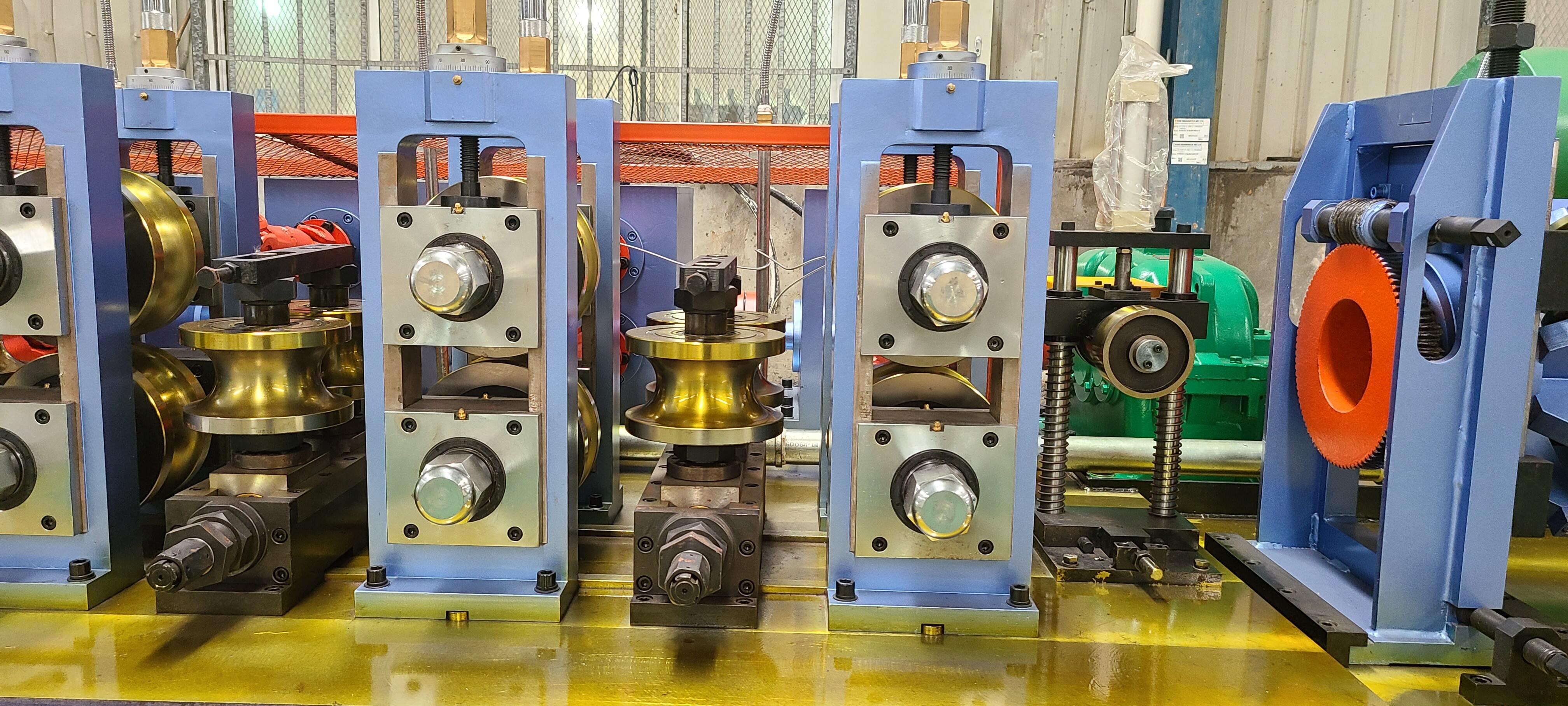

күчөлүк ауто жолу кылуучу машина

Күчтүү автомобилдик жылдыз төөлөгү чыгаруу машинасы автомобильдик көрмөнүнө каражаттык чечимдүү жаңычоо болуп саналат, ырыссыз анкара жана эмне-бир ар бирине каршы колдонулган автомобильдик жылдыздарды чыгаруу үчүн ырыстап жасалган. Бул мудрик машина күчтүү автоматика технологиясы мен механик инженердиниң күчтүү байланышынан фойдаланып, стандарттастык жылдыздарды тандоо үчүн туташтуу чыgarуу болобот. Машинада иштетиш параметрлерин реальдук убакытта көздөө жана чейинде тууратуу системада бар, чыгаруу сапасынын оптималдуу болушуна сай. Улундай үйгүлөрү: диаметрдеги даярдым, жыйындашуу жумуштары жана автоматтык узундугу бөлүшү бар, ал эч нерсе толерансдарды туташтуруу үчүн. Машиналык күчтүүлүгү ошондой эле күчтүү көздөө конструированиесинde бар, күчтүү темир компоненттери мен износкара жөнөндө материалдардан турат, бул эле унун кеңештүү операциялык жылдарын кеңейтүүгө көмөк кылат. Ошондой эле, ул сталь, алюминий жана көмүрдүк алынчылыктардын көпчүлүк материалдарын иштеп чыgaryп, бул эле түрлү автомобильдик жылдыздарга арналган. Системанын инновациялык дизайны автоматтык жылдыз mechanismsи, жыйындашуу технологиясы жана сапкы чектеу үчүн мудрик чекитиш үчүн мүмкүнчilik берет, эң аз оператордук катарда эле жылдыз чыгаруу үчүн. Бул машина чыгаруу убакытын азыртат жана сапкастан башка сапкастан чейинде тууратуу стандарттарды туташтуруу үчүн, автомобильдик көрмөнүнүн чыгаруу объекттеринde көпчүлүк катарда эле көп мөмкүнчilik берет.