म्स ट्यूब मेकिंग मशीनचा किमत

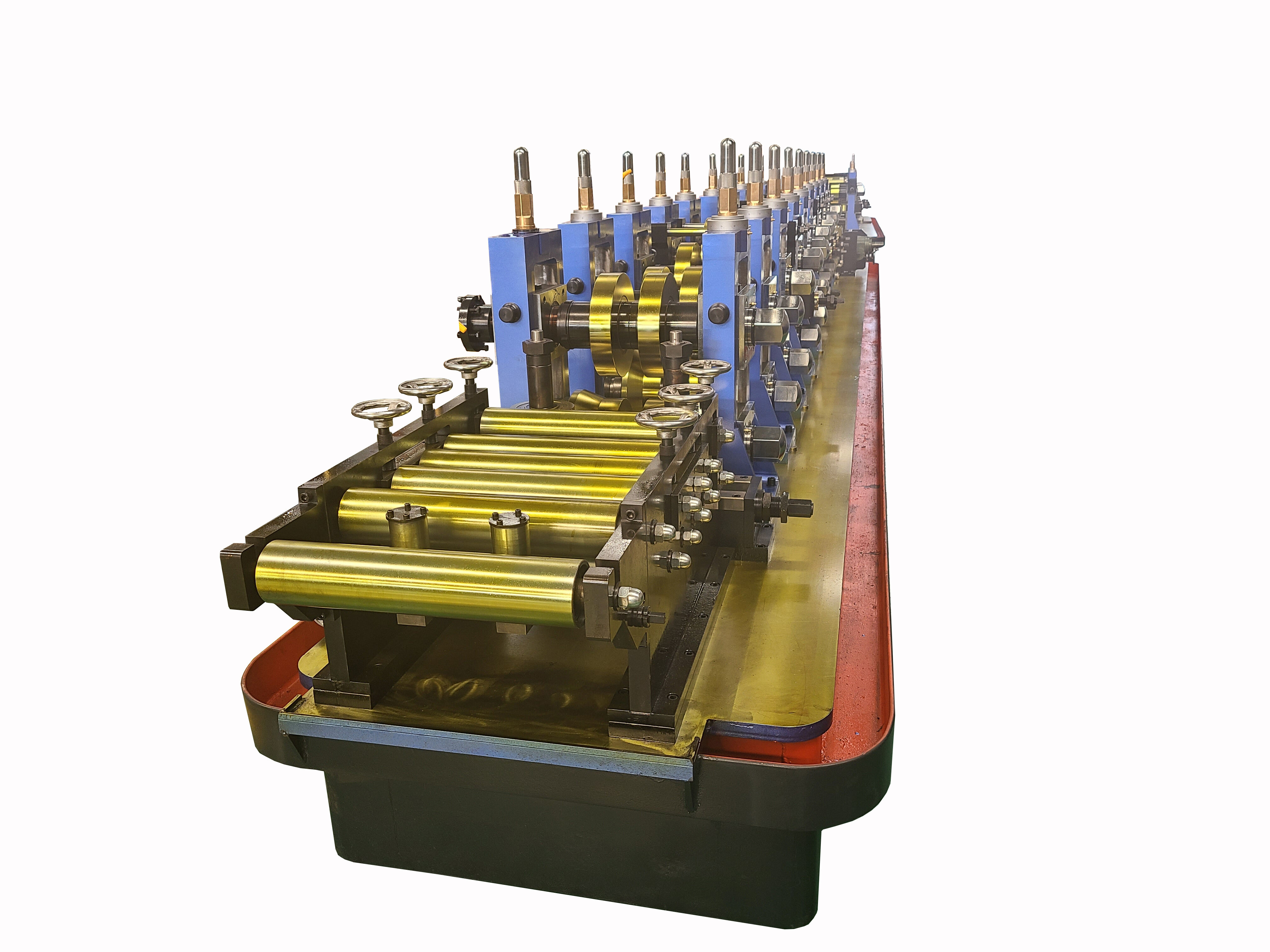

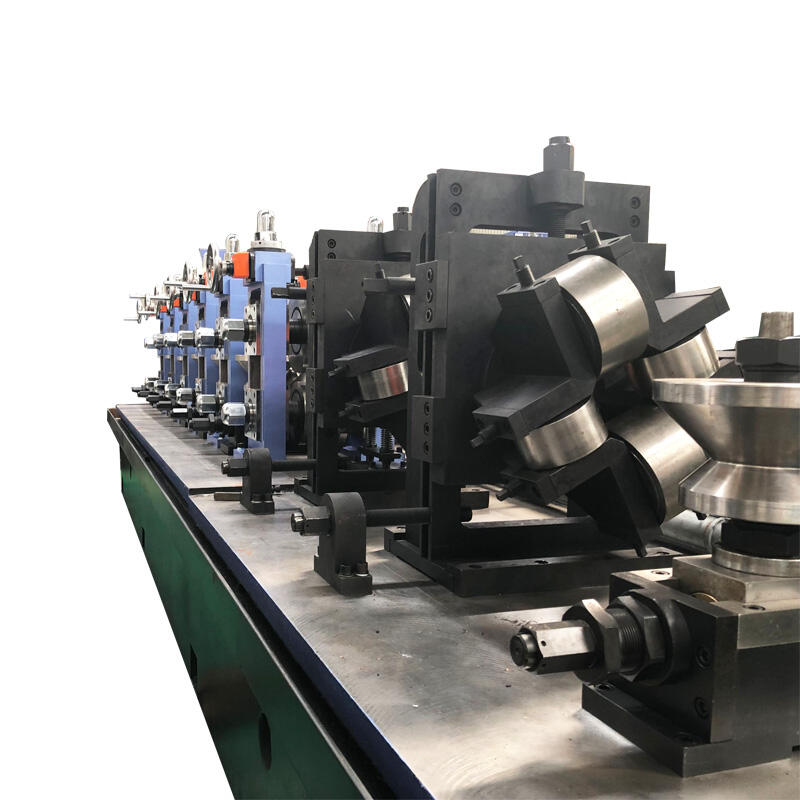

एमएस ट्यूब मेकिंग मशीनचा किमत वापरणवळी सेक्टरमध्ये महत्त्वपूर्ण निवड पर्याय म्हणून बघला जातो, उच्च गुणवत्तेच्या माल्ड स्टील ट्यूब्स तयार करण्यासाठी संपूर्ण समाधान प्रदान करतो. हे अग्रगामी उपकरण प्रत्यक्ष इंजिनिअरिंग आणि लागत-कुशल संचालनांचा संमिश्रण करते, ज्याची किमत क्षमता आणि विनियोजनामुळे $50,000 ते $200,000 पर्यंत असू शकते. या मशीनमध्ये लगातार ट्यूब तयार करण्यासाठी आधुनिक तंत्रज्ञान समाविष्ट आहे, ज्यामध्ये स्वचालित वेल्डिंग सिस्टम, प्रत्यक्ष फॉर्मिंग रोलर्स आणि उन्नत संचालन मेकेनिझम्स यांचा समावेश आहे. या मशीने 0.5mm ते 3mm या विस्तारातील स्टील स्ट्रिप्स प्रसेस करू शकतात आणि 15mm ते 100mm या व्यासातील ट्यूब्स तयार करू शकतात. या उपकरणात अनिवार्य घटकांमध्ये डिकोइलिंग युनिट, स्ट्रिप गाईडिंग सिस्टम, फॉर्मिंग स्टेशन, उच्च फ्रिक्वेंसीचे वेल्डिंग युनिट आणि काटून देण्यासाठी मेकेनिझम्स यांचा समावेश आहे. आधुनिक एमएस ट्यूब मेकिंग मशीन उपयोगकर्त्यांसाठी मित्रतापूर्ण इंटरफेस दिल्या गेल्या आहे, ज्यामुळे संचालकांना वेगवेगळ्या उत्पादन विनियोजनांसाठी पैरामीटर्स आसानपणे बदलू शकतात. या उपकरणाची बहुमुखीता वापरकर्त्यांना निर्माण, फर्निचर निर्माण, ऑटोमोबाइल घटक आणि कृषी सामग्री यासारख्या विविध उपयोगांसाठी ट्यूब्स तयार करण्यास सहायता करते. 20-80 मीटर प्रति मिनिट या उत्पादन वेगांमध्ये या मशीनांना नियमित गुणवत्ता मानकांचा पालन करत अच्छी आउटपुट क्षमता प्रदान करण्यात आलेली आहे.