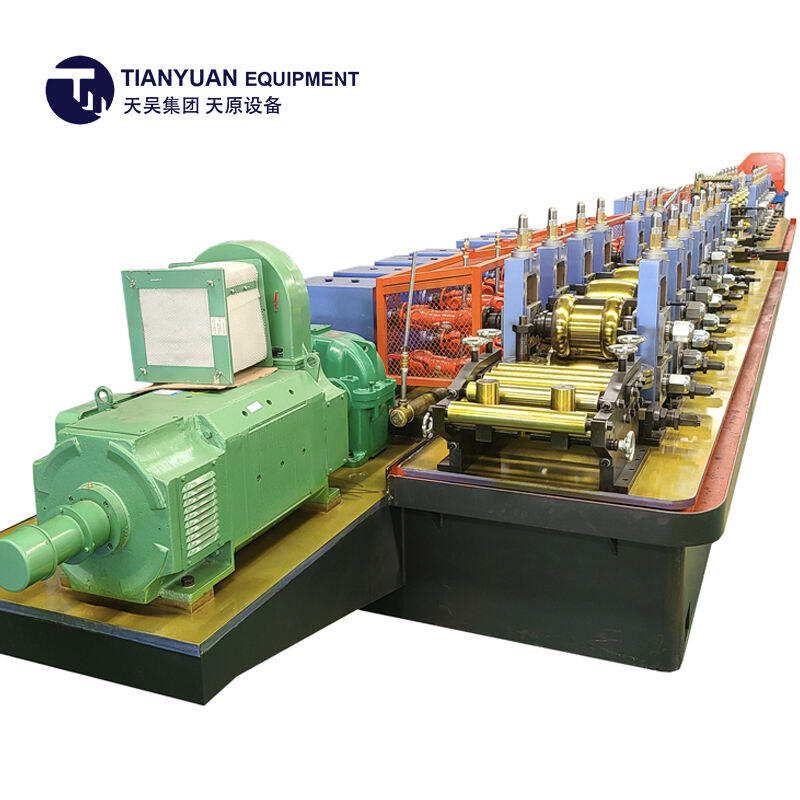

máquina de fabricação de tubos ms personalizável

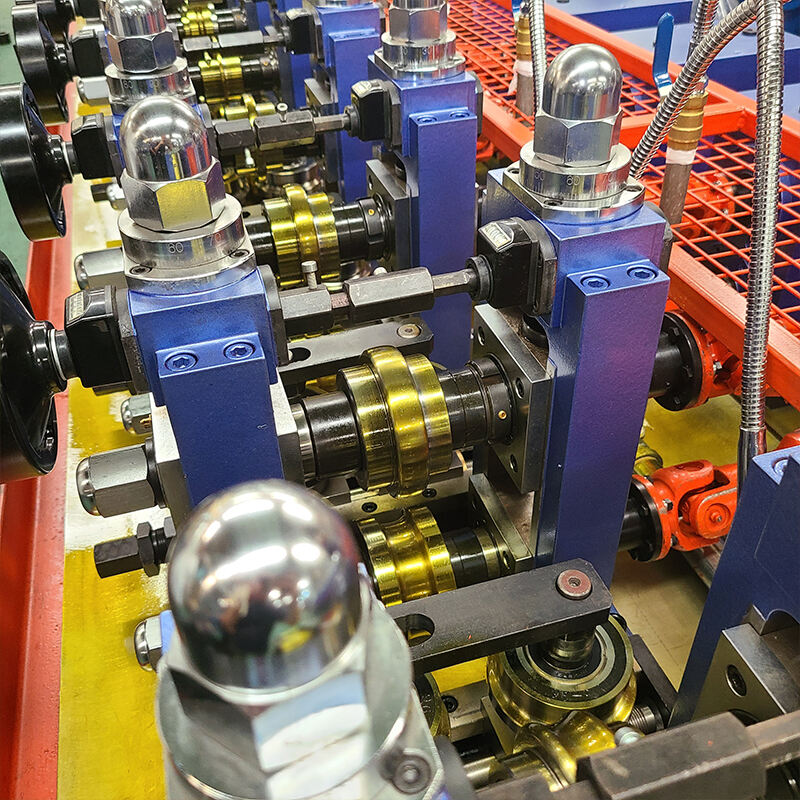

A máquina personalizável de fabricação de tubos MS representa uma inovação na tecnologia de fabricação moderna, oferecendo flexibilidade e precisão sem paralelos na produção de tubos de aço macio. Este equipamento avançado incorpora sistemas de controle de ponta que permitem aos operadores ajustar vários parâmetros, incluindo diâmetro do tubo, espessura da parede e comprimento de acordo com requisitos específicos. A máquina possui uma seção de formação robusta com várias estações de rolos que gradualmente moldam tiras de aço planas em tubos cilíndricos perfeitos, mantendo uma qualidade consistente durante todo o processo de produção. Seu sistema de solda automatizado garante costuras fortes e confiáveis, e os mecanismos integrados de controle de qualidade monitoram continuamente os parâmetros de produção para manter altos padrões. A versatilidade da máquina permite a produção de tubos com diâmetros variando de 20mm a 219mm, tornando-a adequada para várias aplicações industriais, incluindo construção, automotivo, fabricação de móveis e engenharia mecânica. A interface amigável ao usuário simplifica a operação e o ajuste de parâmetros, enquanto o design modular da máquina facilita a manutenção e as atualizações. Recursos avançados de segurança, incluindo sistemas de parada de emergência e guarda-protectores, garantem a segurança do operador enquanto mantêm a eficiência máxima de produção. A capacidade da máquina de lidar com diferentes graus de aço e espessuras, combinada com sua alta velocidade de produção de até 40 metros por minuto, a torna um ativo valioso para fabricantes que buscam atender às diversas demandas do mercado.