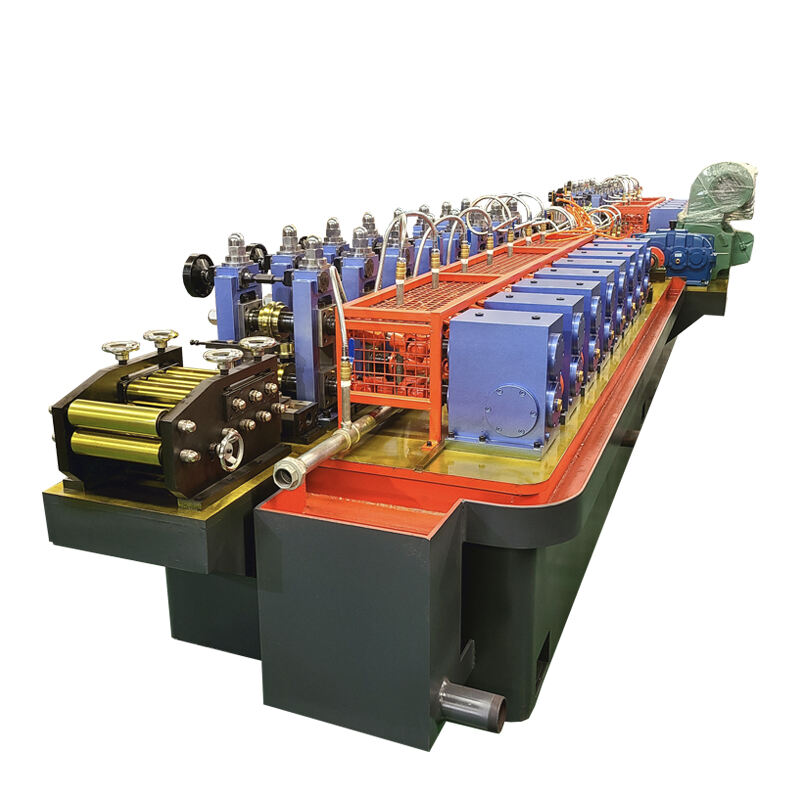

flexible operation erw tube mill

The flexible operation ERW tube mill represents a cutting-edge solution in modern pipe manufacturing technology. This advanced system combines precision engineering with versatile operational capabilities to produce high-quality welded tubes efficiently. The mill utilizes electric resistance welding (ERW) technology, which enables the continuous formation and welding of steel strips into tubes with exceptional accuracy. The system's flexible operation allows for quick size changes and adjustments, making it ideal for manufacturers who need to produce various tube specifications. Key functions include automated strip feeding, precise forming through multiple roll stands, high-frequency welding, and inline quality control systems. The mill's technological features incorporate advanced servo drives, digital control systems, and real-time monitoring capabilities that ensure consistent weld quality and dimensional accuracy. Applications span across multiple industries, including construction, automotive, furniture manufacturing, and agricultural equipment. The mill can process different material grades and thicknesses, producing tubes ranging from small diameters to larger sizes, all while maintaining strict quality standards and operational efficiency. This versatility, combined with its reliable performance and advanced automation features, makes it an essential asset for modern tube manufacturing operations.