ეფექტური hf სველი მწვანე მილი

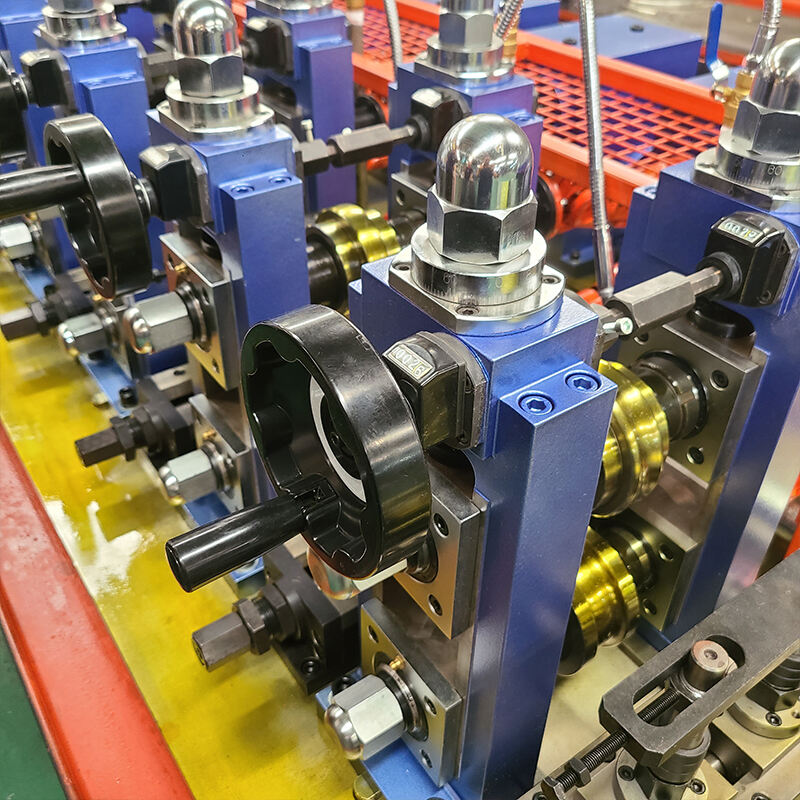

Ეფექტური HF საკრუმო მილი წარმოადგენს ინნოვაციურ შემსრულების ამოხსნას, რომელიც შე祺ავებულია ზუსტ ინჟინრингთან და მაღალი სიხშირის საკრუმო ტექნოლოგითან. ეს მოდერნული სისტემა ეფექტურად წარმოადგენს საკრუმო სპირალებს უწყვეტ პროცესში, რომელიც იწყება სპირალის ფორმის სპირალით და დამთავრდება მთავარი სპირალი. მილი შეიცავს მოდერნულ ფორმირების ტექნოლოგიას, რომელიც გამოიყენება მრავალფეროვან როლების სისტემებით, რომლებიც მაღალი სიხშირის საკრუმოს გამოყენების წინ ანათებს სპირალს ფორმირების პროცესში. პროცესი უზრუნველყოფს გამოსახულ საკრუმო ხარისხს ზუსტი ტემპერატურის კონტროლის და წნევის გამოყენებით. მილის ავტომაციური სისტემები შეიცავს ერთმანეთს მუშაობის სიჩქარეს და მართავს ხარისხის პარამეტრებს რეალურ დროში. ძირითადი ტექნოლოგიური მახასიათებელები შეიცავს ციფრულ კონტროლს ზუსტი განზომილების მიხედვით, ავტომაციურ მართვის სისტემებს ეფექტური მუშაობისთვის და სოფისტიკაციურ ხარისხის შემოწმების მოწყობილობებს. მილი შეიძლება წარმოადგენს სპირალებს 20 მმ-დან 165 მმ-მდე დიამეტრით და 1.5 მმ-დან 6 მმ-მდე სიღრმით, რაც განსაზღვრავს მის ვერსატილობას განსაკუთრებული გამოყენებისთვის. ეს სპირალები მასში გამოიყენება საშენო სფეროში, ინფრასტრუქტურის განვითარებაში, სითხის ტრანსპორტირებაში და სტრუქტურული გამოყენებებში. სისტემის მოდერნული კალიბრირების შესაძლებლობები უზრუნველყოფს გარბენებას და წრიულობას საერთაშორისო სტანდარტების მიხედვით, ხოლო ინტეგრირებული გამოსათხული სისტემა ოპტიმიზებს საკრუმო გამოსახულ მეტალურგიულ სტრუქტურას.