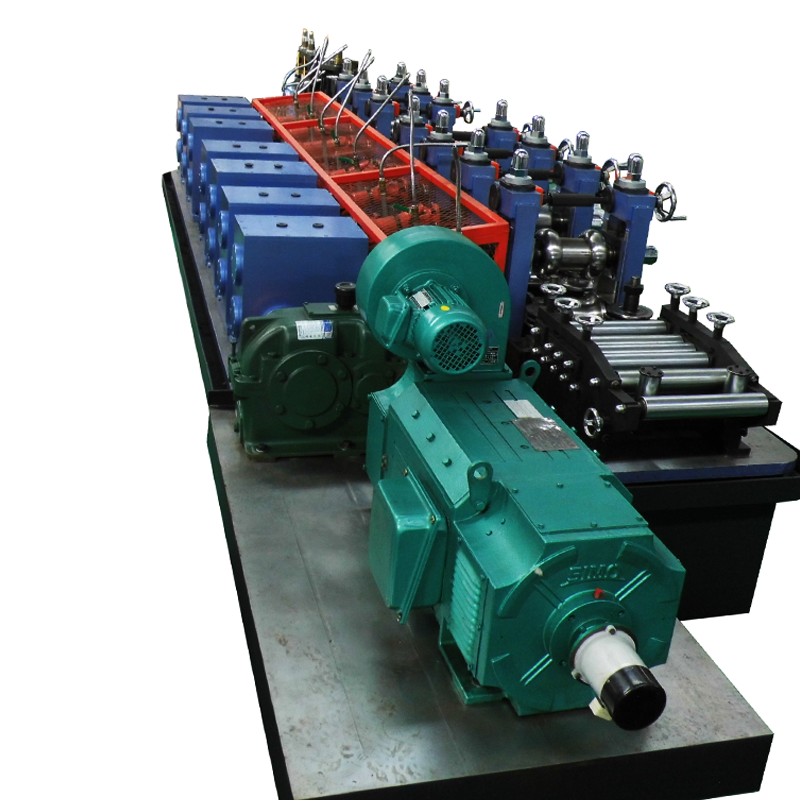

MS խողովակներ ստեղծող մեքենայի սրտում գտնվում են ճշգրիտ կերպով ստեղծված մեխանիկական բաղադրիչները: Ձևավորման հատվածը բաղկացած է մի քանի ռոլիկներից, որոնք աստիճանաբար ձևավորում են պողպատե շերտը՝ դարձնելով այն խողովականման: Յուրաքանչյուր ռոլիկ հատուկ ձևով է կարգավորված՝ համազանգված ճնշման բաշխում և ճշգրիտ չափադիր վերահսկողություն ապահովելու համար: Շերտի մատուցման մեխանիզմը, որը հագեցած է արդյունավետ լարման համակարգերով, ապահովում է նյութի համազանգված հոսքը արտադրության ընթացքում:

Լցակավորման կայանը ներառում է արդյունավետ և հուսալի կապեր ստեղծելու նորագույն տեխնոլոգիաներ: Ժամանակակից մեքենաները, որպես կանոն, օժտված են բարձր հաճախականությամբ լցակավորման համակարգերով, որոնք առանց ավելցուկային ջերմության մուտքի՝ ապահովում են մաքուր և արդյունավետ լցակավորում: Սա արդյունքում տալիս է ավելի բարձր միացման ամրություն և նվազագույն դեֆորմացիա վերջնական արտադրանքում:

Կառավարման և ավտոմատացման հնարավորություններ

Ժամանակակից MS խողովակների արտադրման սարքավորումներն օժտված են բարդ կառավարման համակարգերով, որոնք թույլ են տալիս ճշգրիտ կերպով կարգավորել և հսկել պարամետրերը: Թվային ինտերֆեյսները թույլ են տալիս օպերատորներին ճշգրտել արտադրության գործընթացի տարբեր ասպեկտներ, սկսած մատուցման արագությունից մինչև լցման պարամետրերը: Ինքնաշխատ որակի վերահսկման համակարգերը անընդհատ հսկում են խողովակների չափերը և լցման ամբողջականությունը՝ ապահովելով արտադրանքի հաստատուն որակ:

Ավանդական մոդելները ներառում են ծրագրավորվող տրամաբանական կառավարիչներ (PLC), որոնք կարող են պահել բազմաթիվ արտադրության բաղադրություններ, թույլ տալով արագ փոխարկում տարբեր խողովակների սպեցիֆիկացիաների միջև: Այս ճկունությունը մեքենան դարձնում է հարմարեցված տարբեր արտադրական պահանջներին և հաճախորդների պահանջներին:

Արտադրողական հնարավորություններ և կիրառումներ

Չափի տիրույթ և նյութի համատեղելիություն

MS խողովակների պատրաստման մեքենաները առաջարկում են հիանալի բազմաֆունկցիոնություն՝ խողովակների չափսերի և նյութի հատկորոշումների տեսանկյունից: Ժամանակակից համակարգերը սովորաբար կարողանում են մշակել 12 մմ-ից մինչև 76 մմ և ավելի տրամագծով խողովակներ՝ պատերի հաստությամբ 0,5 մմ-ից մինչև 3 մմ: Այս ճկունությունը թույլ է տալիս արտադրողներին սպասարկել շուկայի տարբեր հատվածներ՝ սկսած մебլերի արտադրությունից մինչև կառուցվածքային կիրառություններ:

Այս մեքենաները հիանալի են մշակում նոսր պողպատը, սակայն շատ մոդելներ կարողանում են նաև մշակել չժանգոտվող պողպատի և այլ համաձուլվածքների տարբեր սորտեր: Տարբեր նյութերի հետ աշխատելու կարողությունը հնարավորություններ է բացում հատուկ արդյունաբերություններում՝ ինչպես օրինակ ավտոմոբիլային մասերի և արդյունաբերական սարքավորումների արտադրությունը:

Արտադրության արդյունավետություն և ելքի որակ

MS խողովակների սարքի ամենահամոզիչ առավելություններից մեկը դրա արտադրության արդյունավետությունն է: Առաջադեմ մոդելները կարող են հասնել մինչև 50 մետր րոպեկան արագության, ինչը թույլ է տալիս արտադրել մեծ ծավալներ օրական: Անընդհատ արտադրության հնարավորությունը՝ համակցված նվազագույն սկզբնական կարգավորումների հետ, համեմատաբար զգալիորեն բարձր արտադրողականություն է ապահովում ավանդական արտադրական մեթոդների համեմատ:

Որակի հաստատունությունը նույնպես ժամանակակից խողովակների սարքերի հիմնական առանձնահատկությունն է: Ինտեգրված որակի վերահսկման համակարգերը, ներառյալ լազերային չափման սարքերն ու աուլտրաձայնային փորձարկման սարքավորումները, ապահովում են, որ յուրաքանչյուր խողովակ համապատասխանի նշված չափանիշներին և կառուցվածքային պահանջներին: Այս հուսալիությունը նվազեցնում է թափոններն ու վերամշակումը՝ նպաստելով ընդհանուր գործողությունների արդյունավետությանը:

Տնտեսական դիտարկումներ և ROI անալիզ

Նախնական ներդրում և շահագործման ծախսեր

MS խողովակների սարքավորում ներդրում կատարելը պահանջում է զգուշավոր ֆինանսական պլանավորում: Նախնական կապիտալ ծախսերը ներառում են ոչ միայն սարքավորման արժեքը, այլ նաև տեղադրման ծախսերը, օպերատորների վերապատրաստումը և հնարավոր շենքի փոփոխությունները: Սակայն ժամանակակից սարքավորումները նախատեսված են էներգաարդյունավետության և նվազագույն սպասարկման պահանջների համար, որը օգնում է փոխհատուցել շահագործման ծախսերը:

Շահագործման ծախսերը սովորաբար ներառում են էլեկտրաէներգիայի սպառումը, հումքի ծախսերը և պարբերական սպասարկումը: Շատ արտադրողներ նկատում են, որ աշխատանքի նվազագույն պահանջարկը և արտադրության արդյունավետության բարձրացումը հանգեցնում է միավորի արժեքի ներգործող ցուցանիշների, հատկապես՝ մեծ ծավալով գործողությունների դեպքում:

Երկարաժամկետ ֆինանսական օգուտներ

MS խողովակների սարքավորման երկարաժամկետ տնտեսական առավելությունները տարածվում են անմիջական արտադրական ծախսերից դուրս: Խիստ որակի վերահսկողություն սահմանելու կարողությունը նվազեցնում է նյութի թափոններն ու հաճախորդների վերադարձված ապրանքները: Բացի այդ, հնարավորությունն արտադրելու հատուկ պահանջներով արտադրանքներ թույլ է տալիս արտադրողներին գներ սահմանել ավելի բարձր մակարդակով՝ հատուկ արտադրանքների համար:

Շուկայի նկատմամբ արձագանքման արագությունը ևս մեկ կարևոր առավելություն է: Արտադրության պարամետրերի արագ ճշգրտումն ու տարբեր խողովակների չափերի արտադրումը հնարավորություն են տալիս արտադրողներին արագ արձագանքել շուկայի պահանջների փոփոխություններին՝ հնարավորություն ստանալով նոր բիզնես հնարավորություններ գրավել:

Հաճախ տրվող հարցեր

Ի՞նչ սպասարկման պահանջներ են սպասվում MS խողովակներ արտադրող մեքենայի համար:

Սովորաբար պարբեշխանային սպասարկումը ներառում է գլանների ստուգում և հարթեցում, լցակավորման համակարգի կարգավորում և շարժվող մասերի յուղում: Շատ արտադրողներ խորհուրդ են տալիս օրական տեսողական ստուգումներ, շաբաթական մեխանիկական ստուգումներ և եռամսյակային լրիվ սպասարկում՝ ապահովելու համար օպտիմալ աշխատանք և երկար ծառայության ժամկետ:

Որքա՞ն ժամանակ է պահանջվում MS խողովակներ արտադրող մեքենայի օպերատորներին վերապատրաստելու համար:

Հիմնական օպերատորի վերապատրաստումը սովորաբար տևում է 1-2 շաբաթ, ներառյալ սարքավորումների շահագործում, անվտանգության կանոններ և հիմնական խափանումների վերացում: Կարգավորման և սպասարկման անձնակազմի համար բարդացված վերապատրաստումը կարող է պահանջել լրացուցիչ 2-3 շաբաթ: Շատ արտադրողներ ձեռք բերման փաթեթի մասն են կազմում համապարփակ վերապատրաստման ծրագրեր:

Որքա՞ն տեղ է անհրաժեշտ MS խողովակի արտադրման սարքավորման տեղադրման համար:

Սովորաբար MS խողովակի արտադրման սարքավորումը պահանջում է նվազագույնը 15-20 մետր երկարությամբ և 3-4 մետր լայնությամբ հատակային տարածք՝ ներառյալ նյութերի տեղափոխման և արտադրանքի պահեստավորման համար: Լրացուցիչ տարածք պետք է նախատեսվի սպասարկման հասանելիության և օժանդակ սարքավորումների համար, ինչպիսիք են մանրացուցիչները և երկարությամբ կտրման համակարգերը: