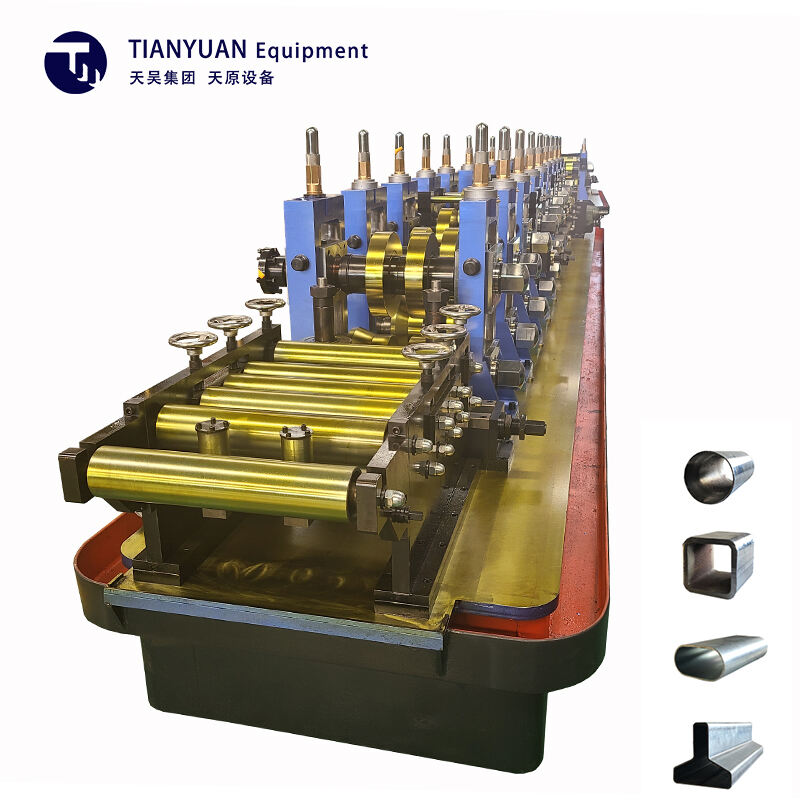

เครื่องทำท่อราคาถูก

เครื่องทำท่อราคาถูกเป็นทางเลือกที่คุ้มค่าสำหรับความต้องการในการผลิตหลากหลายในอุตสาหกรรมการแปรรูปโลหะ เครื่องมือที่หลากหลายนี้สามารถเปลี่ยนแผ่นโลหะแบนให้กลายเป็นท่อและท่อที่มีรูปร่างแม่นยำผ่านกระบวนการกลิ้งที่เป็นระบบ เครื่องจักรนี้มีโครงสร้างที่แข็งแรงพร้อมด้วยสถานีการแปรรูปหลายแห่ง แต่ละแห่งมีล้อกลิ้งเฉพาะที่ช่วยให้วัสดุค่อยๆ มีรูปร่างตามที่ต้องการ การทำงานเริ่มจากการโหลดแผ่นโลหะ จากนั้นเข้าสู่ขั้นตอนการแปรรูปแบบค่อยเป็นค่อยไป เช่น การเตรียมขอบ การงอเบื้องต้น และการสร้างรูปแบบสุดท้าย เครื่องจักรนี้รวมระบบการปรับเทียบขั้นสูงเพื่อให้มั่นใจว่ามีความแม่นยำของขนาดอย่างสม่ำเสมอและคุณภาพของการเชื่อมที่ยอดเยี่ยม ออกแบบมาสำหรับการดำเนินงานขนาดเล็กและปริมาณการผลิตระดับกลาง รองรับความหนาของวัสดุหลากหลายและสามารถผลิตท่อได้ตั้งแต่เส้นผ่านศูนย์กลาง 20 มม. ถึง 76 มม. การรวมฟีเจอร์อัตโนมัติพื้นฐานช่วยรักษาอัตราการผลิตที่คงที่ขณะลดการแทรกแซงของผู้ปฏิบัติงาน ระบบควบคุมที่ใช้งานง่ายของเครื่องจักรช่วยให้ปรับพารามิเตอร์ได้อย่างรวดเร็วและสะดวกต่อการใช้งาน ทำให้เหมาะสมสำหรับผู้ปฏิบัติงานที่มีประสบการณ์แตกต่างกัน การประยุกต์ใช้งานครอบคลุมหลายอุตสาหกรรม เช่น การผลิตเฟอร์นิเจอร์ การก่อสร้าง อุปกรณ์ทางการเกษตร และโครงการแปรรูปโลหะทั่วไป