dobavljači mašina za proizvodnju automobilske cevi

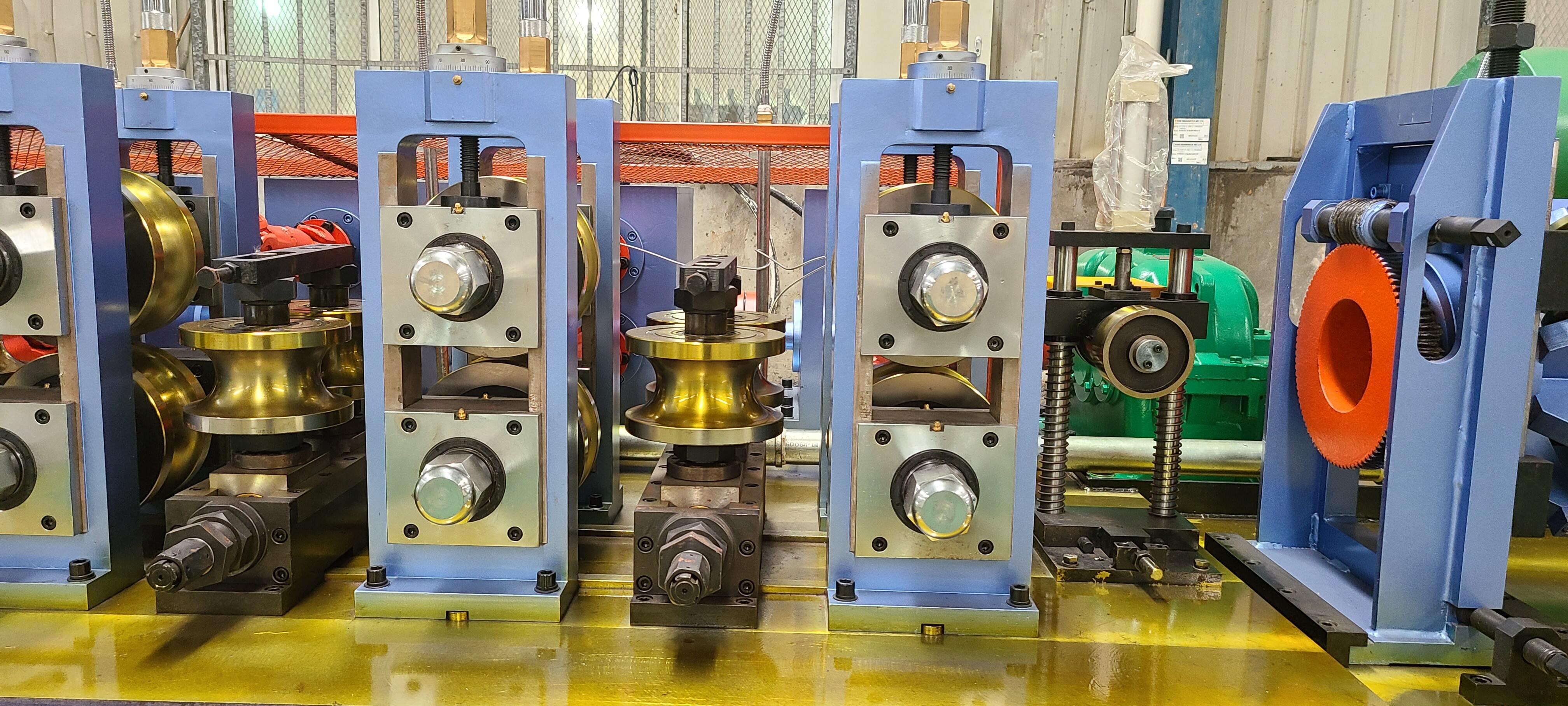

Dobavljači mašina za proizvodnju automobilskih cevi predstavljaju ključni deo u automobilskoj proizvodnoj industriji, pružajući osnovnu opremu za izradu visokopreciznih cevi i tubinskih komponenti. Ovi dobavljači nude sofisticirane mašine koje kombinuju naprednu automatizaciju, precizne kontrolne sisteme i čvrste proizvodne mogućnosti. Mašine koje pružaju su dizajnirane da rade sa različitim materijalima, uključujući ocel, aluminijum i bakar, proizvodeći cevi po tačnim specifikacijama za automobilsku upotrebu. Ovi sistemi obično imaju računarske kontrolne interfejs, više formiranja stanica i mehanizme za proveru kvaliteta kako bi se osigurala konzistentna izlazna proizvodnja. Mašinerija može da proizvede cevi koje se šire od gorivnih linija do isparivačkih sistema, sa mogućnostima za različite prečnike, debljinu zida i konfiguracije. Savremene mašine za proizvodnju automobilskih cevi uključuju sisteme za stvarno vreme praćenja, automatizovane mehanizme za unos materijala i precizne tehnologije reza. Takođe poseduju napredne mogućnosti varanja, uključujući TIG, MIG i laser varanje opcije, osiguravajući visoku kvalitetu formiranja jaha. Dobavljači često nude kompleksna rešenja koja uključuju ne samo osnovnu mašineriju, već i pomoćnu opremu kao što su sistemi za raspoređivanje, ravnanje jedinice i rešenja za pakovanje. Ove mašine su dizajnirane sa naglaskom na energetsku učinkovitost, smanjenje otpada materijala i optimizovane brzine proizvodnje, čime postaju neocenjive imovine u operacijama automobilskog proizvodnja.