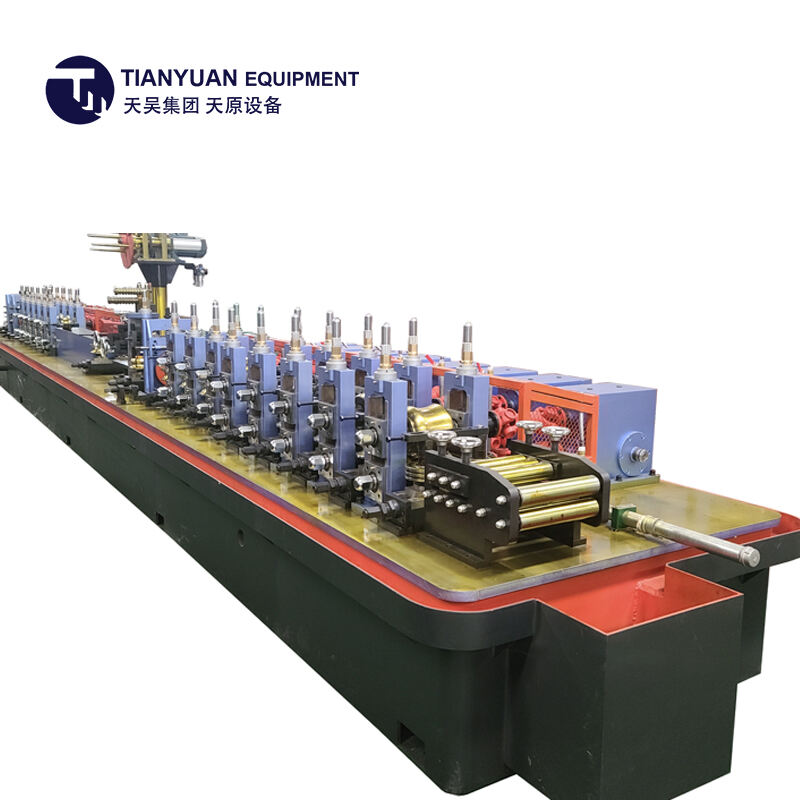

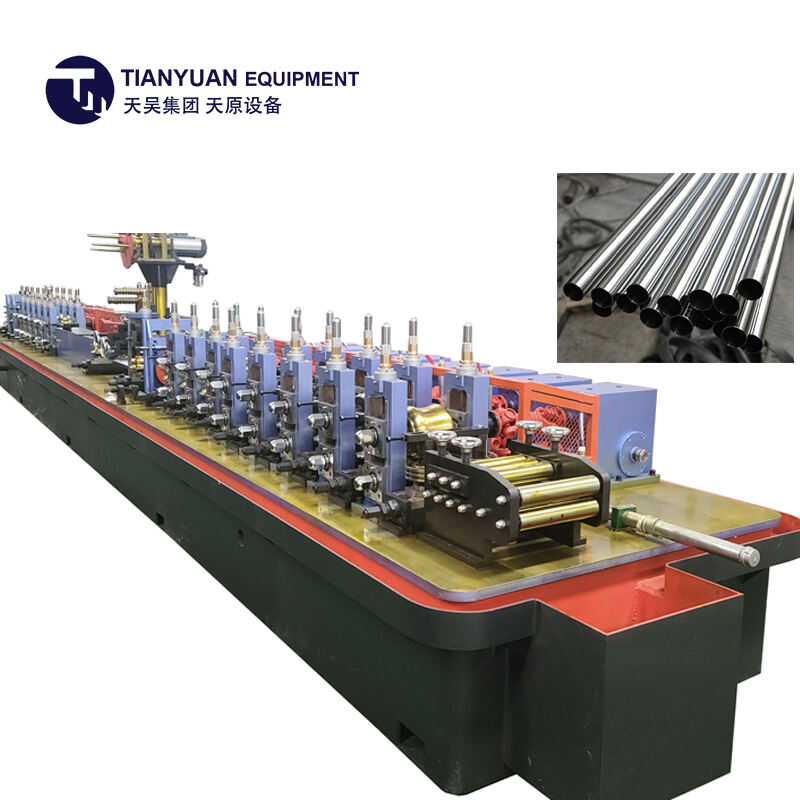

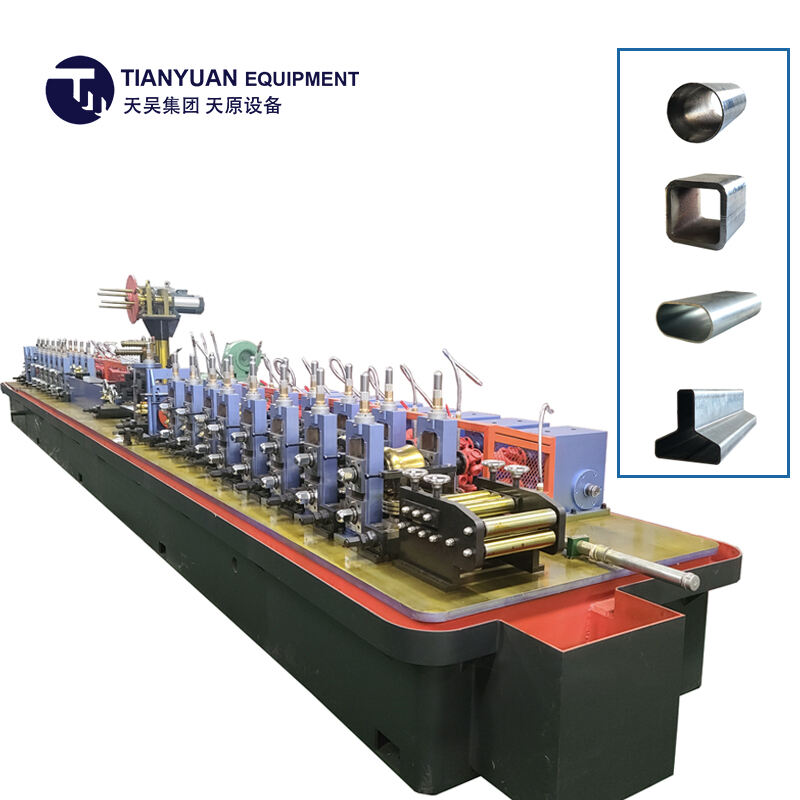

china carbon steel pipe making machine

Ang makina para sa paggawa ng tubo ng carbon steel mula sa Tsina ay kinakatawan bilang isang masusing solusyon sa paggawa na disenyo upang magbigay ng mataas na kalidad ng mga tubo ng carbon steel na may katatagan at ekadensiya. Ang unang ehemplo na aparato na ito ay sumasama sa pinakabagong teknolohiya upang tugunan ang patuloy na produksyon ng mga tubo ng bakal sa pamamagitan ng isang saksak na kontroladong proseso ng pagsasaak, pagtutulak, at pagpapabuti. Gumagamit ang makina ng masusing teknolohiya ng roll forming upang hugisain ang patpat na strips ng bakal sa siklikong anyo, kasunod ng high-frequency welding upang lumikha ng walang sundang kumpanya. Ang sistema ay may mga automatikong kontrol na panatilihin ang konsistente na sukat ng tubo, kapal ng dingding, at kalidad ng ibabaw sa buong proseso ng produksyon. Sa kakayahang makaprodukta ng mga tubo na mula 20mm hanggang 219mm sa diyametro, ang mapagpalayuang makina na ito ay maaaring tugunan ang mga iba't ibang industriyal na pangangailangan. Kasama sa kagamitan ang maraming estasyon para sa kontrol ng kalidad, kabilang ang ultrasonic testing at hydrostatic pressure testing, na nagpapatibay na bawat tubo ay nakakamit ang pandaigdigang mga standard. Ang linya ng produksyon ay na-equip sa isang automatikong sistema ng paghahandle sa material, bumababa ang manual na pakikipag-udyok at nagpapabuti sa seguridad ng operasyon. Ang makina na ito ay partikular na maayos para sa paggawa ng mga tubo na ginagamit sa konstruksyon, transportasyon ng langis at gas, at iba't ibang industriyal na aplikasyon.