hf svarkalangan qurilma milli yetkazib beruvchilari

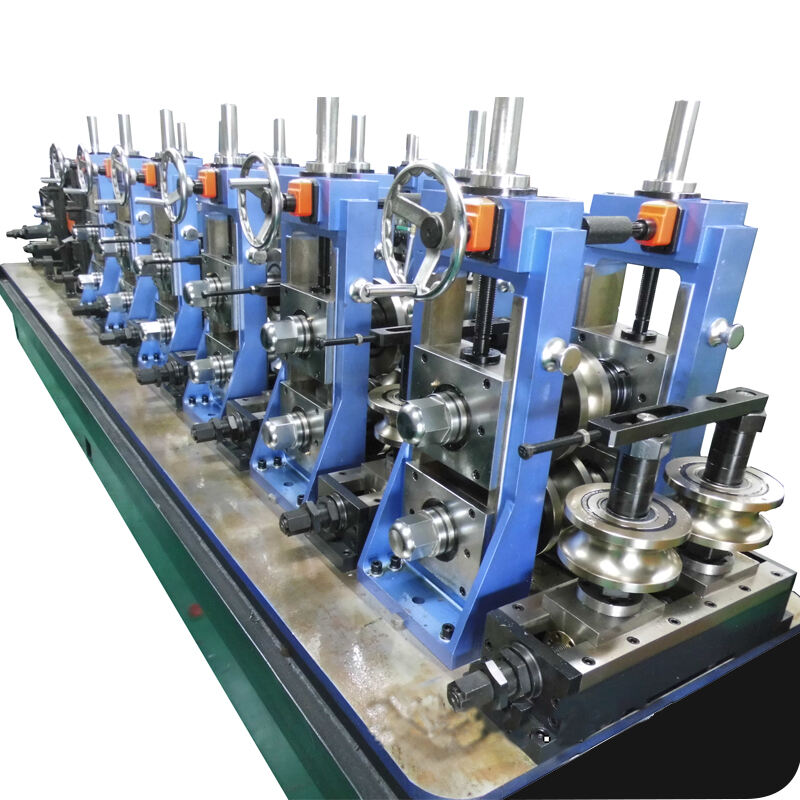

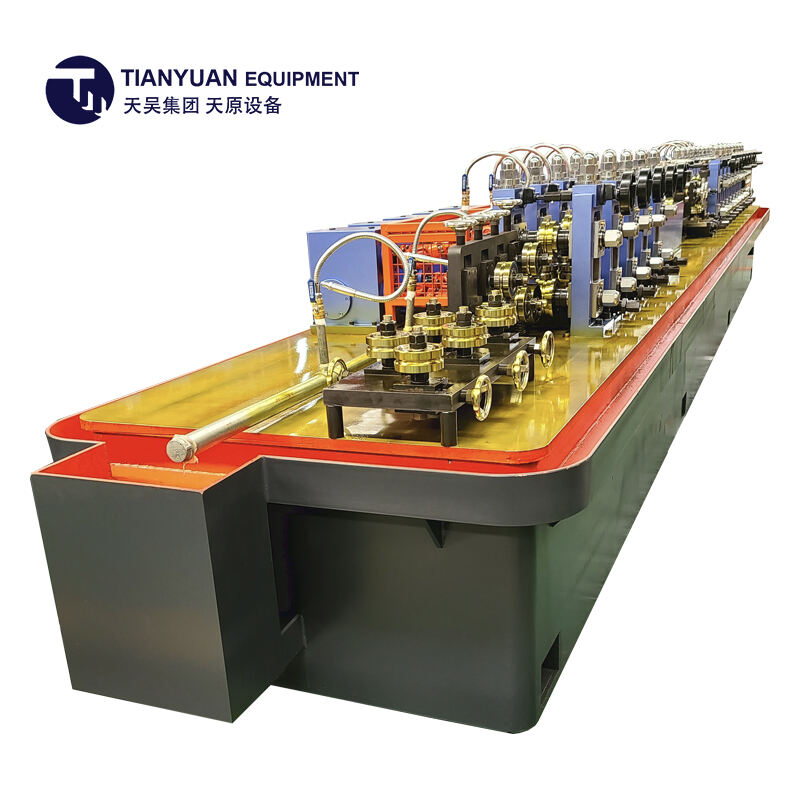

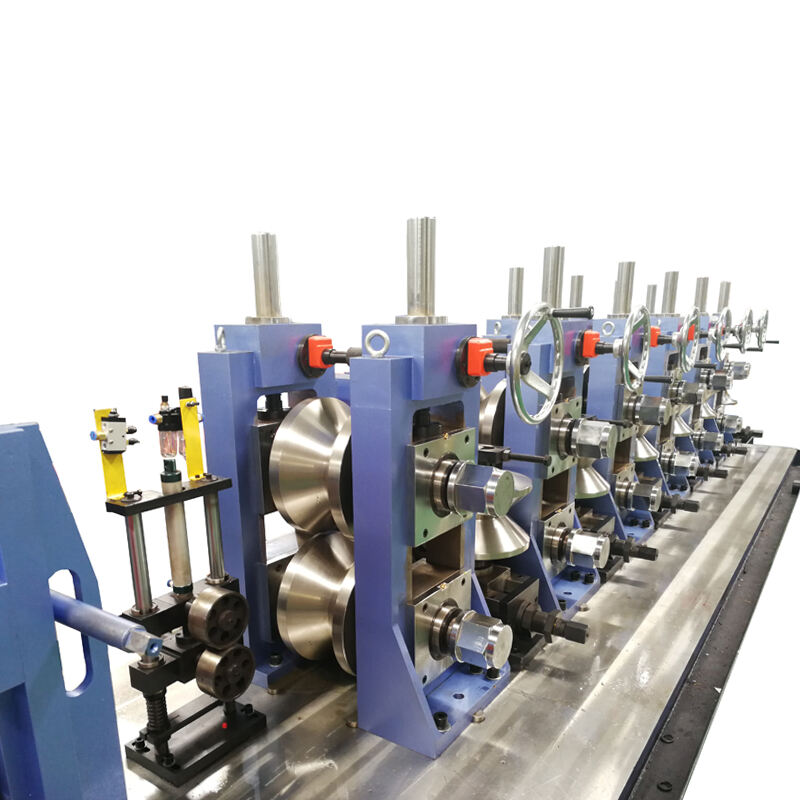

HF zvarlangan qalin mill yetkazib beruvchilari sanoat ishlab chiqarish sohasida muhim o'yinchi hisoblanadi, keng tarqalgan zvarlangan qalin ishlab chiqarish uskunasi bo'yicha ishlab chiqarish va distributsiya sohasida mutaxassislik ko'rsatadi. Ushbu yetkazib beruvchilar modern keng tarqalgan zvar texnologiyasi orqali zvarlangan tomir qalinlarni ishlab chiqarish uchun umumiy yechimlar taklif qiladi. Ularga taqdim etilgan uskunalar oddiy shakllarda tizimlar, zvar stansiyalari, o'lcham berish stantsiyalari va kesish uskunalari kabi barcha birikib turib butun ishlab chiqarish to'garoqini tashkil etadi. Modern HF zvarlangan qalin milllari asosan aniqlik zvar parametrlarini ta'minlash va ishlab chiqarish jarayonida muvofiq sifatni saqlash uchun murakkab boshqaruvi tizimlaridan foydalanadi. Ushbu yetkazib beruvchilar faqat uskunani taqdim etadi balki texnik yordam, xizmatlar bilan mustahkamlash va maxsus ishlab chiqarish talablari bilan urinish uchun moslashtirish variantlarini ham taklif qiladi. Uslublari kichik diametrli qalinlar dan boshlab katta miqdordagi sanoat qalinlariga qadar har qanday muammolar uchun qulay, shu jumladan qurilish, nafta va gaz transporti va struktural inzheneriyaga qaraganda. Ushbu milllarda ishlatiladigan texnologiya baland ishlab chiqarish effektivligini, kamaytirilgan material ishlaydi va klassik zvar usullaridan yaxshi zvar sifati haqida himoyalaydi.