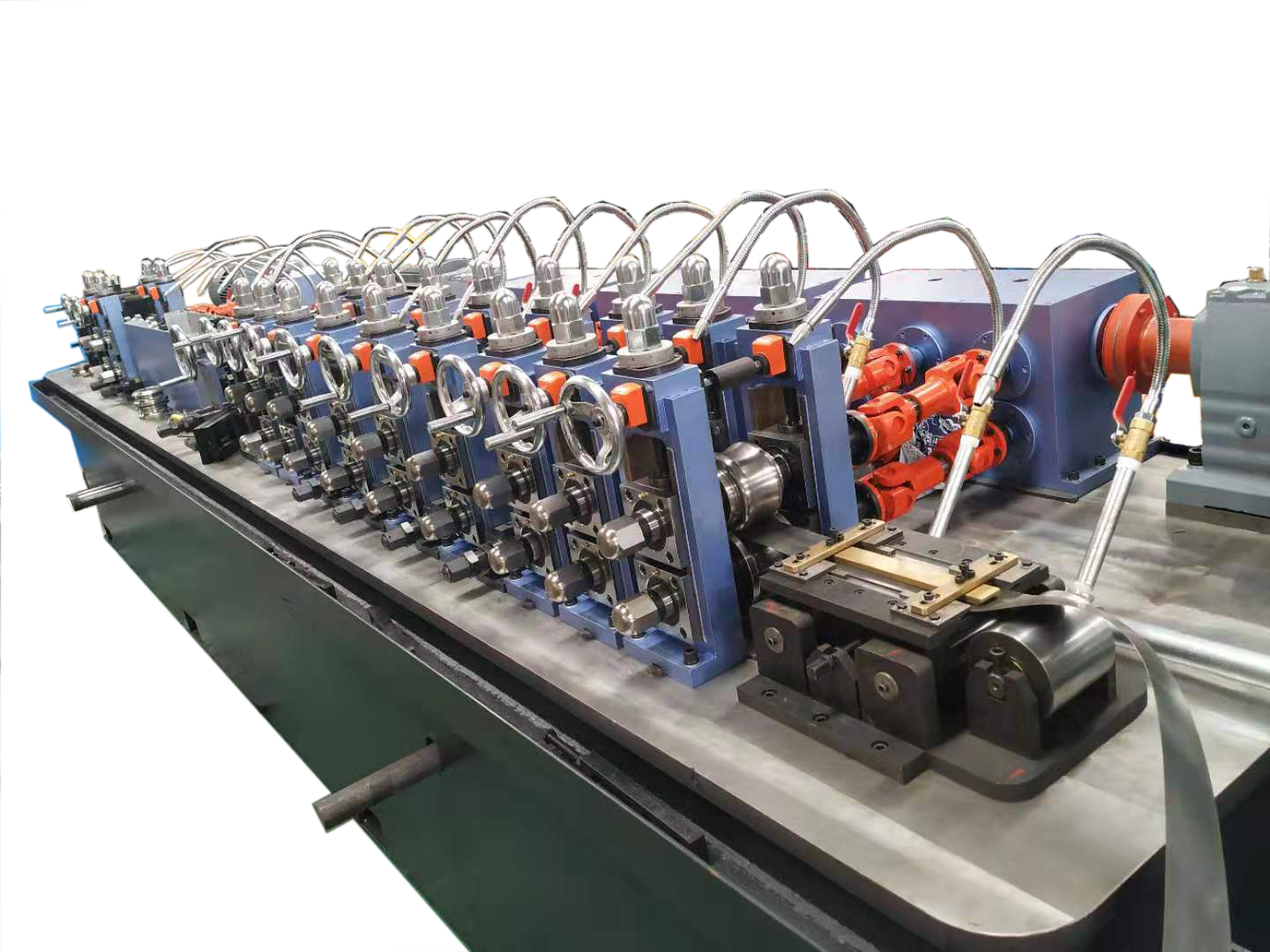

máy làm ống gi tiên tiến

Máy làm ống GI tiên tiến đại diện cho một giải pháp hiện đại trong công nghệ sản xuất ống ngày nay. Thiết bị tinh vi này hiệu quả trong việc sản xuất các ống thép mạ kẽm thông qua quy trình tối ưu hóa, kết hợp kỹ thuật chính xác với điều khiển tự động. Máy có dây chuyền sản xuất toàn diện bao gồm các trạm mở cuộn, tạo hình, hàn, định cỡ và hoàn thiện. Hệ thống hàn tần số cao của máy đảm bảo chất lượng đường hàn vượt trội, trong khi hệ thống điều khiển tiên tiến duy trì kích thước ống nhất quán trong suốt quá trình sản xuất. Máy có thể xử lý nhiều thông số ống khác nhau, thường sản xuất các ống có đường kính từ 15mm đến 165mm, với độ dày thành từ 1.0mm đến 4.5mm. Hệ thống mạ kẽm tích hợp áp dụng lớp phủ kẽm đồng đều, cung cấp khả năng chống ăn mòn tuyệt vời cho sản phẩm hoàn thiện. Các tính năng công nghệ nổi bật bao gồm điều chỉnh chiều rộng tự động, giám sát hàn thời gian thực và cơ chế cắt chính xác. Ứng dụng của máy trải rộng qua nhiều ngành công nghiệp, bao gồm xây dựng, cung cấp nước, phân phối khí gas và kỹ thuật cấu trúc. Hệ thống điều khiển PLC của máy cho phép điều chỉnh và theo dõi tham số chính xác, đảm bảo chất lượng sản phẩm đạt tiêu chuẩn quốc tế. Thiết kế mô-đun của máy giúp dễ dàng bảo trì và thay đổi kích thước nhanh chóng, tối đa hóa hiệu suất hoạt động và giảm thiểu thời gian ngừng hoạt động. Tốc độ sản xuất có thể đạt tới 40 mét mỗi phút, tùy thuộc vào thông số ống và đặc tính vật liệu.