ishonchli ugriy qanday oʻlchovdagi cheloyak asosida kanal quruvchi mashinasi

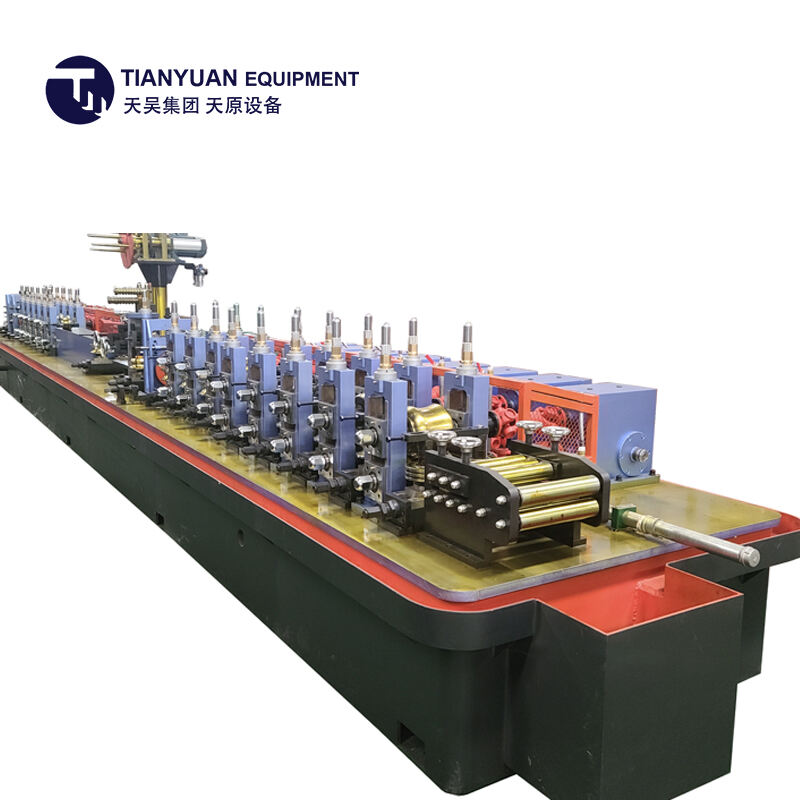

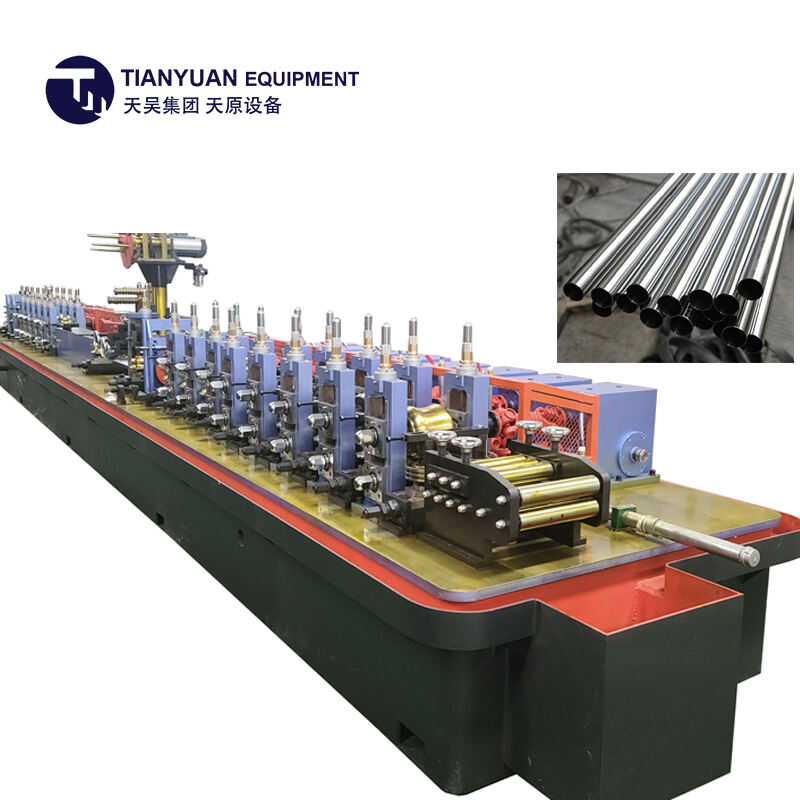

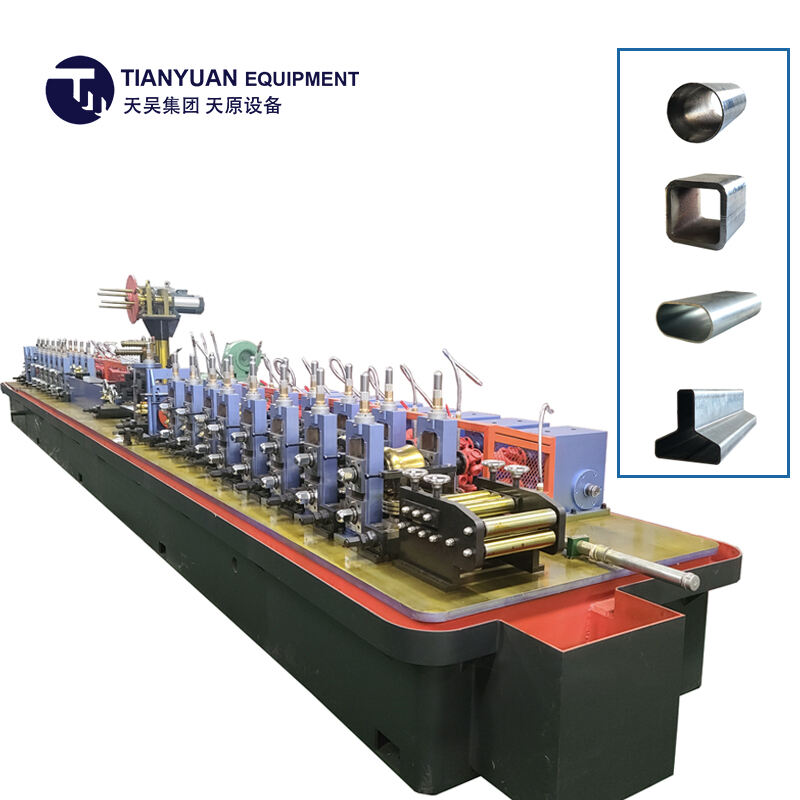

Isroliy va qadrligi bilan ishlaydigan ugriy sabz metal borliq borliq qurilish mashini, sanoatda o'zgaruvchan yechimni taqdim etadi, to'g'ri va tezlik bilan yetarlicha sifatli ugriy sabz metal borliqlarni ishlab chiqarish uchun mo'ljallangan. Ushbu sovrin texnika ko'p asosiy jarayonlarni birlashtiradi, shu jumladan, material berish, suratga keltirish, zudlash va yakuniy holatga keltirish, barchasi bir dona avtomatik ishlab chiqarish chizig'ida. Mashinaning sof mukammal baland chastotali zudlash texnologiyasidan foydalanib, yakuniy borliqlarning zudlanishi sifati va struktural integriteti juda yaxshi bo'ladi. U sofistikatsiya kontrol tizimlariga va PLC avtomatizatsiyasiga ega, shuning uchun formalar tezligi, zudlash harorati va kesish uzunligi kabi parametrlar to'g'ri sazlanadi. Texnikada turli metall darajalari va divar qalinligi bilan ishlash mumkin, diametr 20mm dan 219mm gacha borliqlarni ishlab chiqaradi. Robust konstruksiya va davranishga qaraganda dizaynlangan mashina, muvaffaqiyatli ish faoliyatini muhim ishlab chiqarish davom ettiradi. Tizim to'liq sifatni tekshirish mekanizmlariga ega, haqiqiy vaqtning monitoringi va avtomatik defekt aniqlash imkoniyatlari orqali. Ushbu mashina qurilish, nafta va gaz transporti, xodimlik suvi ajratish va umumiy sanoat suv transport tizimlari kabi bir necha sanoatda ishlatiladi. Mashina modulli dizayni orqali turli xil borliq speksifikatsiyalari orasida oson xavfsiz va tez almashtirishni ta'minlaydi, operatsion effektivlikni maksimallashtiradi va davom etishni kamaytiradi.