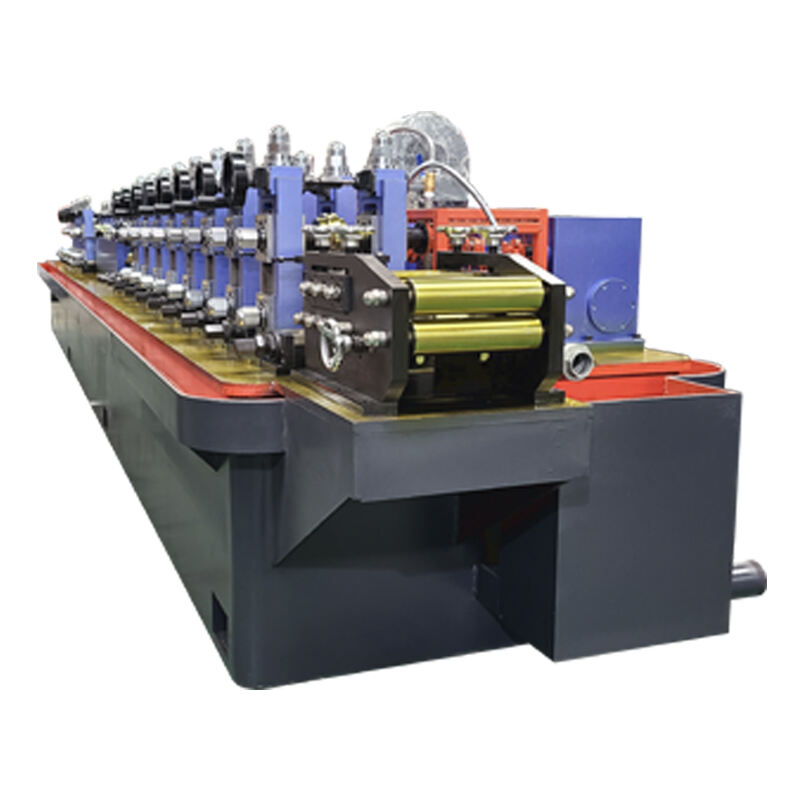

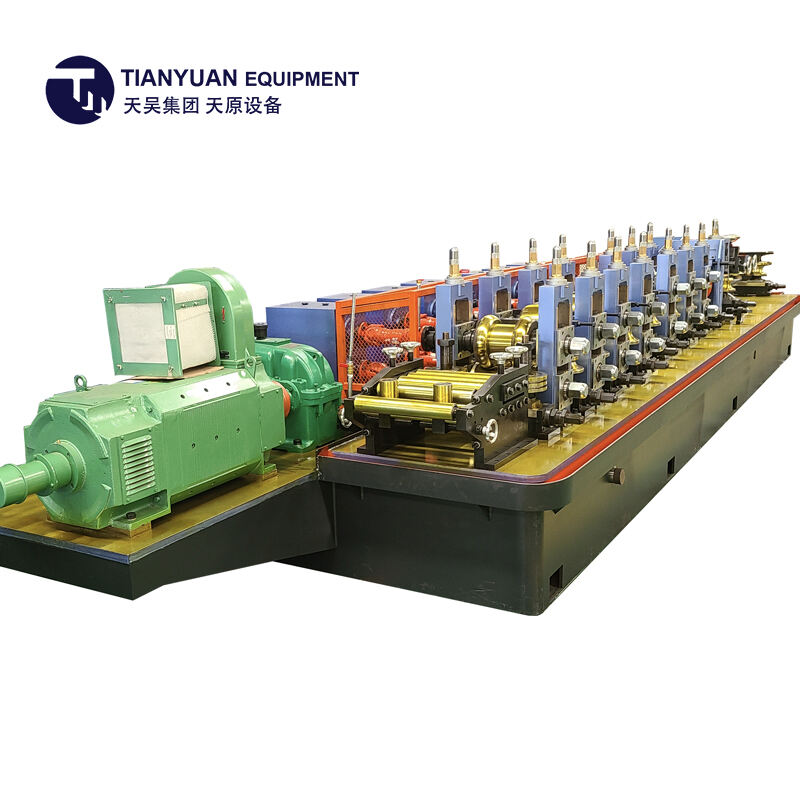

máquina de fabricação de tubos gi eficiente

A eficiente máquina de fabricação de tubos GI representa uma revolução na tecnologia moderna de fabricação de tubos, oferecendo uma solução abrangente para a produção de tubos de ferro galvanizado de alta qualidade. Este sistema avançado integra múltiplos processos, incluindo desbobinamento, formação, soldagem, dimensionamento e operações de corte em uma linha de produção contínua. A máquina utiliza sistemas hidráulicos de controle de precisão e tecnologia avançada de soldagem para garantir um diâmetro de tubo consistente e espessura de parede durante todo o processo de produção. Com velocidades de produção que podem chegar a até 50 metros por minuto, esta máquina melhora significativamente a eficiência de fabricação enquanto mantém padrões de qualidade superiores. O sistema possui controles automatizados com interfaces de tela sensível ao toque, permitindo que os operadores monitorem e ajustem parâmetros em tempo real. Sua construção robusta incorpora componentes de aço industrial, garantindo durabilidade e confiabilidade de longo prazo. A máquina pode acomodar várias especificações de tubos, normalmente manipulando diâmetros de 15mm a 165mm com espessuras de parede variando de 1,5mm a 5mm. Recursos avançados de segurança incluem sistemas de parada de emergência, detecção automática de falhas e guarda-protectores ao redor dos componentes móveis. O design modular da máquina facilita a manutenção fácil e a substituição rápida de componentes, minimizando o tempo de inatividade da produção.