buy steel pipe making machine

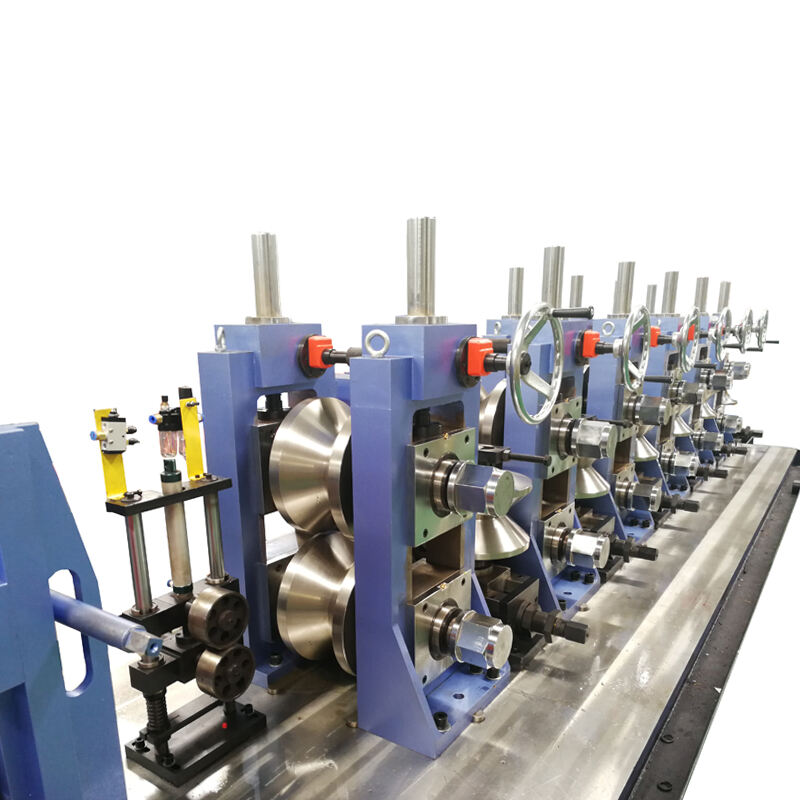

The steel pipe making machine represents a significant advancement in industrial manufacturing technology, offering a comprehensive solution for producing high-quality steel pipes efficiently and consistently. This sophisticated equipment incorporates advanced automation systems and precise control mechanisms to transform raw steel materials into perfectly formed pipes suitable for various applications. The machine features multiple processing stations, including uncoiling, forming, welding, sizing, and cutting units, all working in perfect synchronization. Its robust construction ensures long-term durability while maintaining precise dimensional accuracy throughout the production process. The machine can handle different steel grades and thicknesses, typically ranging from 0.5mm to 3mm, and can produce pipes with diameters from 12mm to 76mm. Advanced welding technology, including high-frequency welding systems, ensures strong and reliable seam quality. The integrated quality control systems continuously monitor production parameters, including welding temperature, forming accuracy, and surface finish, guaranteeing consistent product quality. This machine is particularly valuable for industries requiring large-scale pipe production, such as construction, automotive, furniture manufacturing, and infrastructure development projects.