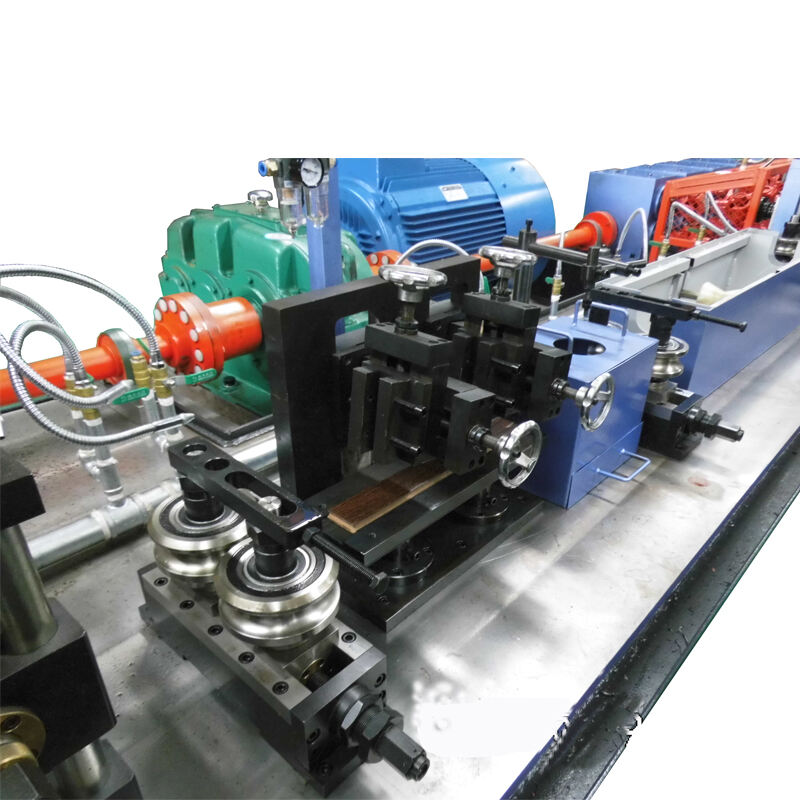

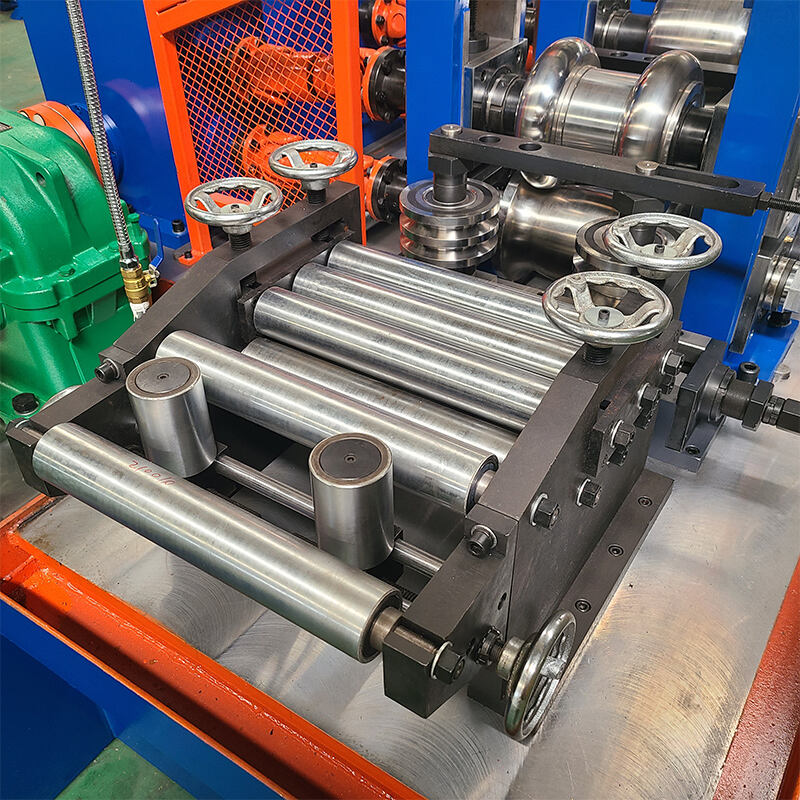

cheap erw tube mill

The cheap ERW tube mill represents a cost-effective solution for manufacturing electric resistance welded pipes and tubes. This versatile equipment employs advanced forming technology to transform flat steel strips into high-quality welded tubes through a continuous process. The mill consists of multiple forming stations that gradually shape the material, followed by high-frequency welding units that create a strong, reliable seam. Operating at speeds of up to 120m/min, these mills can produce tubes ranging from 20mm to 165mm in diameter, with wall thicknesses from 0.8mm to 6mm. The system incorporates essential components including uncoilers, strip accumulators, forming rolls, welding units, sizing stations, and cutting mechanisms. Modern cheap ERW tube mills feature automated control systems that ensure consistent product quality while minimizing material waste. The equipment is designed for optimal efficiency, requiring minimal maintenance while delivering superior production output. These mills are particularly valuable in industries such as construction, furniture manufacturing, automotive components, and general engineering applications.