простой в обслуживании hf сварочный станок для труб

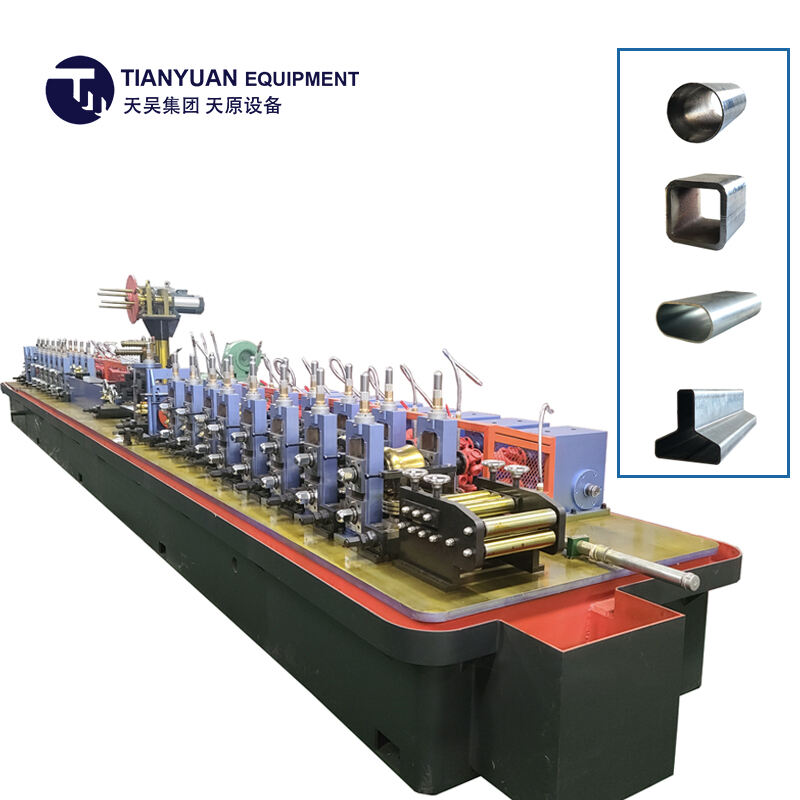

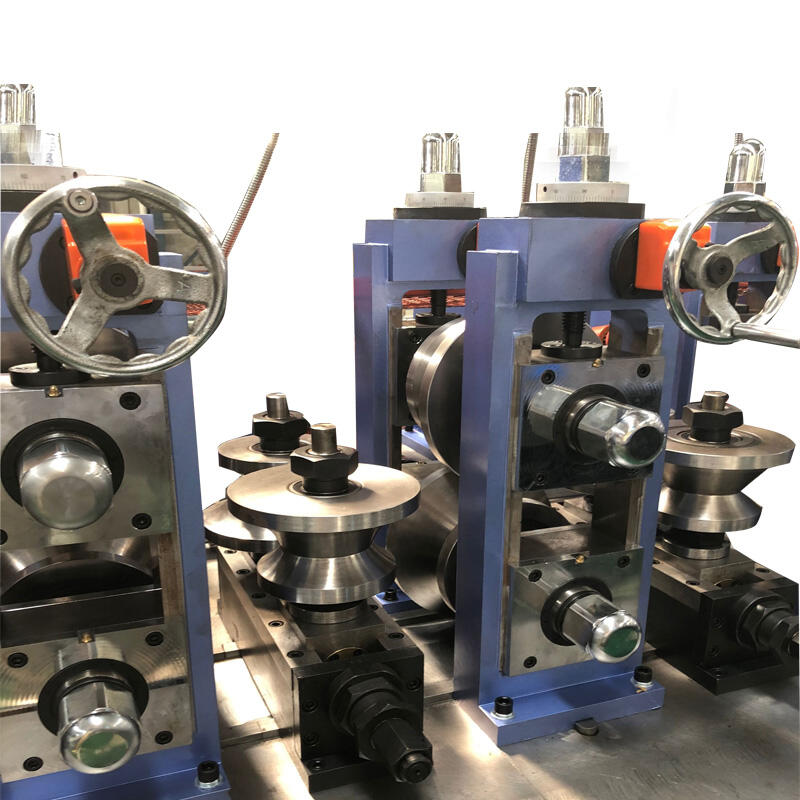

Легко обслуживаемая HF сварочная трубная мельница представляет собой передовое решение в современной технологии производства труб. Этот продвинутый системный подход сочетает точное инженерное исполнение с удобным для пользователя дизайном, что позволяет эффективно и последовательно производить высококачественные сварные трубы. Мельница функционирует через сложный процесс высокочастотной сварки, где металлические полосы формируются, свариваются и доводятся до кондиции на непрерывной линии производства. Ключевые технологические особенности включают автоматизированные механизмы подачи полос, точные формующие станции, передовые HF-сварочные узлы и интегрированные системы контроля качества. Дизайн мельницы подчеркивает доступность для обслуживания, с модульными компонентами, которые можно легко проверять и обслуживать. Она адаптируется к различным спецификациям труб, обычно производя трубы диаметром от 20 мм до 165 мм, с толщиной стенки от 1,2 мм до 6 мм. Система включает в себя технологию умного мониторинга, которая отслеживает параметры производства в реальном времени, обеспечивая постоянное качество сварных швов и точность размеров. Области применения охватывают множество отраслей, включая строительство, автомобилестроение, производство мебели и сельскохозяйственного оборудования. Versatility мельницы позволяет быстро менять размеры и типы материалов, делая её подходящей как для массового производства, так и для специализированных заказов.