ເຄື່ອງຊະນະທຸບເຫຼັກຄົນຕ່າງປະເທດພິเศດ

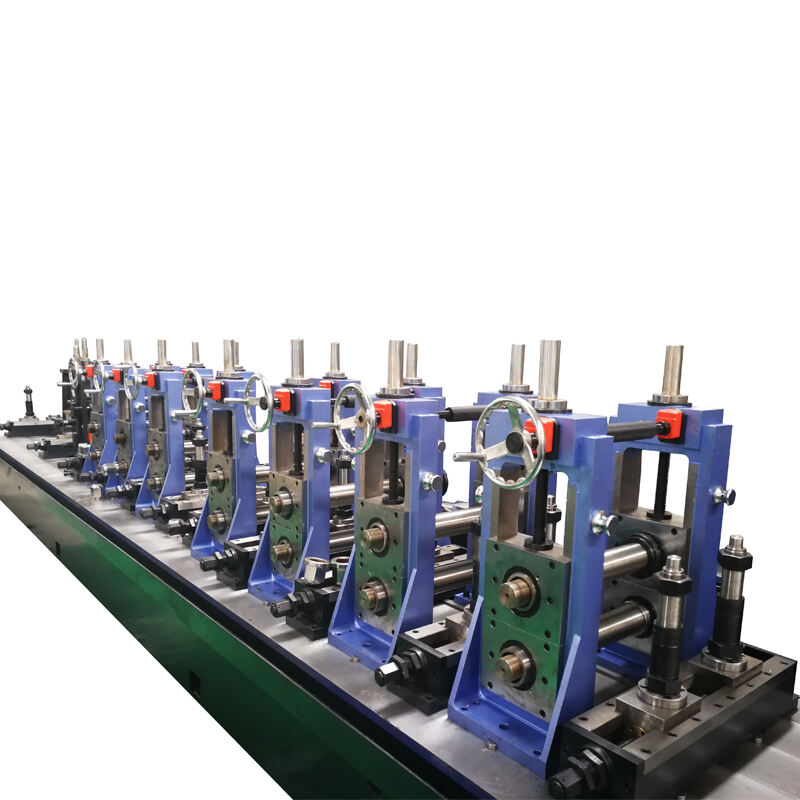

ເຄື່ອງປະຕູ້ທີ່ມີຄຸນພາບສູງສຳລັບການຊົ່ງແຜ່ນເຫຼືອງເຮືອນແມ່ນສະຫນິດຂອງເทັກນົໂລຊີແມ່ນໄປໜ້າໃນປະຈຸບັນ ການດີไซນ໌ຂອງມັນແມ່ນເພື່ອຜົນຕໍ່ເຫຼືອງເຮືອນທີ່ມີຄວາມຖືກຕ້ອງແລະຄຸນພາບສູງສຳລັບການໃຊ້ງານອຸດົມສາຫະພັນທີ່ຕ່າງກັນ. ເຄື່ອງມືຂຶ້ນກັບນີ້ແມ່ນການປະສານກັນຂອງຫົວໜ້າການປະຕູ້ຫຼາຍ, ທີ່ເປັນການສົ່ງເສີມ, ການແບບ, ການແຫັງ, ແລະການສົ່ງສຸດທ້າຍ, ລ້ານທີ່ຢູ່ໃນເສັ້ນຜົນຕໍ່ອັດຕະໂມມັດ. ເຄື່ອງມືນີ້ໃຊ້ລະບົບຄື້ຍຄົງທີ່ສຸດສຳລັບການເກັບຄຸນພາບທີ່ເທົ່າທຽມກັນເoulos ຄວາມສູງຂອງການປະຕູ້, ເນື່ອງຈາກການແນະນຳຂອງເຫຼືອງເຮືອນແມ່ນສະຖິຕາມຄະແນນທີ່ເປັນການເປັນການ. ອິດສະຫຼະກອນຂອງມັນແມ່ນການປະຕູ້ທີ່ມີຄວາມຖືກຕ້ອງທີ່ປະຕູ້ກັບກັນ, ທີ່ເຮັດໃຫ້ເຫຼືອງເຮືອນເປັນເຫຼືອງເຮືອນທີ່ມີຄຸນພາບສູງສູງ, ແລະມີຄວາມຖືກຕ້ອງ. ເທັກນົໂລຊີນີ້ແມ່ນການປະສານກັນຂອງການແຫັງທີ່ມີຄວາມແຂງແລະບໍ່ມີເສັ້ນແຍກ, ເນື່ອງຈາກລະບົບຄື້ຍຄົງທີ່ສຸດສຳລັບການເກັບຄຸນພາບ, ເນື່ອງຈາກການເບິ່ງເຫັນຂອງການປະຕູ້. ເຄື່ອງມືນີ້ສາມາດຜົນຕໍ່ເຫຼືອງເຮືອນໃນຫຼາຍແຫວນແລະຄວາມໜັງທີ່ຕ່າງກັນ, ເນື່ອງຈາກມັນມີຄວາມຫຼາຍຫຼາຍທີ່ຈະສາມາດເປັນການປະຕູ້ທີ່ຕ່າງກັນ. ການອັດຕະໂມມັດຂອງລະບົບນີ້ເປັນການຫຼຸດລົງຂອງຄວາມຜິດພາດຂອງມະນຸດ, ເນື່ອງຈາກມັນສາມາດເປັນການປະຕູ້ທີ່ມີຄວາມສູງສຸດ, ເນື່ອງຈາກມັນເປັນການປະຕູ້ທີ່ສູງສຸດ. ແລະ ເຄື່ອງມືນີ້ມີລະບົບຄື້ຍຄົງທີ່ສຸດສຳລັບການເກັບຄຸນພາບ, ເນື່ອງຈາກມັນສາມາດເປັນການປະຕູ້ທີ່ສູງສຸດ.