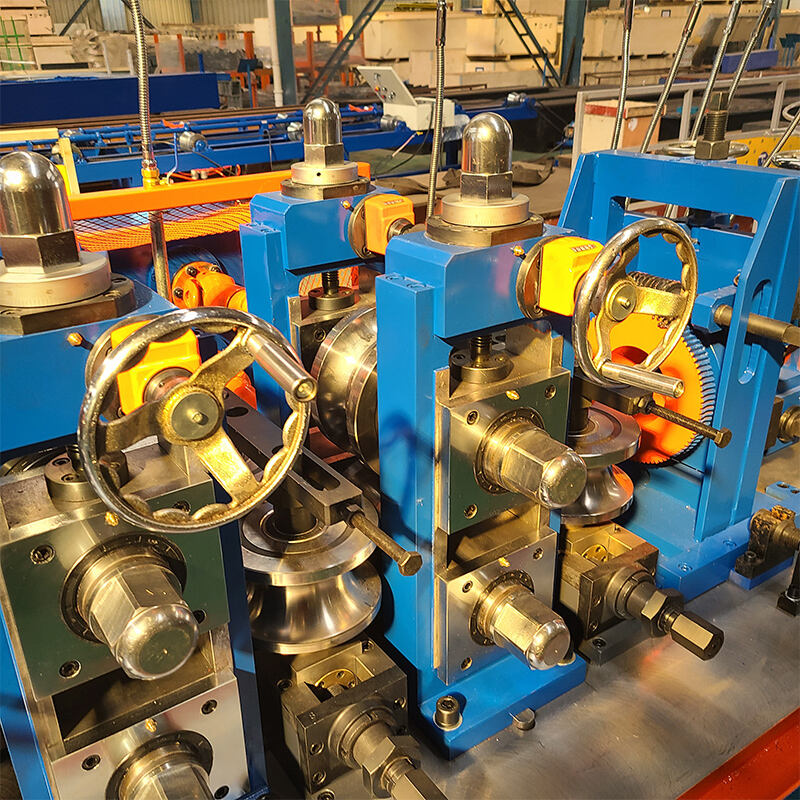

mesin pembuatan tabung ms terbaru

Mesin pembuat pipa MS terbaru mewakili terobosan dalam teknologi fabrikasi logam, menawarkan presisi dan efisiensi tanpa precedence dalam memproduksi pipa baja ringan. Peralatan canggih ini menggabungkan sistem kontrol digital lanjutan dan fitur otomatisasi yang memastikan keluaran kualitas konsisten. Mesin ini menggunakan teknologi las frekuensi tinggi, mampu memproses lembaran baja menjadi pipa yang terbentuk sempurna dengan diameter berkisar dari 20mm hingga 76mm. Sistem pembentukan terbarunya mencakup beberapa stasiun pembentukan yang secara bertahap membentuk material ke dalam bentuk tabung yang diinginkan, sambil mempertahankan toleransi dimensi yang ketat. Sistem pengendalian kualitas terintegrasi memiliki kemampuan pemantauan waktu nyata, mendeteksi setiap penyimpangan dalam parameter las atau sifat material. Dengan kecepatan produksi hingga 120 meter per menit, mesin ini secara signifikan meningkatkan efisiensi manufaktur. Sistem ini juga mencakup komponen penanganan material otomatis, mengurangi intervensi manual dan meningkatkan keselamatan tempat kerja. Desainnya yang fleksibel memungkinkan perubahan ukuran yang cepat dan waktu setup minimal antara berbagai jalur produksi, membuatnya ideal untuk produksi massal maupun pesanan khusus. Aplikasi mesin ini meliputi berbagai industri, termasuk konstruksi, pembuatan furnitur, komponen otomotif, dan proyek-proyek rekayasa mekanik.