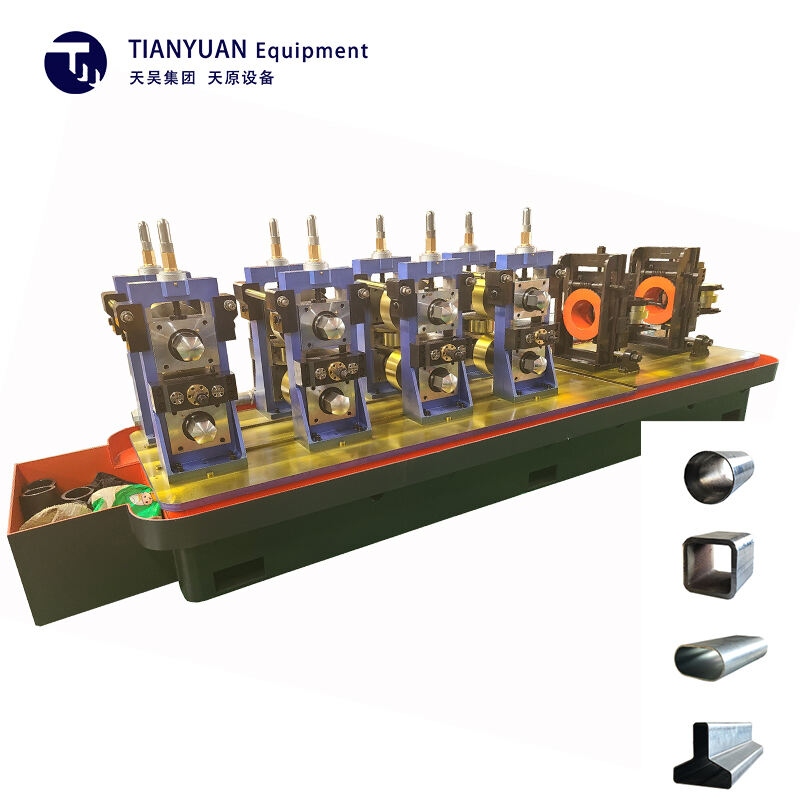

erw tube mill manufacturers

ERW tube mill manufacturers are specialized industrial entities that design, produce, and supply high-precision equipment for manufacturing Electric Resistance Welded (ERW) tubes. These manufacturers create sophisticated production lines that transform flat steel strips into welded tubes through a continuous, automated process. Their mills incorporate advanced technologies including precision forming stations, high-frequency welding systems, and automated quality control mechanisms. Modern ERW tube mill equipment features computer-controlled operations, enabling precise adjustments for different tube specifications and maintaining consistent production quality. These manufacturers typically offer comprehensive solutions, from entry-level systems for basic tube production to advanced mills capable of producing complex tube profiles. Their equipment incorporates features such as automatic size change systems, inline eddy current testing, and advanced cooling systems. The mills can produce tubes ranging from small diameters suitable for furniture to large pipes used in construction and infrastructure. Many manufacturers also provide after-sales support, technical training, and maintenance services to ensure optimal equipment performance and longevity.