Modern industrial manufacturing demands efficient and reliable production solutions, particularly in the steel pipe industry where precision and speed are paramount. A high-frequency welded pipe mill represents a sophisticated technological advancement that has revolutionized how manufacturers produce steel pipes across various industries. This advanced equipment combines cutting-edge engineering with proven manufacturing principles to deliver consistent, high-quality pipe production that meets the most demanding industrial specifications. The integration of high-frequency welding technology has transformed traditional pipe manufacturing processes, enabling manufacturers to achieve superior production rates while maintaining exceptional quality standards that exceed industry expectations.

Advanced Technology Behind High-Frequency Welded Pipe Manufacturing

High-Frequency Welding Process Fundamentals

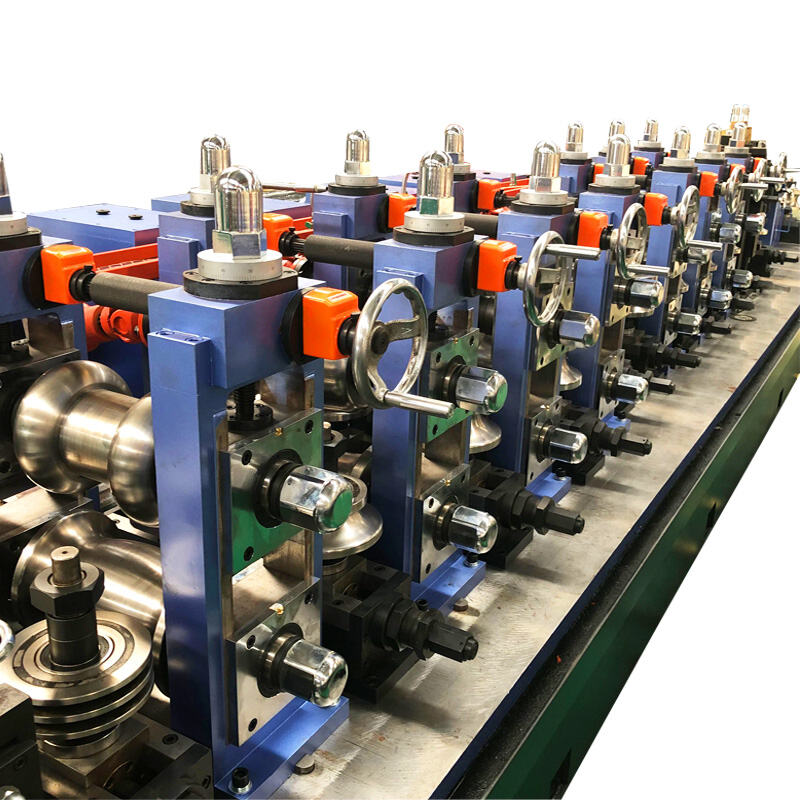

The high-frequency welding process utilized in a modern hf welded pipe mill operates on sophisticated electromagnetic principles that generate intense heat through resistance welding. This advanced technology creates a continuous weld seam by applying high-frequency electrical current to the steel strip edges as they are formed into pipe shape. The process generates temperatures exceeding 1000 degrees Celsius within milliseconds, ensuring complete fusion of the steel edges without compromising the material's structural integrity. This precise temperature control eliminates the need for additional welding materials, resulting in clean, strong weld seams that match the base material's properties.

The electromagnetic induction heating system in a hf welded pipe mill utilizes frequencies typically ranging from 200 to 450 kHz, depending on the pipe diameter and wall thickness requirements. This high-frequency energy penetrates only the surface layer of the steel, creating localized heating that minimizes thermal distortion throughout the pipe body. The rapid heating and cooling cycle preserves the steel's grain structure, maintaining excellent mechanical properties while achieving superior weld quality that exceeds traditional welding methods in both strength and consistency.

Precision Control Systems and Automation

Contemporary hf welded pipe mill systems incorporate sophisticated computerized control systems that monitor and adjust every aspect of the production process in real-time. These advanced control systems utilize multiple sensors and feedback loops to maintain precise welding parameters, including power output, welding speed, and pressure application throughout the entire production cycle. The integration of programmable logic controllers ensures consistent quality across different pipe specifications while enabling rapid changeovers between various pipe sizes and wall thicknesses without compromising production efficiency.

The automation capabilities of modern hf welded pipe mill equipment extend beyond basic parameter control to include predictive maintenance systems and quality assurance monitoring. Advanced diagnostic systems continuously analyze welding performance, detecting potential issues before they impact product quality or production efficiency. This proactive approach to equipment management significantly reduces downtime while ensuring consistent output quality that meets or exceeds industry standards for steel pipe manufacturing applications.

Production Efficiency and Economic Advantages

High-Speed Manufacturing Capabilities

A state-of-the-art hf welded pipe mill achieves remarkable production speeds that far exceed traditional pipe manufacturing methods, with modern systems capable of producing pipes at rates exceeding 200 meters per minute depending on pipe specifications. This exceptional speed advantage stems from the continuous nature of the high-frequency welding process, which eliminates the start-stop cycles associated with conventional welding methods. The seamless integration of forming and welding operations enables manufacturers to achieve consistent production flow while maintaining precise dimensional control across the entire pipe length.

The rapid production capabilities of a hf welded pipe mill translate directly into significant economic advantages for manufacturers operating in competitive markets. Higher throughput rates enable manufacturers to fulfill large orders more quickly while reducing per-unit production costs through improved equipment utilization. This efficiency advantage becomes particularly valuable when producing standard pipe sizes for construction, automotive, and infrastructure applications where volume requirements are substantial and delivery schedules are critical to project success.

Cost-Effective Manufacturing Operations

Operating a hf welded pipe mill offers substantial cost advantages compared to alternative pipe manufacturing methods, primarily through reduced material waste and energy consumption. The precise forming and welding process minimizes scrap generation while the high-frequency welding technique requires significantly less energy than traditional arc welding methods. Additionally, the elimination of consumable welding materials such as electrodes and flux compounds further reduces operational costs while simplifying inventory management and production planning.

The economic benefits of hf welded pipe mill operations extend to reduced labor requirements and simplified quality control procedures. Automated production processes require fewer skilled operators while built-in quality monitoring systems reduce the need for extensive post-production inspection procedures. These operational efficiencies enable manufacturers to allocate resources more effectively while maintaining consistent product quality that meets demanding customer specifications across various industrial applications.

Quality Control and Product Specifications

Superior Weld Quality and Consistency

The hf welded pipe mill produces weld seams with exceptional consistency and strength characteristics that often exceed the mechanical properties of the base material itself. The high-frequency welding process creates a narrow heat-affected zone that preserves the steel's original microstructure while achieving complete fusion along the weld line. This precise control over the welding process results in uniform weld penetration and consistent mechanical properties throughout the pipe length, ensuring reliable performance in demanding applications.

Quality assurance systems integrated into modern hf welded pipe mill equipment continuously monitor weld parameters and pipe dimensions throughout the production process. Advanced ultrasonic testing systems can detect minute imperfections in real-time, enabling immediate process adjustments to maintain optimal quality standards. This comprehensive quality control approach ensures that every pipe meets specified dimensional tolerances and mechanical property requirements before leaving the production line.

Dimensional Accuracy and Surface Finish

A precision hf welded pipe mill achieves exceptional dimensional accuracy across all pipe specifications, with modern systems capable of maintaining tolerances within ±0.1mm for outside diameter and wall thickness measurements. This precision stems from the controlled forming process that gradually shapes the steel strip into pipe form while maintaining consistent material flow and pressure distribution. The result is pipes with uniform wall thickness and precise outside diameter that meet the most demanding application requirements without requiring additional machining operations.

The surface finish quality achieved by a hf welded pipe mill surpasses traditional manufacturing methods, producing smooth, consistent surfaces that require minimal post-processing for most applications. The continuous forming process eliminates surface irregularities while the high-frequency welding technique produces clean weld seams without spatter or excess material buildup. This superior surface quality reduces finishing costs while improving the pipes' performance in applications where surface smoothness affects fluid flow characteristics or aesthetic requirements.

Industrial Applications and Market Versatility

Construction and Infrastructure Applications

The construction industry relies heavily on pipes produced by hf welded pipe mill systems for structural applications, water distribution systems, and HVAC installations where consistent quality and reliable performance are essential. These applications demand pipes with precise dimensional accuracy and superior weld integrity to ensure long-term structural stability and system reliability. The ability to produce various pipe sizes and wall thicknesses enables contractors to source all required specifications from a single manufacturer, simplifying procurement processes and ensuring consistent quality across entire projects.

Infrastructure projects including bridges, tunnels, and transportation systems utilize pipes manufactured using hf welded pipe mill technology for their critical structural components and utility systems. The superior strength-to-weight ratio achieved through precision manufacturing enables engineers to design more efficient structures while maintaining safety margins required for public infrastructure applications. The consistent quality and dimensional accuracy of these pipes facilitate faster installation procedures while reducing the risk of field modifications or rework during construction phases.

Automotive and Manufacturing Industries

Automotive manufacturers depend on hf welded pipe mill products for exhaust systems, chassis components, and hydraulic applications where weight reduction and performance optimization are critical design considerations. The precise dimensional control and superior surface finish achieved through high-frequency welding enable automotive engineers to design more efficient systems while meeting stringent emission and safety requirements. The ability to produce pipes with varying wall thicknesses along their length provides additional design flexibility for complex automotive applications.

Manufacturing industries utilize pipes from hf welded pipe mill systems for pneumatic conveying, process piping, and structural applications where reliability and cost-effectiveness are primary concerns. The consistent quality and dimensional accuracy enable manufacturers to implement automated assembly processes while reducing quality control requirements and associated costs. The superior weld quality ensures reliable performance in demanding industrial environments where system failures can result in significant production losses and safety concerns.

Equipment Selection and Implementation Considerations

Capacity Planning and Production Requirements

Selecting the appropriate hf welded pipe mill configuration requires careful analysis of production requirements, including anticipated volume levels, pipe size ranges, and quality specifications. Manufacturers must consider both current market demands and future growth projections when determining optimal equipment capacity and configuration options. The flexibility to produce multiple pipe sizes and wall thicknesses within a single production run becomes increasingly important for manufacturers serving diverse market segments with varying specification requirements.

Production planning for hf welded pipe mill operations must account for material supply logistics, quality control procedures, and downstream processing requirements to optimize overall manufacturing efficiency. The high production rates achievable with modern equipment require corresponding capabilities in material handling, quality inspection, and finished product storage to prevent bottlenecks that could limit overall system productivity. Proper integration of all production elements ensures maximum return on equipment investment while maintaining consistent quality standards.

Technology Integration and Modernization

Modern hf welded pipe mill systems offer extensive connectivity and data integration capabilities that enable manufacturers to implement Industry 4.0 principles and smart manufacturing strategies. These advanced systems provide real-time production data, predictive maintenance alerts, and quality trend analysis that support continuous improvement initiatives and operational optimization efforts. The ability to integrate with existing enterprise resource planning systems streamlines production planning and inventory management while providing comprehensive visibility into manufacturing operations.

Upgrading existing manufacturing facilities to incorporate hf welded pipe mill technology requires careful consideration of infrastructure requirements, including electrical power capacity, cooling systems, and material handling equipment. The high-frequency power systems require stable electrical supply and proper grounding to ensure consistent welding performance, while the high production rates necessitate efficient material flow systems to maintain continuous operation. Proper planning and implementation ensure successful technology integration while minimizing disruption to existing operations.

FAQ

What are the main advantages of using a hf welded pipe mill compared to traditional pipe manufacturing methods

A hf welded pipe mill offers several significant advantages over traditional manufacturing methods, including dramatically higher production speeds, superior weld quality, and reduced operational costs. The high-frequency welding process produces stronger, more consistent weld seams while operating at speeds that can exceed 200 meters per minute. Additionally, the process eliminates the need for consumable welding materials and reduces energy consumption, resulting in lower per-unit production costs and improved environmental efficiency.

How does the quality of pipes produced by a hf welded pipe mill compare to seamless pipes

Pipes manufactured using a hf welded pipe mill achieve quality levels that are comparable to seamless pipes for most applications, with the added advantage of precise dimensional control and superior surface finish. The high-frequency welding process creates weld seams with mechanical properties that often match or exceed those of the base material, while the continuous forming process ensures consistent wall thickness and diameter throughout the pipe length. For many applications, hf welded pipes provide equivalent performance at significantly lower costs than seamless alternatives.

What maintenance requirements should be considered for hf welded pipe mill equipment

Maintenance requirements for a hf welded pipe mill include regular inspection and replacement of forming rolls, high-frequency welding components, and cutting systems to ensure consistent production quality. The high-frequency power systems require periodic calibration and component replacement according to manufacturer specifications, while the forming sections need regular lubrication and wear monitoring. Implementing predictive maintenance programs using built-in diagnostic systems can significantly reduce unplanned downtime while optimizing equipment performance and extending component life.

What factors determine the maximum pipe sizes and wall thicknesses achievable with a hf welded pipe mill

The maximum pipe sizes and wall thicknesses achievable with a hf welded pipe mill depend on the equipment's forming capacity, high-frequency power output, and mechanical design limitations. Typically, modern systems can produce pipes ranging from small diameter tubes up to 600mm or larger, with wall thicknesses from thin-wall applications to heavy-wall structural pipes. The specific capabilities vary by manufacturer and equipment configuration, with larger systems offering greater size flexibility but requiring higher capital investment and operating costs.

Table of Contents

- Advanced Technology Behind High-Frequency Welded Pipe Manufacturing

- Production Efficiency and Economic Advantages

- Quality Control and Product Specifications

- Industrial Applications and Market Versatility

- Equipment Selection and Implementation Considerations

-

FAQ

- What are the main advantages of using a hf welded pipe mill compared to traditional pipe manufacturing methods

- How does the quality of pipes produced by a hf welded pipe mill compare to seamless pipes

- What maintenance requirements should be considered for hf welded pipe mill equipment

- What factors determine the maximum pipe sizes and wall thicknesses achievable with a hf welded pipe mill