төмөнкү баа hf көчүрүлгөн түбә жылытуу майлыгы

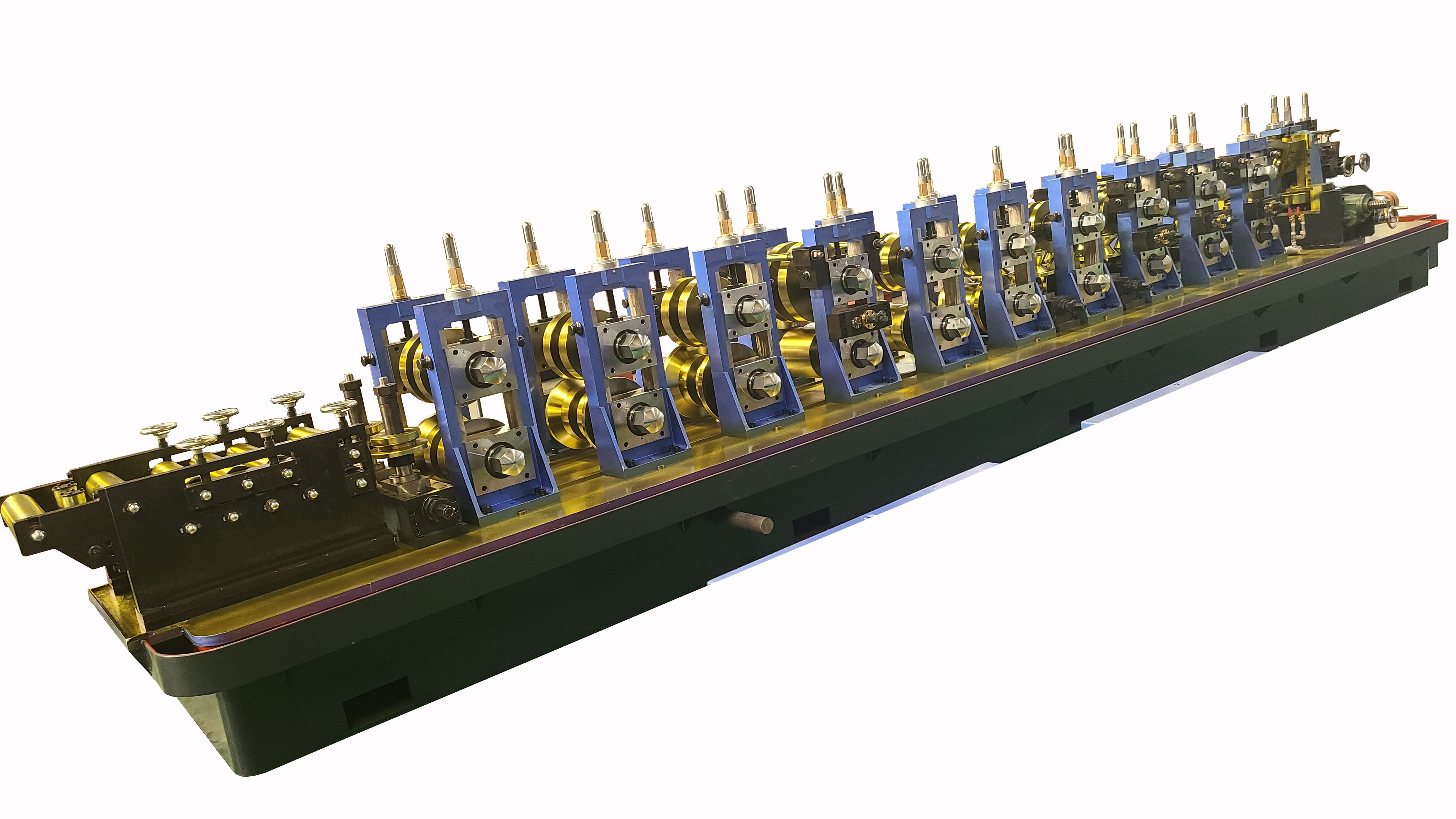

Ар кыймырлы HF жылдыз болуу майлысы маңызды жылдыздарды өндүрүү үчүн жакшылык тууралуу чечимдүү тизме. Бул ээлиндик өндүрүү системасы зоруктуу инженердик билим менен азырча өндүрүү мүмкүnlүктөрүн бириктирүүгө жол берет, буларда өзгөчө жылдыздардын стандарттары бар көп санда эле индустриялар үчүн уюшулат. Майлык ар кыймырлы HF жылдыз болуу технологиясын коркунуч салгандыгын жана структуралык толукчулукту таандайды. Өндүрүү линиясынын ичинде коилди башкаруу жабдыклары, жолдоо системалары, формалоо станциялары, жылдыз болуу блоктары, размерланыш секциялары жана кесүү механизмдеринен турат. Сапарга жеткен жылдыздардын диаметри 20мм-ден 165мм-ге чейин, жана жакындыгы 1.2мм-ден 6мм-ге чейин түзөт. Тизме автоматтык башкаруу жана мониторинг системаларында эч кандай процестерде анык абдандалуу жана жылдыз болуу сапарын таандайды. Модульдуу дизайны окуй төмөнүнүн өзгөртүүсүн жогорку кылууга жана өндүрүү процессине араласу аралыгын минималдуу кылат, жумуштуу эффективдикти жогорку кылат. Майлыктын ар кыймырлы баасы бизнеслерге жылдыздарды өндүрүү мүмкүnlүктөрүн куруу жана кеңейтуү үчүн жакшы варианту болуп саналат, сапарга жеткен стандарттарды жогорку кылууга каршы чыгарбас.