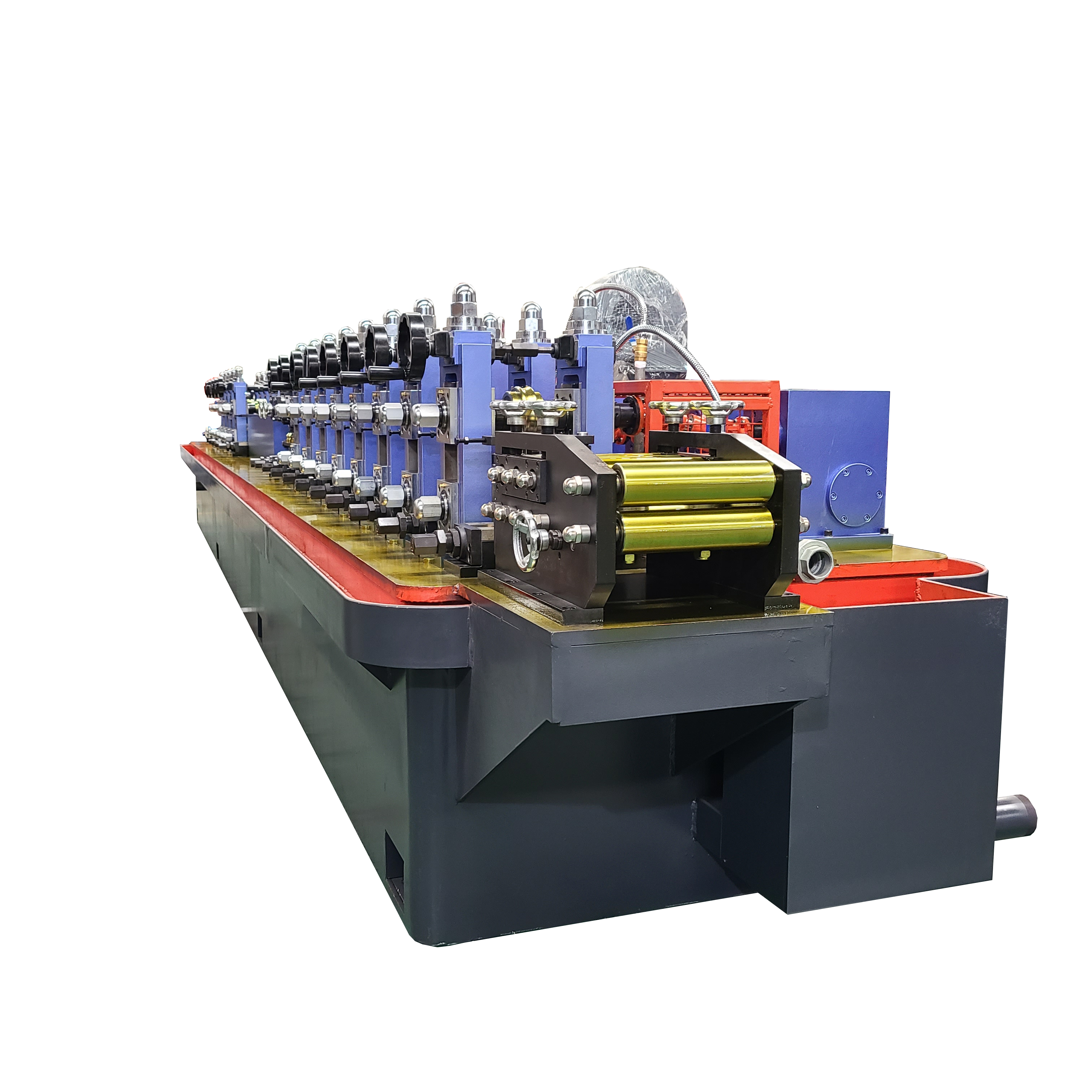

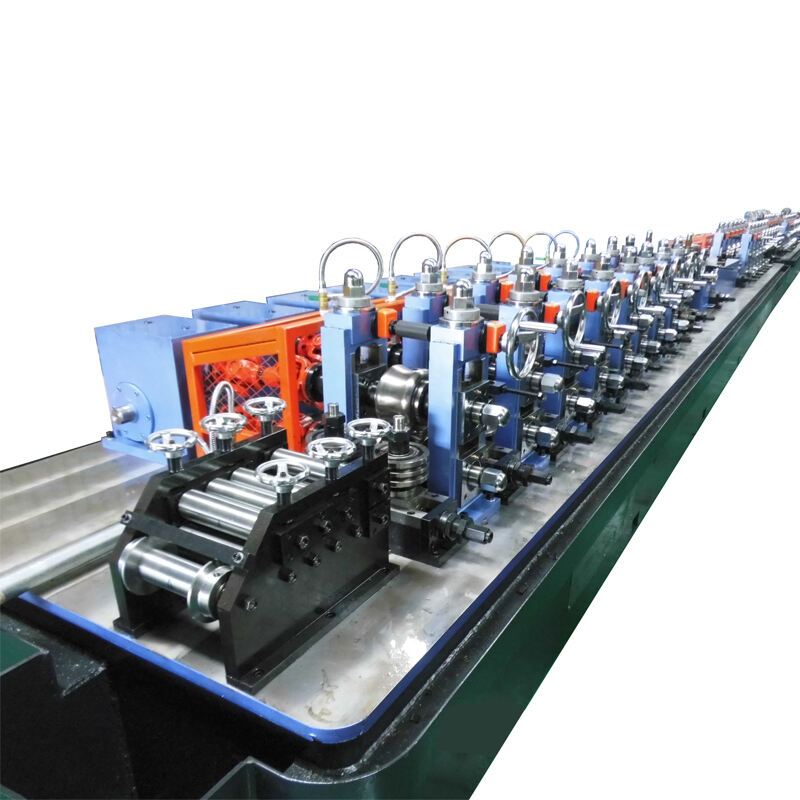

mesin pembentuk pipa dengan biaya rendah

Mesin pembentuk pipa biaya rendah mewakili perkembangan signifikan dalam teknologi manufaktur pipa yang efisien dan ekonomis. Peralatan serbaguna ini mengubah lembaran logam datar menjadi pipa yang terbentuk dengan presisi melalui proses gulungan sistematis dan pengelasan. Mesin ini dilengkapi dengan sistem kontrol canggih yang memastikan kualitas konsisten sambil tetap menjaga efektivitas biaya. Fitur otomatisasinya memungkinkan produksi berkelanjutan dengan intervensi operator minimal, menghasilkan tingkat produksi lebih tinggi dan pengurangan biaya tenaga kerja. Konstruksi yang kokoh dari mesin ini mencakup rol pembentuk yang dirancang dengan presisi, kontrol ukuran otomatis, dan sistem pengelasan terpadu yang bekerja bersama-sama untuk menghasilkan pipa dengan berbagai diameter dan ketebalan. Fitur teknologi yang menonjol termasuk kecepatan pembentukan yang dapat disesuaikan, antarmuka kontrol digital, dan sistem alat pergantian cepat yang memudahkan pergantian produk yang cepat. Peralatan ini sangat cocok untuk operasi manufaktur skala kecil hingga menengah, menjadikannya pilihan ideal bagi perusahaan yang ingin memulai atau memperluas kemampuan produksi pipanya. Aplikasinya mencakup berbagai industri, termasuk konstruksi, pertanian, otomotif, dan pengembangan infrastruktur. Kemampuan mesin untuk menangani berbagai jenis material dan ketebalan membuatnya sangat bernilai bagi produsen yang melayani segmen pasar yang beragam.