máquina de formação de tubos de manutenção simples

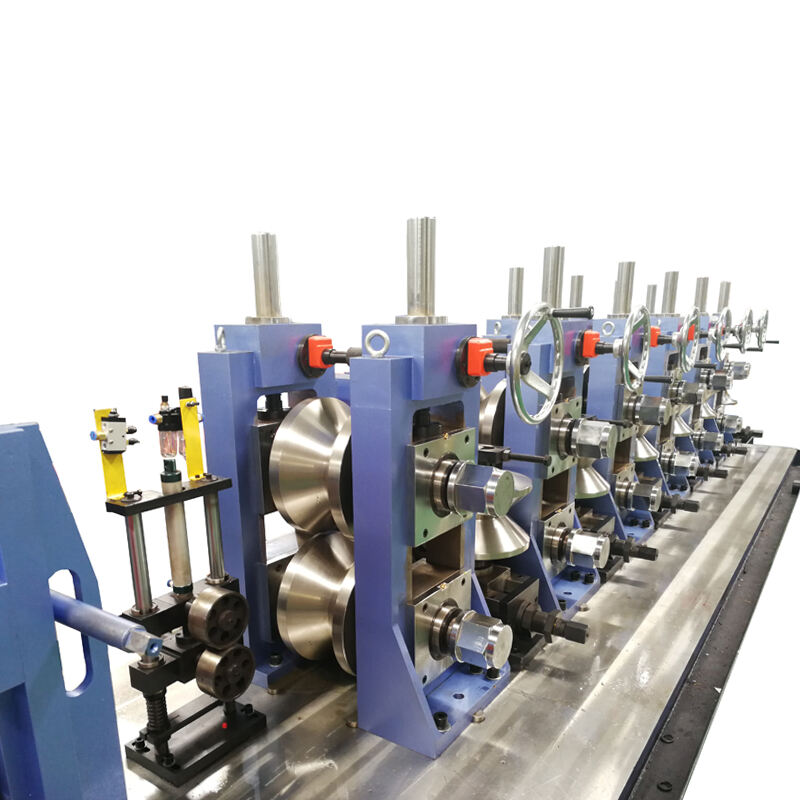

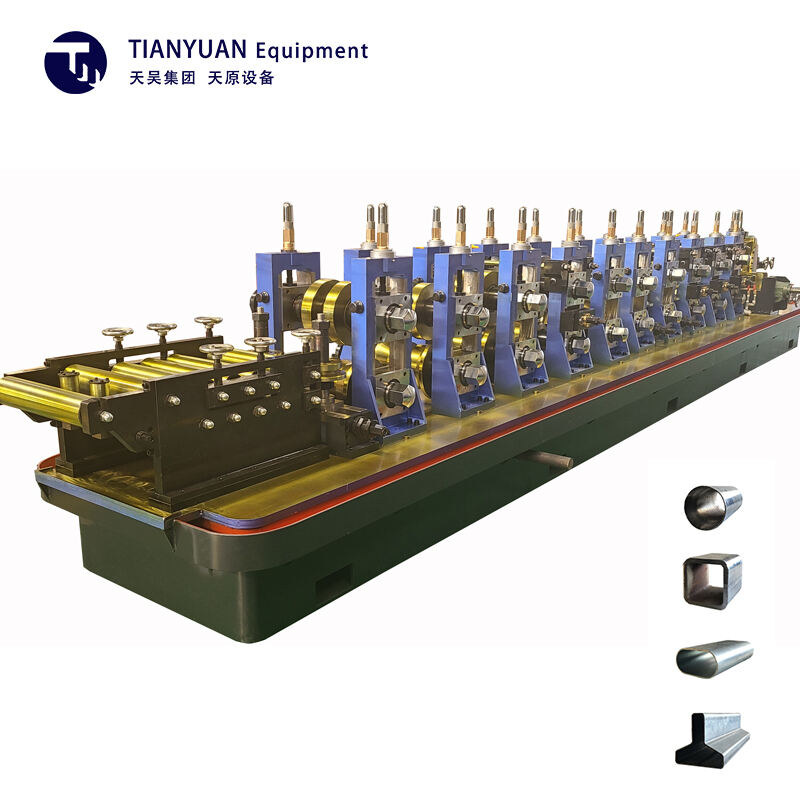

A simples máquina de formação de tubos de manutenção representa uma avanço revolucionário na tecnologia de fabricação industrial de tubos. Este equipamento versátil transforma eficientemente chapas metálicas planas em tubos precisamente formados por meio de um processo sistemático de rolagem e soldagem. A máquina incorpora recursos avançados de automação que simplificam o fluxo de produção, permitindo uma qualidade de saída consistente enquanto minimizam a intervenção do operador. Seu design robusto inclui rolos de formação ajustáveis que acomodam vários diâmetros e espessuras de tubos, tornando-a adequada para diferentes requisitos de fabricação. O sistema de controle da máquina oferece operação intuitiva através de uma interface amigável, permitindo que os operadores ajustem facilmente parâmetros como velocidade de formação, pressão e alinhamento. Recursos tecnológicos principais incluem estações de formação projetadas com precisão, mecanismos automáticos de alimentação de material e sistemas integrados de controle de qualidade que garantem precisão dimensional durante todo o processo de produção. A máquina se destaca em aplicações que variam de projetos de construção e infraestrutura a sistemas de HVAC e soluções de tubulação industrial. Sua construção modular facilita mudanças rápidas de ferramentas e procedimentos de manutenção, maximizando a eficiência operacional e reduzindo o tempo de inatividade. O sistema também incorpora recursos de segurança, como mecanismos de parada de emergência e guarda-protectores, garantindo a segurança do operador enquanto mantém a produtividade.