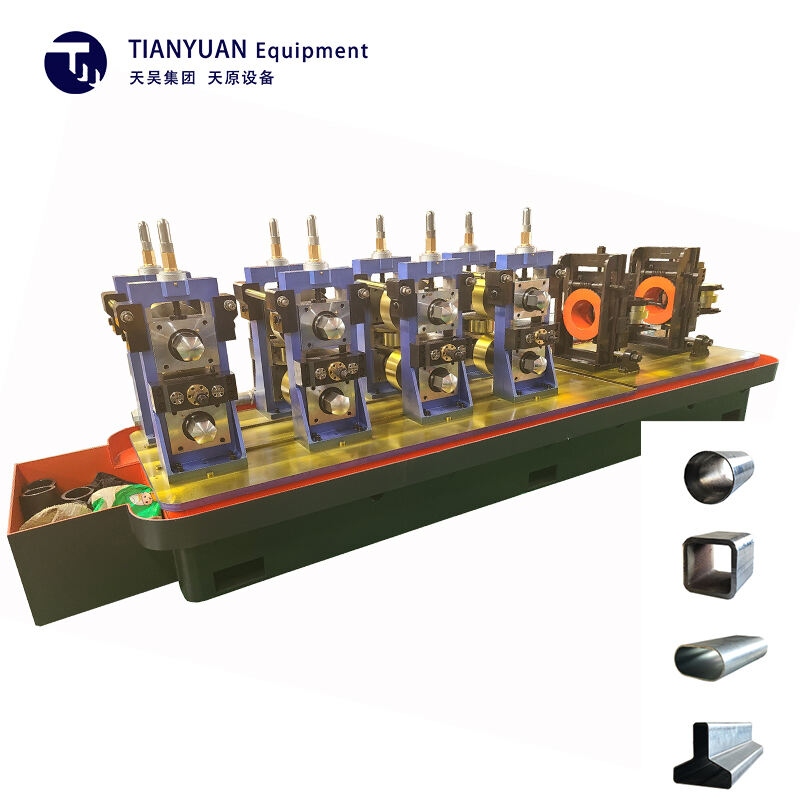

maszyna do formowania rur stalowych

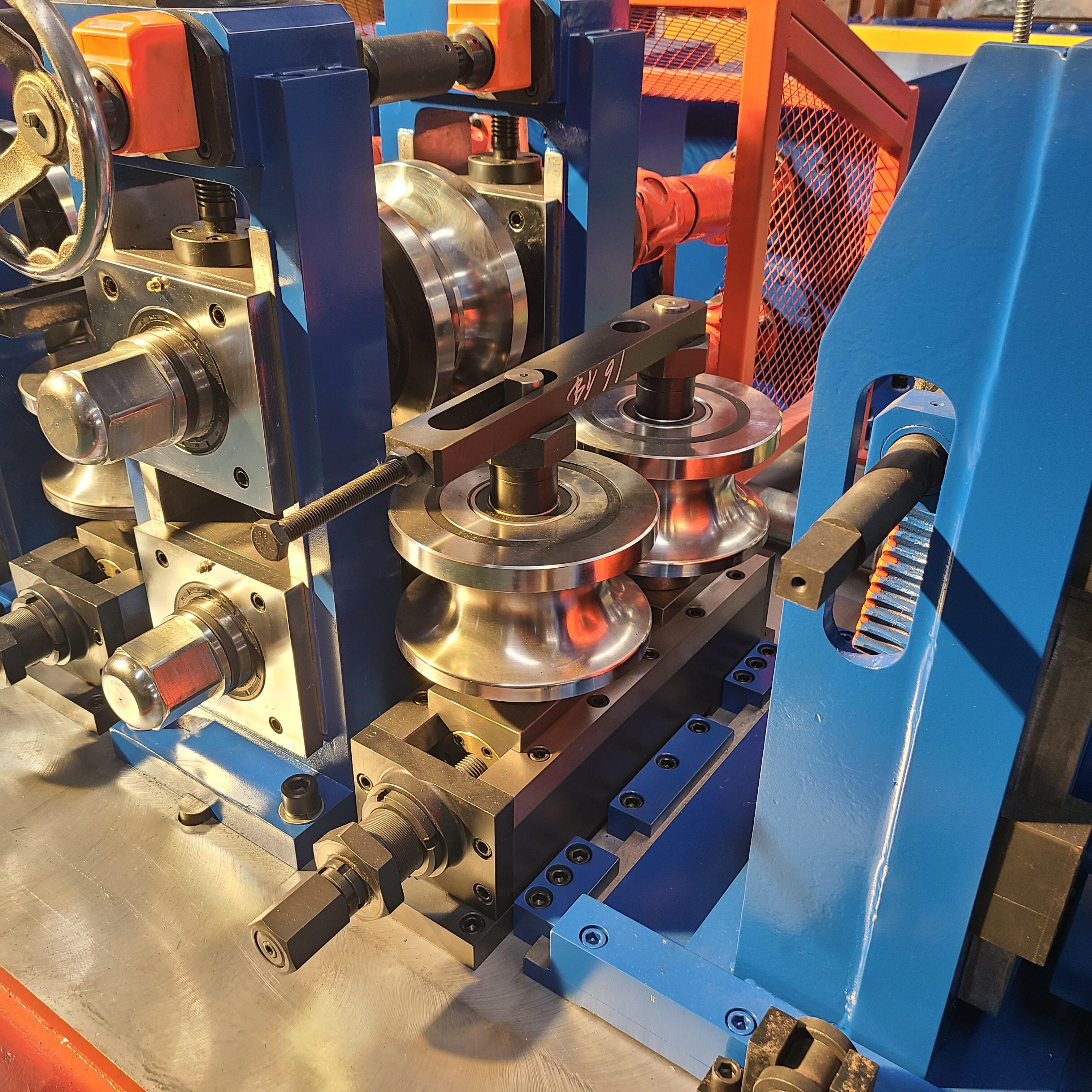

Maszyna do formowania rur stalowych reprezentuje zaawansowane rozwiązanie produkcyjne, zaprojektowane do przekształcania płaskich stalowych taśm w precyzyjne produkty rurowate za pomocą ciągłego procesu wałkowania. To zaawansowane urządzenie wykorzystuje serię zestawów wałków, które stopniowo kształtują materiał do pożądanego profilu okrągłego, kwadratowego lub prostokątnego. Maszyna integruje wiele etapów, w tym podawania taśmy, przygotowywania krawędzi, formowania, spawania i operacji kalibrowania. Jej nowoczesne systemy sterowania gwarantują stałą dokładność wymiarową i wysokiej jakości spawanie przez cały cykl produkcji. Technologia obejmuje zaawansowane funkcje, takie jak automatyczna korekta szerokości, precyzyjne kontrolowanie temperatury podczas spawania oraz systemy monitoringu w czasie rzeczywistym, które utrzymują jakość produktu. Te maszyny są w stanie produkować rury o zmiennych średnicach, od małych do dużych rozmiarów przemysłowych, z grubością ścianki zmieniającą się zgodnie z wymaganiami aplikacji. Wielofunkcyjność maszyn do formowania rur stalowych czyni je kluczowymi w różnych przemyślach, w tym budowlanym, samochodowym, produkcji mebli i rozwijaniu infrastruktury. Wykonują się świetnie w sytuacjach-produkcyjnych dużych objętości, zachowując jednocześnie elastyczność dostosowywania do różnych specyfikacji produktów i klas materiałów.