中国の自動車用パイプ製造機メーカー

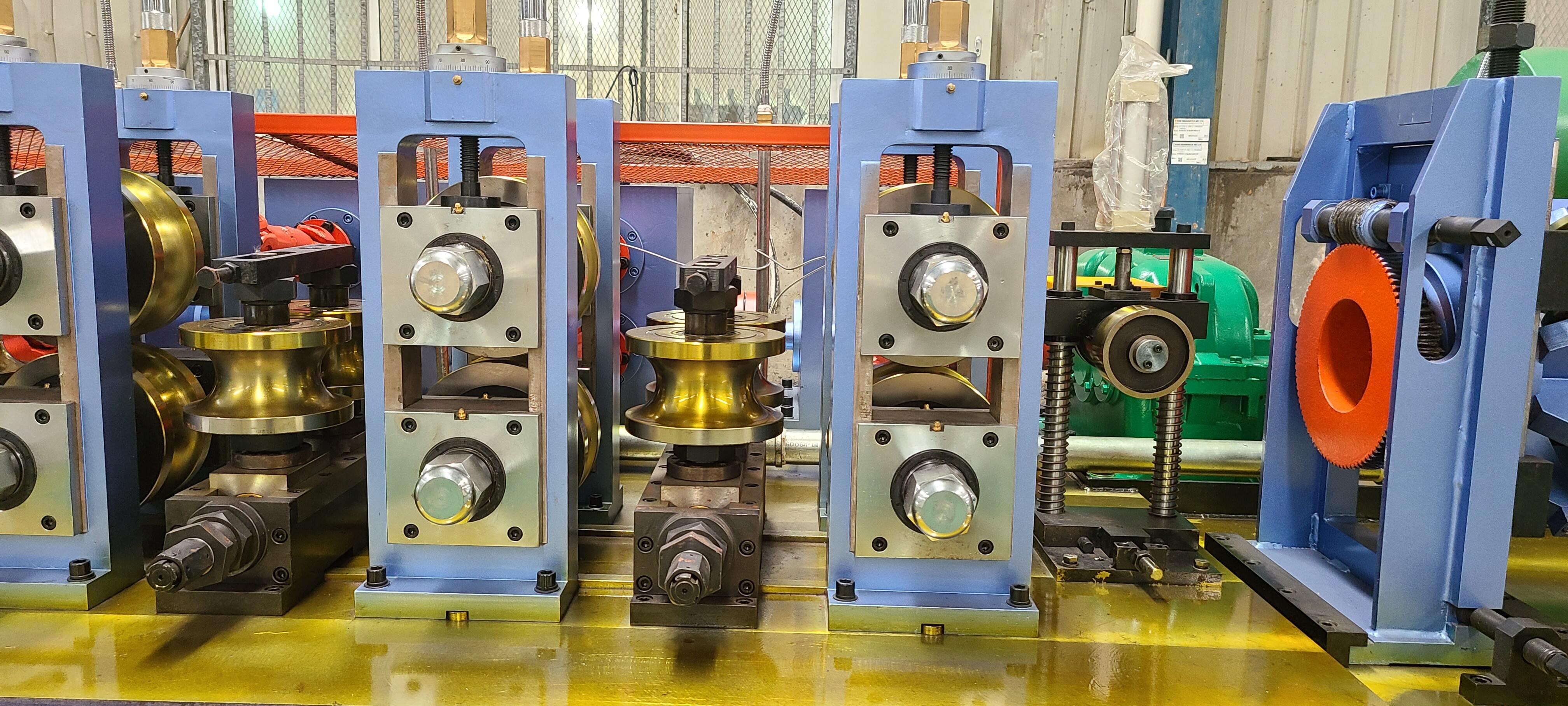

中国の自動車用パイプ製造機メーカーは、グローバルな自動車製造業において重要な基盤を形成しており、先進的な設備で車両部品を生産することに特化しています。これらのメーカーは最先端の技術を使用して、ブレーキライン、燃料ライン、油圧システムなど、さまざまな自動車用パイプを生産できる機械を作り出しています。これらの機械には精密なエンジニアリングが組み込まれており、自動カットシステム、高度な曲げ機構、一貫したパイプ生産を確保するための品質管理措置が特徴です。彼らの設備には通常、CNC制御された操作、多軸操作機能、各生産されたパイプの強度を確認する統合テストシステムが含まれています。これらのメーカーは、鋼、アルミニウム、銅などの複数の素材に対応可能な洗練された生産ラインを開発しており、異なる直径や壁厚のパイプを作成する能力を持っています。また、効率的な切り替えシステムが設計されており、異なるパイプ仕様間での迅速な調整が可能で、生産ダウンタイムを削減します。現代的な安全機能とエネルギー効率の高い運転が標準装備されており、国際的な製造基準や環境規制に適合しています。さらに、これらのメーカーは包括的なアフターサービスも提供しており、技術研修、メンテナンスサービス、部品供給が含まれます。