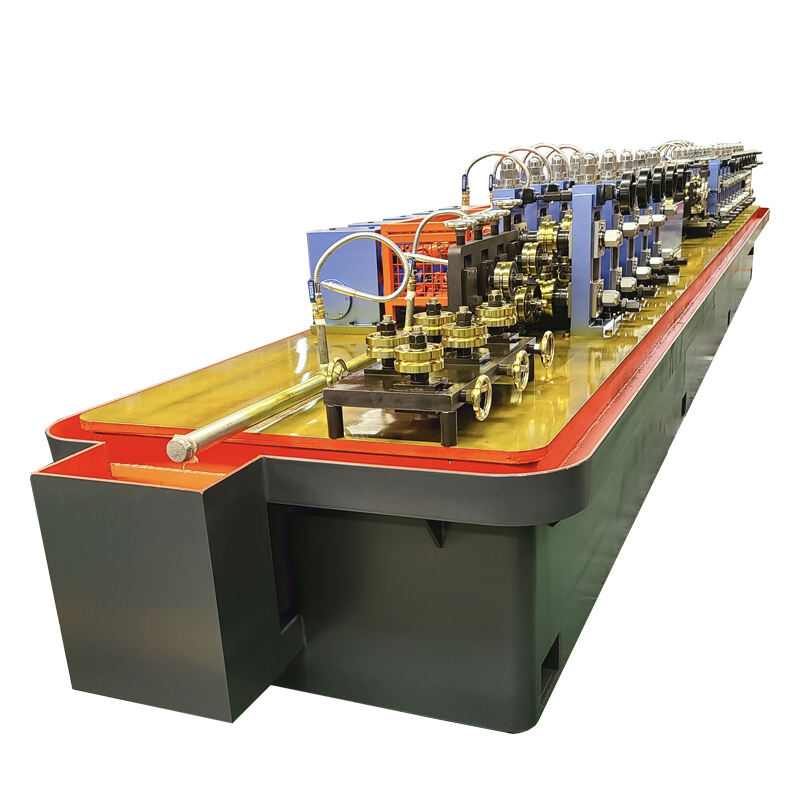

najnovšia strojová linka na výrobu potrubí z galvanizovaného železa

Najnovšia strojová jednotka na výrobu GI rúr predstavuje významný pokrok v technológii výroby rúr, ktorá ponúka neprecedentnú presnosť a efektivitu pri výrobe galvanizovaných železných rúr. Táto moderná zariadenie integruje systémy automatickej regulácie s pokročilou svárkovacou technológiou, čo zabezpečuje konzistentne vysokú kvalitu výstupu. Stroj obsahuje sofistikovanú formovaciu časť s viacerými valcovými stanovištmami, ktoré postupne tvarujú oceľový pás do dokonalého tubusového tvaru. Jeho vysokočastotný svárkovací systém pracuje na optimálnych frekvenciách na vytvorenie silných, rovnomerných šovov. Systém aplikácie zinečnej nátierky zahŕňa presnú kontrolu teploty a automatizované monitorovanie hrúbky, čo zabezpečuje rovnomernú galvanizáciu splňujúcu medzinárodné normy. Kapacita výroby stroja sa pohybuje od 20 do 50 metrov za minútu, podľa špecifikácií rúr, s možnosťou výroby rúr priemerom od 1/2 palca po 8 palcov. Integrovaný systém kontroly kvality používa laserovú meraciu technológiu a detekciu defektov v reálnom čase, čo významne zníži odpad a zabezpečí konzistentnú kvalitu produkcie. Okrem toho obsahuje stroj pokročilý rezačný systém s presnosťou nastavenia dĺžky do 0,5 mm, čo ho robí ideálnym pre štandardné aj vlastné požiadavky na dĺžku.