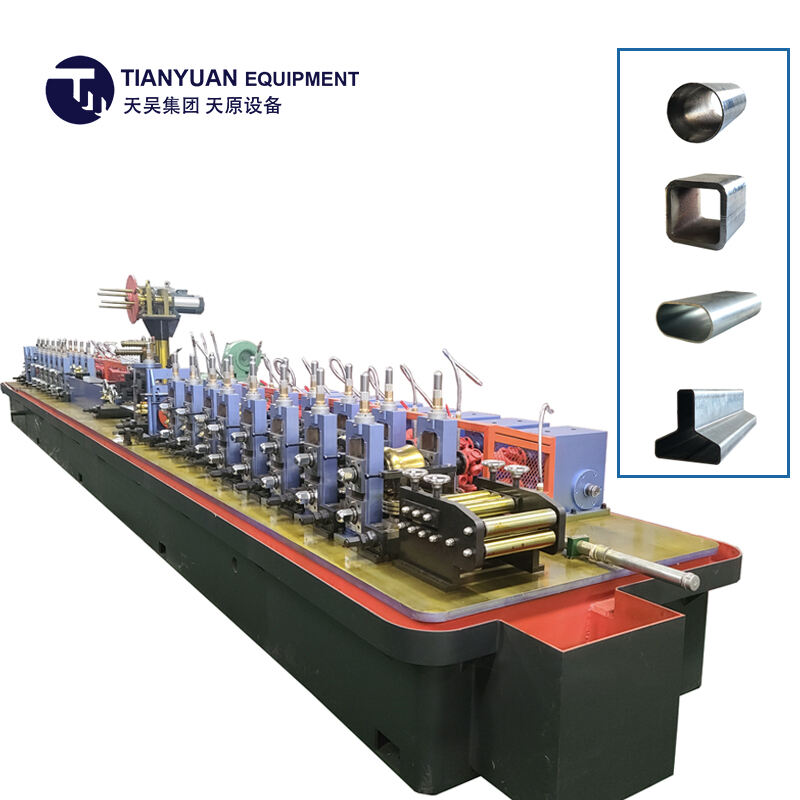

snadno udržitelná hf svarovaná potrubní linka

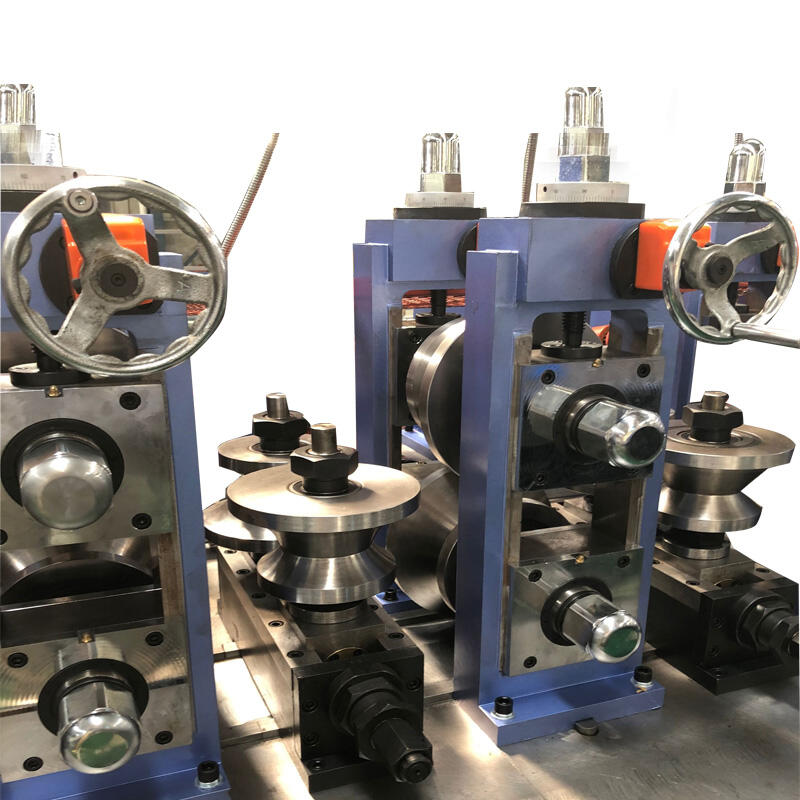

Snadno údržbové HF spávkové dílny představují moderní řešení v oblasti technologie výroby trubek. Tento pokročilý systém kombinuje přesnou inženýrství s uživatelsky přátelským designem, aby efektivně a konzistentně vyráběl kvalitní spálené trubky. Dílna funguje prostřednictvím sofistikovaného procesu vysokofrekvenčního spojování, kde se plechové pásy formují, spojují a dokončují v nepřetržité produkční lince. Klíčové technologické prvky zahrnují automatizované mechanismy na krmení pásem, přesné stanice na formování, pokročilé HF spávkové jednotky a integrované systémy kontroly kvality. Design dílny zdůrazňuje přístupnost pro údržbu, s modulárními komponenty, které lze snadno prohlédnout a obsloužit. Umožňuje různé specifikace trubek, obvykle vyrábí trubky o průměru od 20 mm do 165 mm a s tloušťkami stěny od 1,2 mm do 6 mm. Systém začleňuje inteligentní monitorovací technologii, která sleduje produkční parametry v reálném čase, aby zajistila konzistentní kvalitu spoje a rozměrovou přesnost. Aplikace sahají napříč více odvětvími, včetně stavebnictví, automobilového průmyslu, výroby nábytku a zemědělského zařízení. Univerzálnost dílny umožňuje rychlé změny velikosti a úpravy materiálových kategorií, což ji činí vhodnou jak pro výrobu v velkém měřítku, tak i pro specializované objednávky.