Բարձր հաճախականությամբ էլեկտրական սեղմման հեղափոխական ազդեցությունը ժամանակակից խողովակների արտադրության մեջ

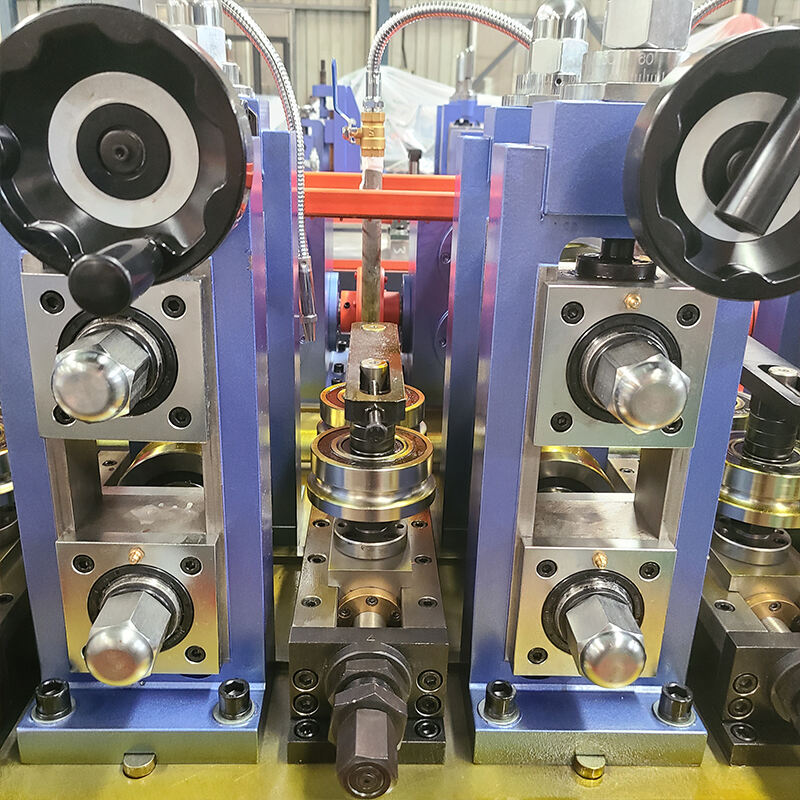

Արդյունաբերական արտադրության զարգացող համատեքստում բարձր հաճախականությամբ էլեկտրական սեղմմամբ խողովակների արտադրման սարքավորումներ դարձել են հիմնաքար տեխնոլոգիա, որը փոխակերպում է խողովակների արտադրության եղանակները տարբեր կիրառությունների համար: Այս բարդ համակարգերը միավորում են ճշգրիտ ինժեներական լուծումներ և առաջադեմ լցակայքային տեխնիկաներ՝ ստեղծելով անընդմեջ, հաստատուն խողովակներ, որոնք համապատասխանում են ամենախիստ արդյունաբերական ստանդարտներին: Բարձր հաճախականությամբ լցակայքավորված խողովակակազմ գործարանների տեխնոլոգիան ներկայացնում է զգալի առաջընթաց ավանդական խողովակների արտադրության մեթոդներից, ապահովելով աննախադեպ արդյունավետություն, հաստատականություն և որակի վերահսկողություն:

Արտադրական ոլորտում տեղի է ունեցել դեպի ավտոմատացված և ավելի ճշգրիտ արտադրական մեթոդների շատ մեծ տեղաշարժ, որտեղ առաջատար դեր են խաղում բարձր հաճախականությամբ սեղմված խողովակային գործարանները խողովակային արտադրանքների արտադրության մեջ: Այս արդյունավետ համակարգերը օգտագործում են էլեկտրամագնիսական ինդուկցիա՝ ստեղծելով ամուր, վստահելի սեղմումներ այնպիսի արագություններով, ինչպիսին նախկինում անհնար էր պատկերացնել: Արդյունքում ստացվում է արտադրական գործընթաց, որը ոչ միայն համապատասխանում է արդի արդյունաբերական պահանջներին, այլև սահմանում է նոր չափանիշներ որակի և արդյունավետության համար:

Ընդարձակ տեխնոլոգիա և գործառնական սկզբունքներ

Էլեկտրամագնիսական ինդուկցիայի գործընթաց

Բարձր հաճախականությամբ էլեկտրական կապով խողովակների արտադրության գործարանները աշխատում են էլեկտրամագնիսական ինդուկցիայի սկզբունքով, երբ էլեկտրական հոսանքը կենտրոնանում է մետաղական շերտի եզրերին, որը ձևավորվում է խողովակի տեսքով: Այս էներգիայի կենտրոնացումը ստեղծում է ինտենսիվ տեղային տաքացում, որն ապահովում է ճշգրիտ և մաքուր կապ, առանց չափազանց տաքացնելու շրջակա մասերը: Այս գործընթացը հսկվում է բարդ հսկման համակարգերի միջոցով, որոնք արտադրության ընթացքում ապահովում են կապման օպտիմալ պարամետրերի պահպանում:

Բարձր հաճախականությամբ հոսանքը շարժվում է մետաղի մակերեսով՝ ստեղծելով այն, ինչ հայտնի է որպես «մաշկի էֆեկտ»: Այս երևույթն ունի հիմնարար նշանակություն կապման իդեալական ջերմաստիճանին հասնելու համար՝ արագ և արդյունավետ, ինչը արդյունքում տալիս է ուժեղ մետաղական կապ խողովակի կապի մասում: Տաքացման գործընթացի ճշգրիտ վերահսկումը օգնում է կանխել նյութի դեֆորմացիան և պահպանել հիմնական մետաղի մեխանիկական հատկությունները:

Ավտոմատացված կառավարման համակարգեր

Ժամանակակից բարձր հաճախականությամբ էլեկտրական սեղմակայված խողովակների գործարանները ներառում են առաջադեմ ավտոմատացման համակարգեր, որոնք իրական ժամանակում հսկում և կարգավորում են տարբեր պարամետրեր: Այդ համակարգերը վերահսկում են շերտի հարթակման և ձևավորման ճնշումից մինչև լցումային ջերմաստիճանն ու սառեցման արագությունը: Սենսորների և հակադարձ կապի մեխանիզմների ինտեգրումը ապահովում է արտադրության ընթացքում հաստատուն որակ՝ նվազագույնի հասցնելով տատանումները, որոնք կարող են ազդել վերջնական արտադրանքի վրա:

Ավտոմատացումը տարածվում է նաև որակի վերահսկման միջոցառումների վրա, ներառյալ արտադրության շղթայում անթերիությունները հայտնաբերելու և նշելու սարքավորումներ: Այս մակարդակի հսկողությունը օգնում է պահպանել բարձր արտադրական ստանդարտներ՝ նվազեցնելով թափոններն ու վերամշակման անհրաժեշտությունը:

Արտադրության արդյունավետություն և ելքի որակ

Արագության և արտադրողականության առավելություններ

Բարձր հաճախականությամբ էլեկտրական սեղմակայված խողովակների արտադրության գործարանները առավելագույնս արագ արտադրական արագությամբ են աշխատում, որոնք կարող են արտադրել խողովակներ զգալիորեն ավելի բարձր տեմպերով, քան հասարակ մեթոդները: Անընդհատ արտադրական գործընթացը՝ համակցված ճշգրիտ կառավարման համակարգերի հետ, թույլ է տալիս ապահովել բարձր արագությամբ աշխատանք՝ առանց որևէ կերպ վնասելու որակին: Այս ավելի բարձր արտադրողականությունը անմիջապես նշանակում է ավելի բարձր արտադրական արդյունավետություն և ավելի մատչելի արժեք արտադրողների համար:

Պահպանել հաստատուն որակ բարձր արտադրական արագությամբ հատկապես կարևոր է խոշորամասշտաբ նախագծերի պահանջները բավարարելու համար: Արտադրվում են այդ խողովակները շինարարության, ենթակառուցվածքների կամ արդյունաբերական կիրառությունների համար, բարձր հաճախականությամբ էլեկտրական սեղմակայված խողովակների արտադրության գործարանները կարող են ապահովել անհրաժեշտ ծավալները՝ պահպանելով խիստ որակի ստանդարտներ:

Պրոդուկտի որոշակիության և որոշակիության ապահովում

Բարձր հաճախականությամբ էլեկտրական սեղմակային խողովակների գործարաններում որակի վերահսկողությունը համապարփակ և անընդհատ է: Կապակցման գործընթացը հսկվում է մի շարք պարամետրերով, ներառյալ ջերմաստիճանը, ճնշումը և արագությունը, որպեսզի համոզվենք, որ յուրաքանչյուր խողովակը համապատասխանում է սահմանված պահանջներին: Արտադրական գծին ինտեգրված են առաջադեմ փորձարկման մեթոդներ, ինչպիսիք են փոխադարձ հոսանքների փորձարկումը և ուլտրաձայնային զննումը՝ համոզվելու համար կապակցման ամբողջականության և ընդհանուր խողովակի որակի մասին:

Այս որակի վերահսկողության միջոցներով հասնելով հաստատականության՝ արտադրվում են այնպիսի արտադրանքներ, որոնք համապատասխանում կամ գերազանցում են արդյունաբերական ստանդարտները: Այս հուսալիությունը կարևոր է այն դեպքերում, երբ խողովակի ձախողումը կարող է լուրջ հետևանքներ ունենալ, օրինակ՝ նավթի և գազի տեղափոխման կամ կառուցվածքային կիրառությունների դեպքում:

Տնտեսական օգուտներ և շուկայական առավելություններ

Ծախսերի արդյունավետությունը արտադրության մեջ

Բարձր հաճախականությամբ էլեկտրական սեղմմամբ խողովակների արտադրության տնտեսական առավելությունները զգալի են: Ավտոմատացված գործընթացը պահանջում է փոքր թվով օպերատորներ, միևնույն ժամանակ պահպանելով բարձր արտադրողականություն, ինչը հանգեցնում է արտադրված միավորի աշխատանքի ցածր ծախսերի: Ավելին, սեղմման գործընթացի ճշգրիտ վերահսկողությունը հանգեցնում է նյութի նվազագույն թափոնների և էներգիայի սպառման կրճատման՝ համեմատած ավանդական սեղմման մեթոդների հետ:

Արտադրության գործընթացի արդյունավետությունը նաև նշանակում է ավելի կարճ արտադրության ժամկետներ և ավելի ճկուն արտադրական ծրագրավորում, որը թույլ է տալիս արտադրողներին արագ արձագանքել շուկայի պահանջներին: Արտադրության ծրագրավորման այս ճկունությունը կարող է տալ զգալի մրցակցային առավելություն այսօրվա արագ ընթացող շուկայական միջավայրում:

Շուկայի մրցունակություն

Բարձր հաճախականությամբ էլեկտրական սեղմակայված խողովակների արտադրության գործարանների օգտագործումը թույլ է տալիս արտադրողներին առաջարկել մրցակցային գներ՝ պահպանելով շահույթի մարժանները, ինչը հնարավոր է արտադրության ցածր ծախսերի և բարձր արտադրողականության շնորհիվ: Մեծ որակի խողովակների անընդհատ արտադրությունը նաև հնարավորություն է բացում պրեմիում շուկաներում, որտեղ որակի նկատմամբ պահանջները շատ խիստ են:

Բարձր հաճախականությամբ էլեկտրական սեղմակայված խողովակների արտադրության գործարանների տարբերակների բազմազանությունը թույլ է տալիս արտադրողներին սպասարկել շատ շուկայական հատվածներ, սկսած շինարարությունից և գյուղատնտեսությունից մինչև հատուկ արդյունաբերական կիրառություններ: Արտադրանքի տարասեռությունը օգնում է ընկերություններին պահպանել ուժեղ դիրք շուկայում և հարմարվել փոխվող շուկայական պահանջներին:

娿vironmental և համարժեքության դիտարկումներ

Էներգետիկ արդյունավետություն

Բարձր հաճախականությամբ էլեկտրական սեղմակայված խողովակների արտադրության գործարանները խողովակների արտադրության ավելի էկոլոգիապես իմաստուն ընտրություն են ներկայացնում: Լավացման ընթացքում ջերմային էներգիայի ճշգրիտ կիրառումը համեմատաբար զգալիորեն կրճատում է էներգակորուստները համեմատած ավանդական լավացման մեթոդների հետ: Այս արդյունավետությունը ոչ միայն նվազեցնում է շահագործման ծախսերը, այլ նաև նպաստում է ածխածրի հետքի կրճատմանը:

Կառավարվող լցնելու գործընթացի բնույթը նաև նշանակում է փոքր ջերմության կորուստ և լավ էներգիայի օգտագործում, ինչը համապատասխանում է ժամանակակից կայունության նպատակներին: Շատ կայաններ այժմ օգտագործում են վերականգնվող էներգիայի աղբյուրներ այս գործարանները էներգամատակարարելու համար՝ ավելի շատ բարելավելով դրանց շրջակա միջավայրի վրա ազդեցությունը:

Նյութի պահպանում

Բարձր հաճախականությամբ եռակցված խողովակաշարերի ճշգրտությունը հանգեցնում է արտադրության ընթացքում նյութական կորուստների նվազագույնի: Եռակցման գործընթացի ճշգրիտ վերահսկողությունը նվազեցնում է եռակցումից հետո մեխանիկական մշակման կամ վերջնական մշակման անհրաժեշտությունը, խնայելով նյութերը և նվազեցնելով թափոնները: Բացի այդ, գործընթացի հետևողականությունը նշանակում է ավելի քիչ մերժված արտադրանք, ինչը նպաստում է ռեսուրսների ավելի լավ օգտագործմանը:

Տարբեր նյութեր արդյունավետ մշակելու կարողությունը նաև թույլ է տալիս օգտագործել վերամշակված մետաղներ համապատասխան կիրառություններում՝ աջակցելով արդյունաբերության մեջ շրջանային տնտեսության նախաձեռնություններին:

Հաճախ տրվող հարցեր

Որո՞նք են բարձր հաճախականությամբ լցված խողովակների գործարանների հիմնական առավելությունները ավանդական մեթոդների նկատմամբ:

Բարձր հաճախականությամբ էլեկտրական սեղմակային խողովակների գործարանները առաջարկում են գերազանց արտադրության արագություն, հաստատուն որակ և լավագույն էներգաօգտագործում: Դրանք ապահովում են սեղմման գործընթացի ճշգրիտ վերահսկողություն, ինչը հանգեցնում է ավելի ուժեղ սեղմումների և ավելի քիչ թերությունների: Այս գործարանների ավտոմատ բնույթը նաև նվազեցնում է աշխատանքային ծախսերը և բարելավում է արտադրության ընդհանուր արդյունավետությունը:

Ինչպե՞ս են բարձր հաճախականությամբ էլեկտրական սեղմակային խողովակների գործարանները ապահովում արտադրանքի որակը:

Այս գործարանները ներառում են որակի վերահսկման բազմաթիվ միջոցառումներ, ներառյալ սեղմման պարամետրերի իրական ժամանակում հսկում, տողային փորձարկման սարքավորումներ և ավտոմատացված զննման համակարգեր: Գործընթացը անընդհատ հսկվում է և կարգավորվում՝ պահպանելով օպտիմալ սեղմման պայմանները, որը ապահովում է հաստատուն արտադրանքի որակ արտադրության ընթացքում:

Ո՞ր տեսակի խողովակներ կարող են արտադրվել բարձր հաճախականությամբ էլեկտրական սեղմակային խողովակների գործարանների միջոցով:

Բարձր հաճախականությամբ էլեկտրական սեղմմամբ փողավոր գործարանները կարող են արտադրել խողովակների տարբեր չափեր և սպեցիֆիկացիաներ, որոնք հարմար են շինարարության, նավթի և գազի տեղափոխման, գյուղատնտեսական օգտագործման և արդյունաբերական գործընթացների համար: Նրանք կարող են աշխատել տարբեր նյութերի և պատերի հաստությունների հետ՝ ապահովելով տարբեր շուկայական պահանջներին համապատասխանելու ճկունություն:

Բովանդակության աղյուսակ

- Բարձր հաճախականությամբ էլեկտրական սեղմման հեղափոխական ազդեցությունը ժամանակակից խողովակների արտադրության մեջ

- Ընդարձակ տեխնոլոգիա և գործառնական սկզբունքներ

- Արտադրության արդյունավետություն և ելքի որակ

- Տնտեսական օգուտներ և շուկայական առավելություններ

- 娿vironmental և համարժեքության դիտարկումներ

-

Հաճախ տրվող հարցեր

- Որո՞նք են բարձր հաճախականությամբ լցված խողովակների գործարանների հիմնական առավելությունները ավանդական մեթոդների նկատմամբ:

- Ինչպե՞ս են բարձր հաճախականությամբ էլեկտրական սեղմակային խողովակների գործարանները ապահովում արտադրանքի որակը:

- Ո՞ր տեսակի խողովակներ կարող են արտադրվել բարձր հաճախականությամբ էլեկտրական սեղմակային խողովակների գործարանների միջոցով: