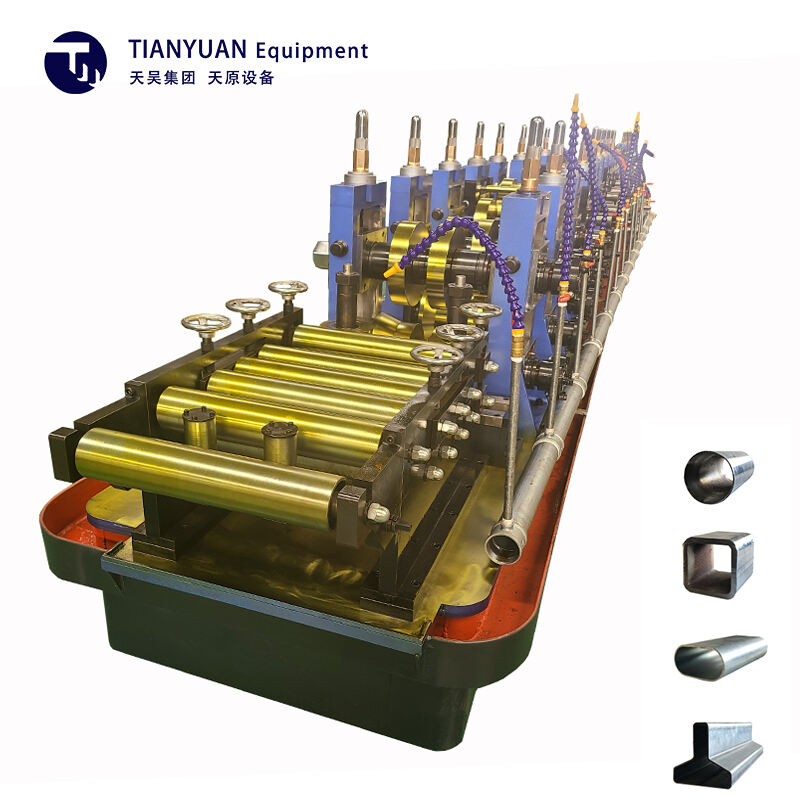

excellent performance pipe forming machine

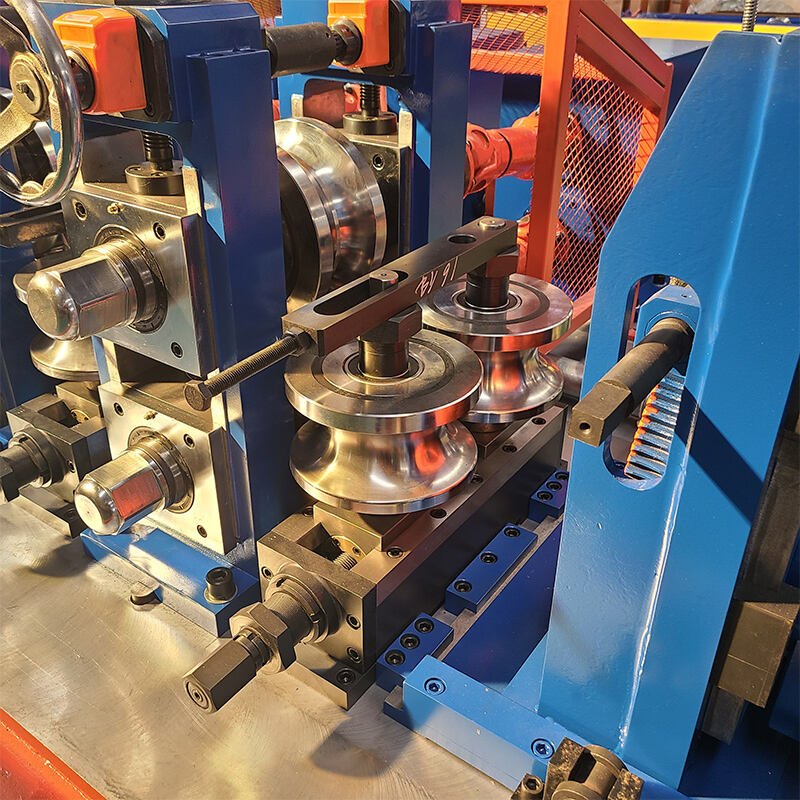

The excellent performance pipe forming machine represents a groundbreaking advancement in industrial manufacturing technology. This sophisticated equipment efficiently transforms flat metal strips into precisely formed pipes through a continuous and automated process. The machine incorporates advanced roll forming technology with multiple forming stations, each precisely calibrated to gradually shape the material into the desired tubular form. Its main functions include automatic feeding, progressive forming, precise welding, and cutting operations, all integrated into a seamless production line. The machine's technological features include digital control systems for accurate dimensional control, adjustable forming speeds up to 120m/min, and compatibility with various material thicknesses ranging from 0.5mm to 3.0mm. The equipment excels in producing both round and square pipes, with diameter capabilities from 10mm to 76mm, making it versatile for different industrial applications. The machine's robust construction ensures stability during operation, while its advanced servo motors provide precise control over the forming process. It finds extensive applications in automotive components, furniture manufacturing, construction materials, and HVAC systems. The integration of real-time monitoring systems ensures consistent quality control throughout the production process, while the automated material handling systems minimize manual intervention and increase operational efficiency.