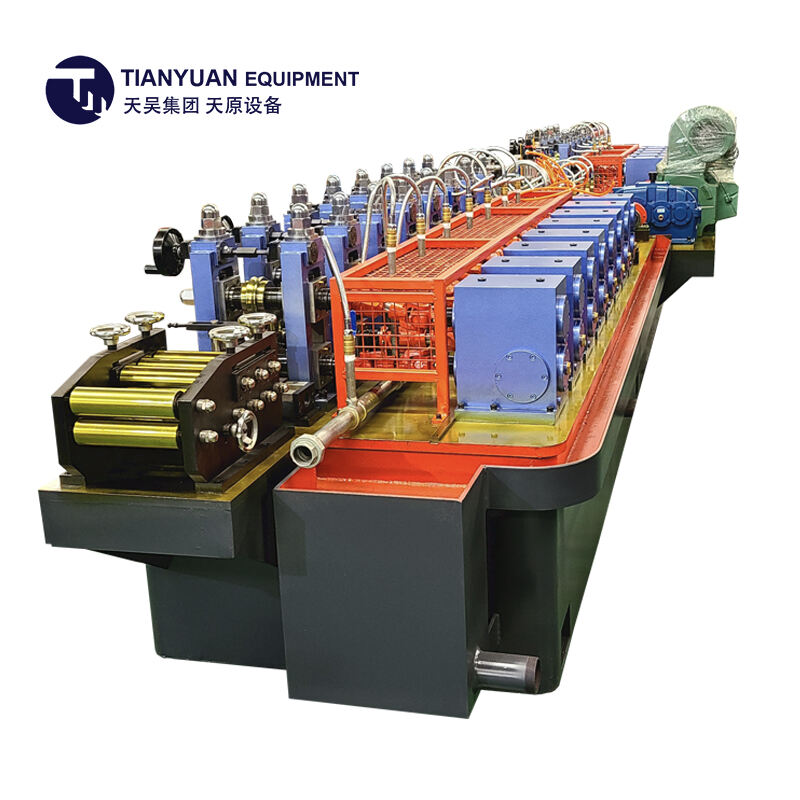

máquina durável para formar tubos

A máquina de formação de tubos durável representa um ponto alto da tecnologia de fabricação moderna, projetada para produzir tubos de alta qualidade com consistência e confiabilidade excepcionais. Este equipamento avançado utiliza um sofisticado processo de formação a frio que transforma chapas metálicas planas em tubos cilíndricos perfeitos através de uma série de estações de formação calibradas com precisão. A máquina incorpora sistemas de controle de última geração que garantem precisão dimensional e qualidade de superfície durante todo o processo de produção. Ela possui parâmetros de formação ajustáveis para acomodar vários diâmetros de tubos, espessuras de parede e especificações de materiais, tornando-a versátil para diferentes aplicações industriais. A construção robusta da máquina, combinada com componentes de primeira linha, garante uma vida operacional prolongada e requisitos mínimos de manutenção. O sistema inclui mecanismos automáticos de alimentação de material, estações de corte precisas e tecnologia de solda avançada para um fluxo de produção contínuo. Uma atenção especial foi dada ao design das rolos de formação, que são fabricados em aço endurecido e engenhados com precisão para minimizar o atrito e garantir o fluxo ótimo do material. O sistema de controle inteligente da máquina monitora todos os aspectos do processo de produção, desde o alinhamento do material até a inspeção do produto final, garantindo uma saída de qualidade consistente. Este equipamento é particularmente valioso em indústrias que exigem produção em grande volume de tubos, como construção, desenvolvimento de infraestrutura e fabricação industrial.