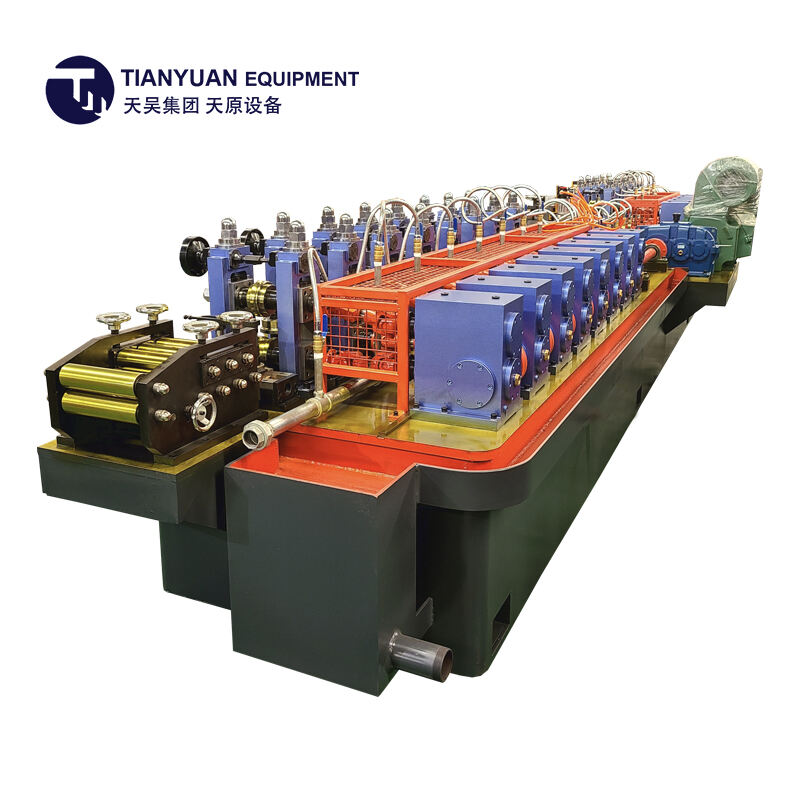

鋼管製造機

鋼管製造機は、自動化プロセスを通じて高品質の鋼管を生産するための洗練された製造ソリューションを表しています。この最先端の設備は、精密なエンジニアリングと最先端技術を組み合わせて、生の鋼材をさまざまな仕様の耐久性のある鋼管に変えることができます。この機械は、材料供給、成形、溶接、仕上げ工程などの複数の段階で動作します。コアテクノロジーは、一貫した鋼管寸法と優れた構造的強度を確保するための高度なロールフォーミング技術を利用しています。この機械の多機能性により、小口径の配管から大口径の工業用チューブまで、調整可能なパラメータで多様な製造要件に対応できる鋼管を生産することができます。インテリジェントな制御システムを備え、生産サイクル全体で正確な公差を維持し、材料の無駄を最小限に抑え、生産効率を最適化します。自動品質管理機構の統合により、各鋼管が厳しい業界標準を満たすことが確実です。用途は建設、石油・ガス輸送、工業用流体システム、構造支持フレームワークなど、複数の分野にわたります。モジュラー設計の機械は、メンテナンスやアップデートが簡単であり、堅牢な構造により過酷な工業環境での長期的な信頼性が確保されています。