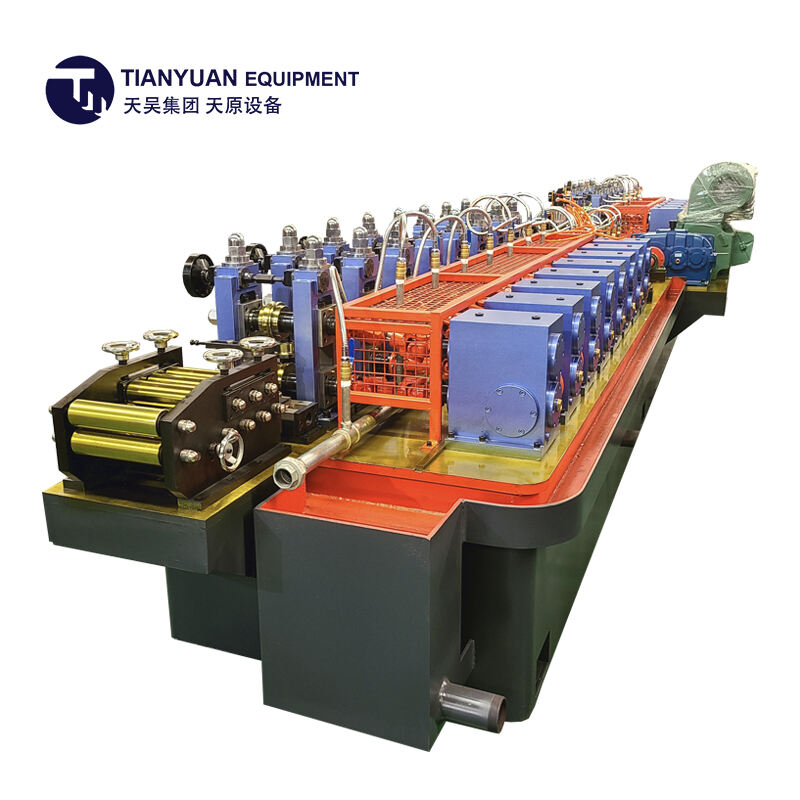

안전하고 신뢰할 수 있는 HF 용접 파이프 밀

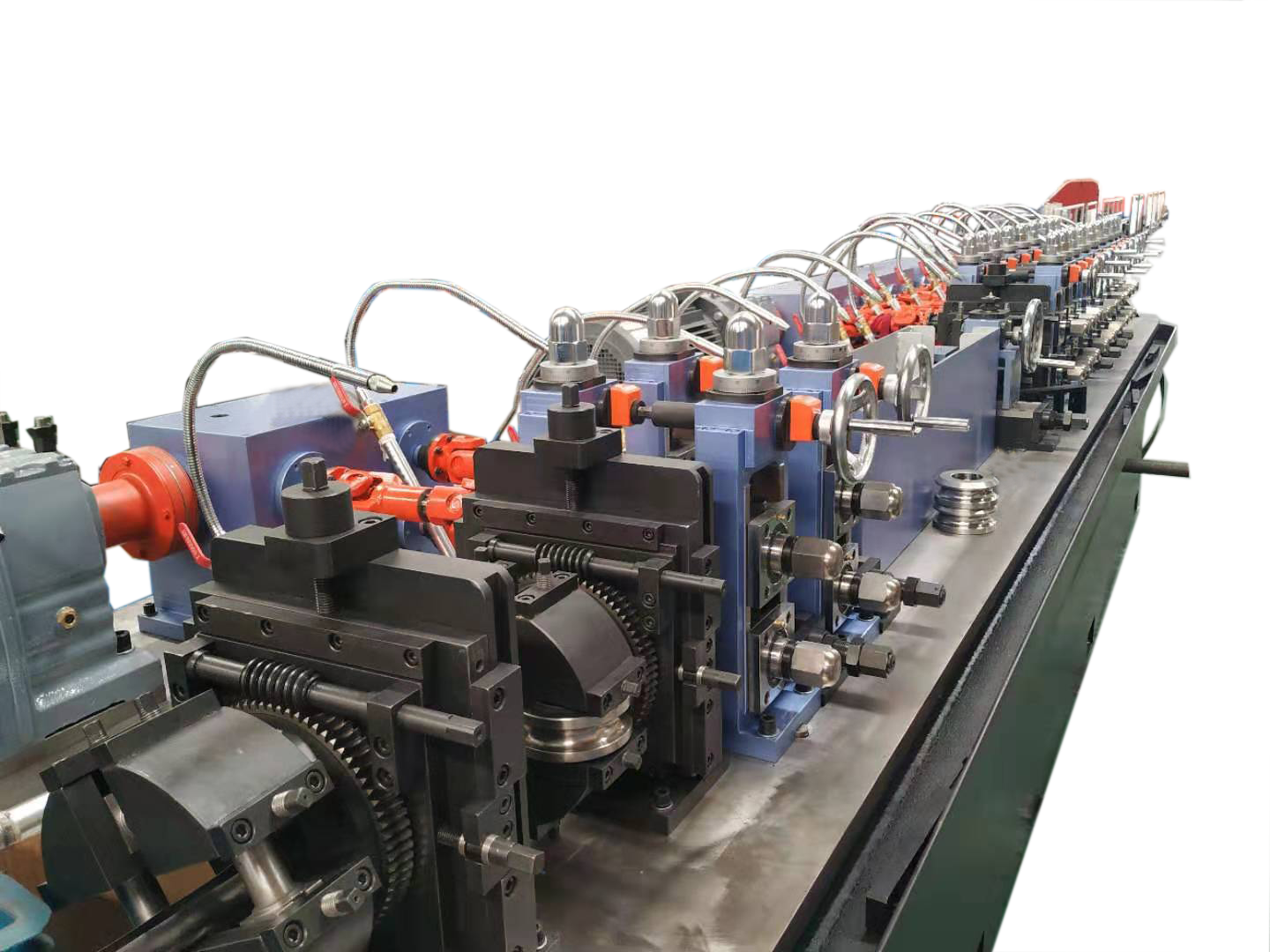

HF 용접 파이프 밀은 고급스러운 용접 강관을 뛰어난 정확도와 효율로 생산하기 위해 설계된 최첨단 제조 솔루션입니다. 이 진보된 시스템은 연속적인 파이프 생산을 가능하게 하며, 우수한 용접 신뢰성과 치수 정확성을 제공하는 최신 고주파 용접 기술을 통합합니다. 밀은 스트립 공급에서 시작하여 정밀한 성형, 고주파 용접 및 포괄적인 품질 관리 절차를 거치는 복잡한 과정으로 운영됩니다. 시스템의 자동화된 제어 장치는 최적의 생산 속도를 유지하면서 일관된 파이프 품질을 보장합니다. 주요 기술적 특징에는 선진 성형 도구, 정밀한 온도 제어 시스템 및 통합된 품질 모니터링 장비가 포함됩니다. 밀은 다양한 파이프 사양을 수용하며, 일반적으로 직경 20mm에서 219mm 사이, 벽 두께는 1.2mm에서 8mm 사이의 파이프를 생산합니다. 응용 분야는 건설, 자동차, 가구 제조, 인프라 개발 등 여러 산업에 걸쳐 있습니다. 밀의 다재다능성은 라운드 튜브와 스퀘어 튜브 모두를 생산할 수 있어 다양한 산업적 용도에 매우 유용합니다. 안전 기능에는 비상 정지 시스템, 보호 장벽 및 자동화된 재료 취급 장비가 포함되어 있어 작업자의 안전을 확보하면서 생산성을 유지합니다.