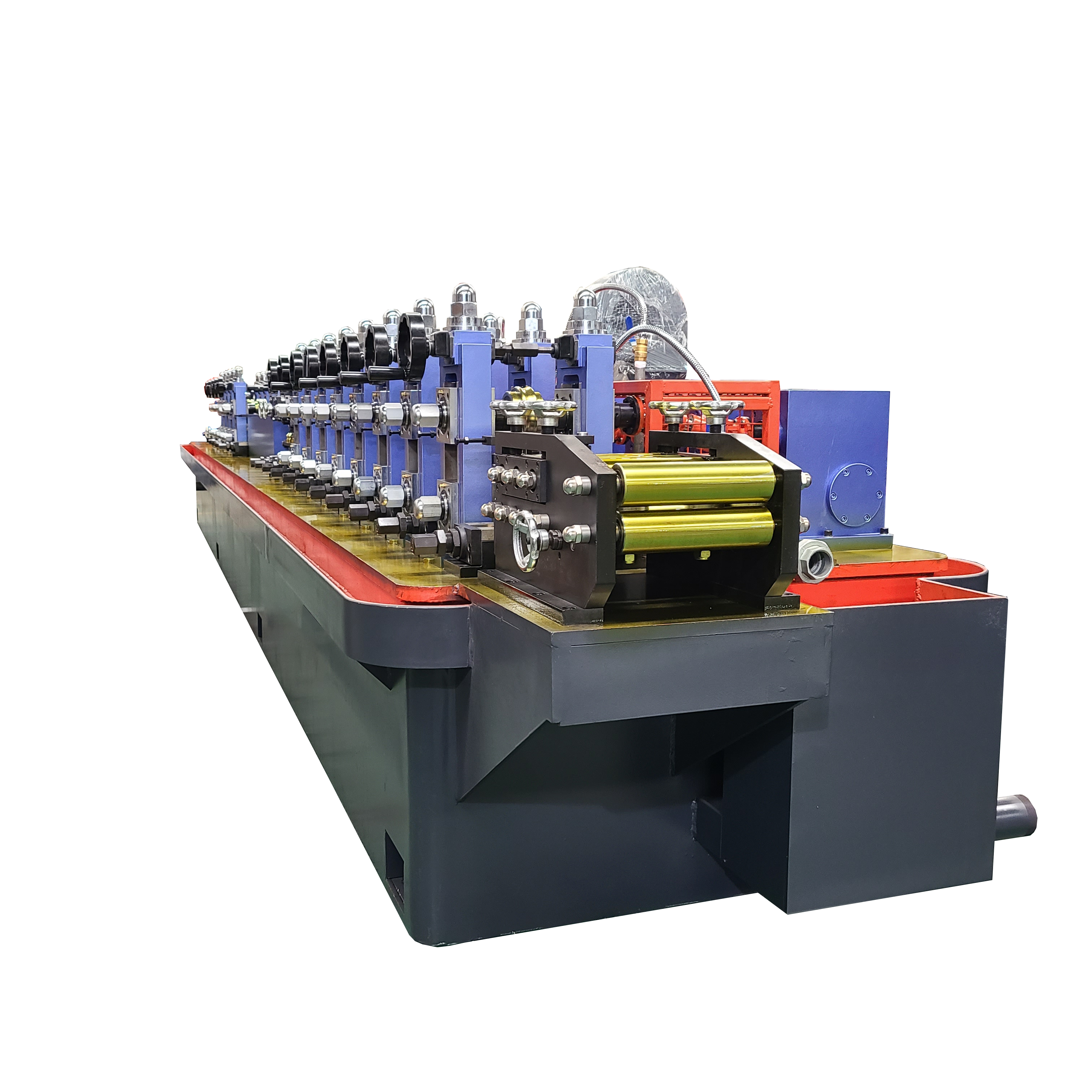

গুনিয়তম জি-আই পাইপ তৈরির মেশিন

গুনগত জি আই পাইপ তৈরি যন্ত্রটি আধুনিক উৎপাদন প্রযুক্তির এক চূড়ান্ত বিন্দু নিরূপণ করে, যা অসাধারণ সঠিকতা এবং ভরসার সাথে গ্যালভানাইজড আয়রন পাইপ উৎপাদনের জন্য ডিজাইন করা হয়েছে। এই উন্নত যন্ত্রটি একটি সম্পূর্ণ উৎপাদন লাইন অন্তর্ভুক্ত করে যা কাঁচামাল ফিডিং থেকে শুরু করে চূড়ান্ত পাইপ গঠন পর্যন্ত সবকিছু প্রক্রিয়া করে। যন্ত্রটি সর্বশেষ রোল ফর্মিং প্রযুক্তি ব্যবহার করে যা নির্দিষ্ট পাইপ আকৃতি এবং পৃষ্ঠ গুনগত মান নিশ্চিত করে। এর স্বয়ংক্রিয় নিয়ন্ত্রণ পদ্ধতি উৎপাদন প্রক্রিয়ার মাঝে নির্দিষ্ট প্যারামিটার বজায় রাখে, যার মধ্যে রয়েছে কাঁচামালের মোটা, পাইপের ব্যাস এবং গ্যালভানাইজড সঙ্গতি। যন্ত্রটি একাধিক পর্যায়ের মাধ্যমে স্টিল স্ট্রিপ কার্যকরভাবে প্রক্রিয়া করে, যার মধ্যে রয়েছে ডিকয়োইলিং, ফর্মিং, ওয়েল্ডিং এবং গ্যালভানাইজিং, সমস্ত সময় কঠোর গুনগত নিয়ন্ত্রণ বজায় রেখে। পাইপের বিশেষতার উপর নির্ভর করে প্রতি মিনিটে ৪০ মিটার পর্যন্ত উৎপাদন গতি পৌঁছাতে পারে, এই যন্ত্রটি দক্ষতা এবং গুনগত মান উভয়ই প্রদান করে। একীভূত গুনগত নিয়ন্ত্রণ পদ্ধতি উৎপাদনের প্রতিটি দিক পরিবেশন করে, ওয়েল্ডের সংরক্ষণ থেকে শুরু করে কোটিং মোটা পর্যন্ত, যেন প্রতিটি পাইপ আন্তর্জাতিক মানদণ্ড অনুসরণ করে। যন্ত্রটির বহুমুখীতা দিয়ে ১৫মিমি থেকে ২০০মিমি ব্যাসের মধ্যে পাইপ উৎপাদনের অনুমতি দেওয়া হয়, যা কাঠামো থেকে শুরু করে বাস্তবায়ন উন্নয়ন পর্যন্ত বিভিন্ন শিল্পীয় প্রয়োগের জন্য উপযুক্ত। উন্নত নিরাপত্তা বৈশিষ্ট্যসমূহ অপারেটরদেরকে সুরক্ষিত রাখে এবং অপ্টিমাল উৎপাদন শর্তাবলী বজায় রাখে, এবং যন্ত্রটির দৃঢ় নির্মাণ দীর্ঘ সময়ের জন্য ভরসা এবং কম রকম রক্ষণাবেক্ষণের প্রয়োজনীয়তা নিশ্চিত করে।