მს კვადრატული მაღალი გამოყენების მაशინა

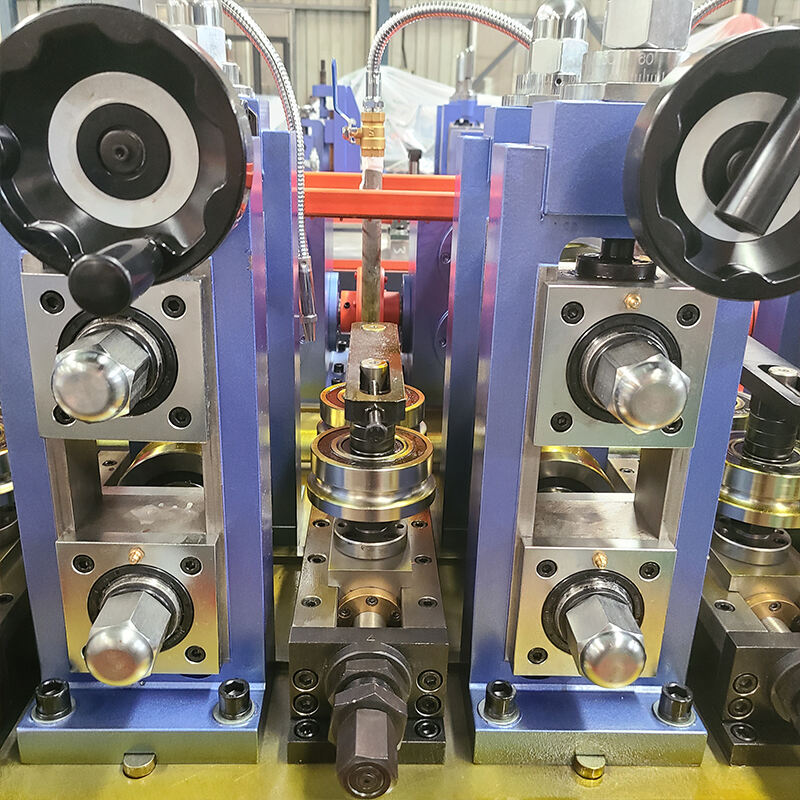

Მანქანა MS კვადრატული საბურთელო შექმნისთვის არის სახიფანგო წარმოების მანქანა, რომელიც შექმნილია სამრავლო და მართკუთხა მეტალურგიული საბურთელების წარმოებისთვის. ეს მოდერნული მანქანა იყენებს უახლოეს ტექნოლოგიას, რომლის მეშვეობითაც სიბრტყენი მეტალურგიული ფეროები გარდაქმნილია ზუსტად ფორმილებულ კვადრატულ ტუბებად სისტემურ როლ-ფორმირების პროცესით. მანქანაში არის რამდენიმე ფორმირების საკონტროლო საკუთარი საკონტროლო საკუთარი, რომლებიც პროგრესულად ფორმილებს მასალას, რათა დარწმუნდეს ერთსამანეთში ერთსამანეთში განზომილებების და უკეთესი სველის ხარისხის შესახებ. მისი ავტომატური კონტროლის სისტემა შეინარჩუნებს ზუსტ მუშაობის პარამეტრებს, მათ შორის სიჩქარის კონტროლს, სველის ტემპერატურას და ჭრილის სიგრძეს, რათა მიიღოს ერთსამანეთში პროდუქტის ხარისხი. მანქანა შეიცავს განსხვავებულ მასალის thicnesses და შეიძლება წარმოადგინოს საბურთელები 20x20mm-დან 100x100mm-მდე, რაც გამოიწვევს მის ვერსატილობას განსხვავებულ ინდუსტრიულ აპლიკაციებში. ინტეგრირებული მაღალი სიხშირის სველის სისტემა დარწმუნებულია ძლიერი და მოსავალი სველის კავშირებით, ხოლო შეინახული გამყრივების სისტემა არ დააკარგავს მასალას მუშაობის დროს. განვითარებული საბეზრების მახასიათებლები, მათ შორის განახლების მექანიზმები და დაცული გარდები, დარწმუნებულია მუშაობის უსაფრთხოება პროდუქტიულობის გარეშე. მანქანის მძიმე კონსტრუქცია, რომელიც შეიცავს გამოჯიშულ მასალის როლებს და ზუსტად ინჟინირებულ კომპონენტებს, დარწმუნებულია გრძელვადი უნდასამართლო და მინიმალური მეცადების მოთხოვნები. ეს მანქანა არის ძვირი სამშენებლოში, მебლის წარმოებაში, ავტომობილურ ინდუსტრიაში და სტრუქტურულ აპლიკაციებში, სადაც საჭიროა ზუსტი კვადრატული ტუბები.