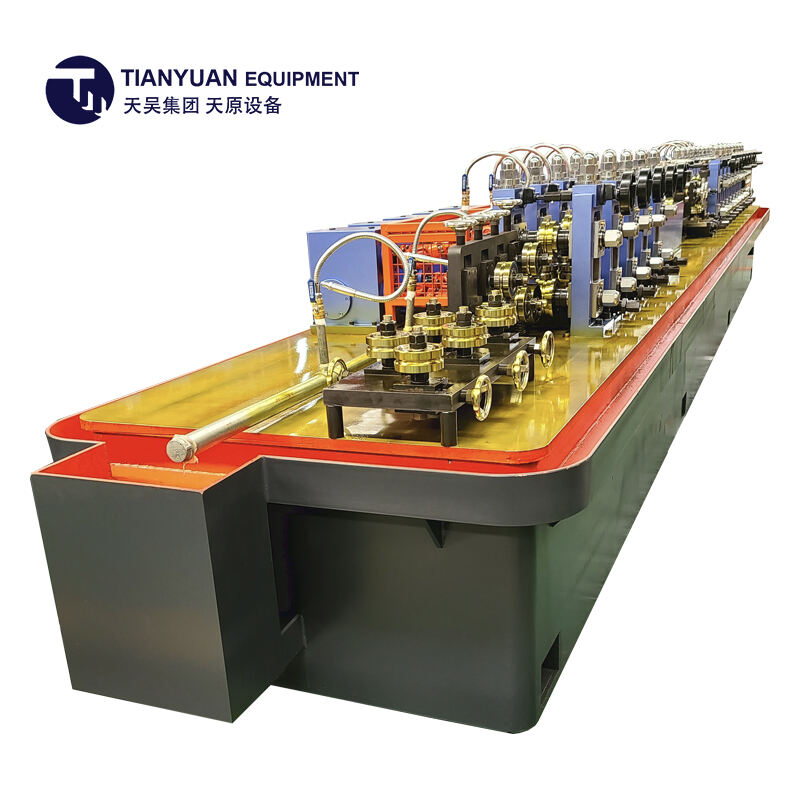

ເຄື່ອງຂັດແຫນວທີ່ສະແດງຜົນໄດ້ງ່າຍແລະປິ້ນໄດ້

ເຄື່ອງຂັດແຍງທີ່ຮັກສາໄດ້ງ່າຍແມ່ນການພັດທະນາທີ່ສຳຄັນໃນເทັກນົອລົジーການຊົ່ຽງປີບອິນເດຸສຕຣີ. ເຄື່ອງນີ້ທີ່ມີຄວາມປະສົມພັນສູງສາມາດປ່ຽນເປັນເຜິ່ນເຫຼົ້າເປັນປີບທີ່ມີຮູບແບບແນວໜ້າຈາກການລົງແລະການແຫຼວໂດຍສະເພາະ. ເຄື່ອງມີຮູບແບບການສ້າງທີ່ໜ້າຄວາມແຂງແຂ້ແລະມີການປະສົມປະສານຂອງຄວາມສົງສັນດິຈິຕໍ ເພື່ອການປະຕິບັດງານທີ່ໜ້າຄວາມຖືກຕ້ອງແລະຄຸນພາບການອອກມາທີ່ໜ້າຄວາມສະຫຼຸບສະຫຼັງ. ຂອງມັນມີການອອກແບບເພື່ອສະຫຼຸບສະຫຼັງການຮັກສາ, ກັບສ່ວນປະກອບທີ່ສາມາດຖືກເອົາອອກແລະສີ້ງໄດ້ງ່າຍ. ເຄື່ອງມີສະຖານຂັດແຍງຫຼາຍສະຖານທີ່ຄືນຄົນເຜິ່ນເຫຼົ້າເປັນປີບທີ່ມີຮູບແບບທີ່ຕ້ອງການ, ກັບລະບົບແຫຼວທີ່ປະສົມປະສານເພື່ອການແຫຼວສັນ. ອີງຕົວເທັກນົອລົງທີ່ສຳຄັນເປັນ: ຮອນຂັດແຍງທີ່ສາມາດແປງໄດ້, ລະບົບສົ່ງເສັ້ນທີ່ອຟເຕີມອຟໂຕ, ແລະລະບົບລົງທີ່ສຳຄັນເພື່ອການຢືນຢັນຄວາມຖືກຕ້ອງຂອງມື້. ເຄື່ອງສາມາດຜົນລົງປີບໃນຫຼາຍຄວາມແຫຼວແລະຄວາມໜັງ, ສາມາດເປັນໄປໄດ້ໃນຫຼາຍອິນເດຸສຕຣີ, ກັບການສ້າງສາ, ການພັດທະນາສານຕິ, ແລະການຊົ່ຽງ. ການສຳພາດທີ່ໃຊ້ງ່າຍຂອງມັນສາມາດໃຫ້ຜູ້ປະຕິບັດສະແດງຄວາມແຕ່ງແປງແລະລົງສະເພາະການຜົນລົງໃນເວລາຈິງ. ການປ່ອງກັນຄວາມປອດໄພ, ປະເທດການຢືນຢັນ, ແລະການປ່ອງກັນຄວາມປອດໄພ, ໄດ້ສັງຄັນການປະຕິບັດທີ່ໜ້າຄວາມປອດໄພ, ເນື່ອງຈາກການປົກຄອງຄວາມສຳເລັດ.