ຊື້ເຄື່ອງຊ້າຍ gi pipe

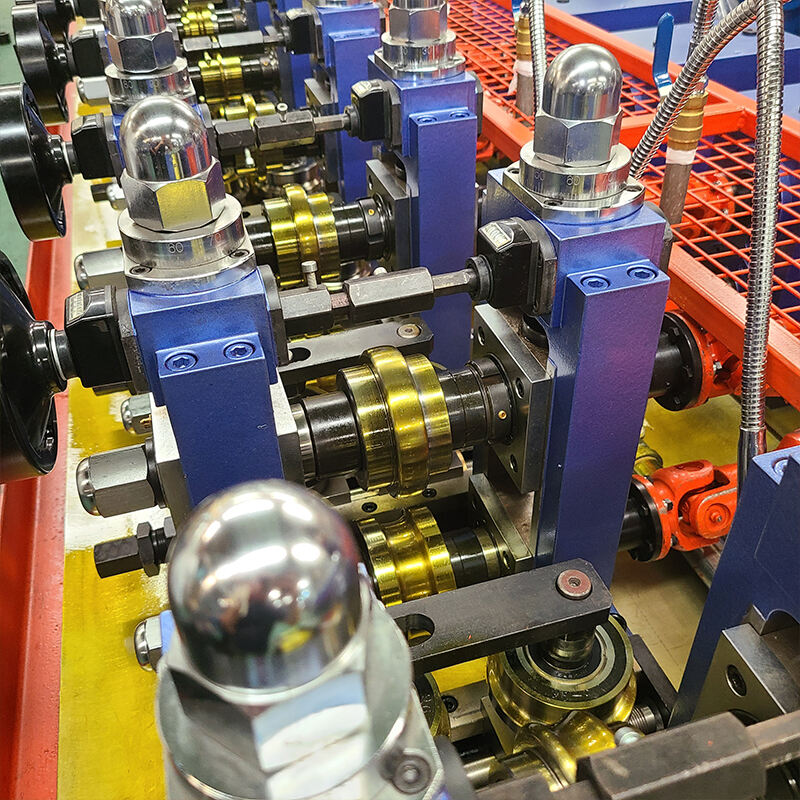

ເຄື່ອງປະຕີ້ມ້ານ GI ເປັນສິ່ງທີ່ແຫລ້ງການຜະລິດທີ່ຊຸດຍ້ອນໄປສຳລັບການຜະລິດທໍ່ເຫຼືອງເຊື້ອເຫຼັງທີ່ມີຄູນພຽງແລະຄຸນສະເພາະ. ການໃຊ້ເຄື່ອງຈັກທີ່ມີເทັກໂນໂລຊີ້ສູງສຸດນີ້ແມ່ນເພື່ອປ່ຽນແປງເຫຼືອງເຊື້ອເລີມຕົ້ນເປັນທໍ່ທີ່ຖືກຮູບແບບແລະແຫຼວຢ່າງແປກັນ. ເຄື່ອງມີລິນສຳລັບການຜະລິດທີ່ສຳເລັດທັງການເປັນ, ອັນ, ສີ, ຄັດ, ແລະ ການເຫຼືອງເຊື້ອ. ລະບົບຄວບຄຸມອັດຕະໂມາຕິກແມ່ນເພື່ອສົ່ງຜົນຄວາມຖືກຕ້ອງຂອງຂະໜາດແລະຄຸນສະເພາະຂອງການແຫຼວ. ມັນສາມາດຜະລິດທໍ່ທີ່ມີຄວາມແຫຼວ 15mm ຫາ 165mm ແລະສາມາດຮັບກັບຄວາມໜັງຂອງແຜ່ນຕາມຄຳສັ່ງຂອງລູກຄ້າ. ລະບົບຄວບຄຸມຄຸນສະເພາະທີ່ເຊື່ອມໂຍມີການຕິດຕາມທຸກຂັ້ນຂອງການຜະລິດ, ຕັ້ງແຕ່ການສົ່ງເຫຼືອງເຊື້ອເຖິງການກວດສອບທໍ່ສຸດທ້າຍ, ເພື່ອສົ່ງຜົນຄວາມສົງຄົມກັບສານຕະລານສາກົນ. ສາງກໍ່ທີ່ແຂງແໜ້ງແລະເທັກໂນໂລຊີ້ການແຫຼວທີ່ສູງສຸດແມ່ນສົ່ງຜົນຄວາມແຂງແລະຄຸນສະເພາະຂອງການແຫຼວ. ນຳໝູ່ 40 ແມັດເປັນປະມານ ທີ່ສົ່ງຜົນຄວາມສຳເລັດຂອງການຜະລິດ. ແລະລະບົບຄວບຄຸມຄວາມປອດໄພແລະສະເພາະສໍ້ສຳລັບຜູ້ໃຊ້, ເພື່ອສົ່ງຜົນຄວາມສະຫຼຸບສະຫຼຸງ.